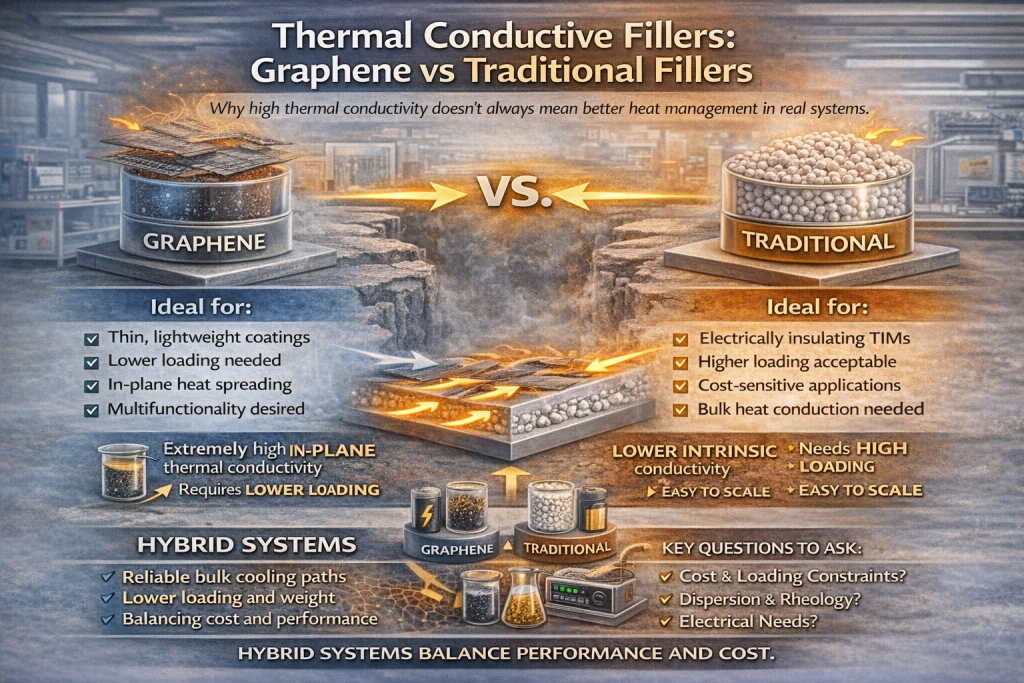

Thermal Conductive Fillers: Graphene vs Traditional Fillers

Why high thermal conductivity on paper does not always mean better heat management in real systems.

The common assumption

When engineers look at datasheets, the logic seems simple:

Higher intrinsic thermal conductivity

= better heat dissipation

Graphene immediately stands out.

Its thermal conductivity is orders of magnitude higher than many traditional fillers.

Yet in practice, replacing conventional fillers with graphene does not automatically deliver better thermal performance.

The reason lies in how heat actually moves through composite systems.

Traditional thermal fillers: why they are still widely used

Traditional fillers such as:

-

Aluminum oxide (Al₂O₃)

-

Aluminum nitride (AlN)

-

Boron nitride (BN)

-

Magnesium oxide (MgO)

are widely used not because they are advanced, but because they are:

-

Predictable

-

Process-friendly

-

Cost-stable

-

Electrically insulating

-

Easy to scale

They form bulk thermal pathways by high loading, allowing heat to move through direct particle-to-particle contact.

This approach works reliably in:

-

Thermal interface materials (TIMs)

-

Potting compounds

-

Gap fillers

-

Encapsulation materials

Graphene as a thermal filler: what’s different

Graphene behaves very differently from traditional fillers.

Its advantages:

-

Extremely high in-plane thermal conductivity

-

High aspect ratio

-

Ability to form thermal pathways at lower loading

-

Potential multifunctionality (thermal + mechanical + barrier)

But graphene also introduces challenges:

-

Heat transfer is anisotropic (direction-dependent)

-

Interfacial thermal resistance matters more

-

Dispersion and orientation strongly affect performance

-

Electrical conductivity may be undesirable in some systems

Graphene does not work as a simple “drop-in replacement.”

How heat actually flows in composites

In real systems, heat flow depends on:

-

Filler–filler contact

-

Filler–matrix interfaces

-

Orientation and alignment

-

Packing density

-

Processing method

Traditional fillers rely on dense packing.

Graphene relies on network formation and orientation.

If graphene sheets are poorly dispersed or randomly oriented, much of their intrinsic thermal advantage is lost.

When traditional fillers make more sense

Traditional fillers are often the better choice when:

-

Electrical insulation is mandatory

-

Very high filler loading is acceptable

-

Cost sensitivity is high

-

Processes are already optimized for spherical or platelet fillers

-

Isotropic heat conduction is required

In many industrial thermal systems, reliability and consistency outweigh peak performance.

When graphene adds real thermal value

Graphene becomes valuable when:

-

Weight reduction is important

-

Lower filler loading is required

-

Thermal spreading (in-plane heat dissipation) matters

-

Mechanical reinforcement is also needed

-

Space constraints limit filler volume

Examples include:

-

Thin thermal coatings

-

Structural heat-spreading layers

-

Lightweight electronics

-

Multi-functional thermal–mechanical systems

In these cases, graphene is not replacing traditional fillers — it is changing the design approach.

Hybrid systems: the practical solution

In many successful applications, graphene is used together with traditional fillers.

Hybrid systems allow:

-

Bulk heat transfer via traditional fillers

-

Thermal spreading via graphene

-

Reduced overall loading

-

Improved mechanical stability

This approach balances performance, cost, and processability.

Scale-up and process reality

At pilot and industrial scale, the key questions become:

-

Can the filler system be dispersed consistently?

-

Does it maintain stable rheology?

-

Does it fit existing equipment?

-

Does it meet electrical and safety requirements?

Graphene’s value only appears when these factors are addressed early.

A practical decision framework

Use traditional fillers when:

-

Insulation is critical

-

High loading is acceptable

-

Cost and scalability dominate

Use graphene when:

-

Thermal spreading is needed

-

Weight and thickness matter

-

Multi-functionality is required

Use hybrid fillers when:

-

System-level optimization is the goal

Beyond numbers on a datasheet

Thermal conductivity values alone do not define performance.

What matters is:

-

How heat moves through the system

-

How materials interact

-

How processes scale

Graphene is a powerful thermal tool — but only when applied with a clear understanding of system design.