Thermal Contact Resistance – Why Interfaces Matter More Than Bulk Conductivity

The Real Bottleneck in Thermal Management

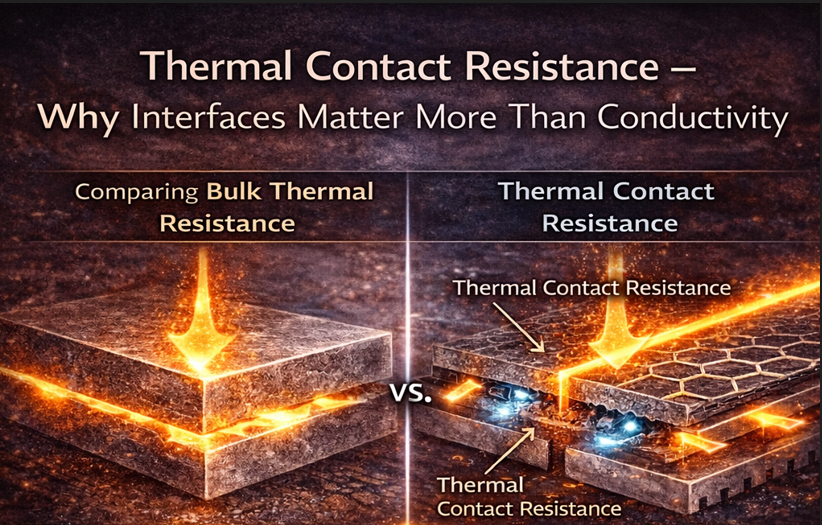

In thermal management, bulk thermal conductivity (W/m·K) is often treated as the primary indicator of performance. Higher conductivity values are commonly associated with better heat dissipation.

In real engineering systems, however, thermal performance is rarely limited by bulk material properties alone. Instead, thermal contact resistance (TCR) at material interfaces frequently accounts for the largest portion of total thermal resistance.

Whether in power electronics, energy storage systems, LEDs, or industrial equipment, heat must cross multiple interfaces before reaching a heat sink. If these interfaces are inefficient, even materials with excellent bulk conductivity cannot deliver their full potential.

What Is Thermal Contact Resistance?

Thermal contact resistance refers to the resistance to heat flow that occurs at the interface between two solid surfaces in contact.

Even surfaces that appear smooth at the macroscopic level are rough at the microscopic scale. When two solids are pressed together, contact occurs only at discrete asperities, while microscopic air gaps remain trapped between them. Since air has extremely low thermal conductivity, these gaps significantly impede heat transfer.

Thermal contact resistance arises from:

-

Surface roughness and flatness mismatch

-

Trapped air and voids at the interface

-

Limited real contact area

-

Mechanical and thermal instability during operation

Why Interfaces Matter More Than Bulk Conductivity

Heat Transfer Is a Series Resistance Problem

In practical thermal assemblies, heat flows through a series of resistances:

Heat source → TIM → Interface → Substrate → Interface → Heat sink

The total thermal resistance is dominated by the largest resistance in this chain. In many cases, interface resistance exceeds the bulk resistance of the thermal material itself.

As a result:

-

Doubling bulk thermal conductivity may yield only marginal improvement

-

Reducing thermal contact resistance can significantly lower overall system temperature

High Bulk Conductivity Does Not Guarantee Low Thermal Resistance

Materials with high intrinsic thermal conductivity often perform poorly in real assemblies due to:

-

Poor surface wetting

-

Insufficient mechanical compliance

-

Incomplete contact under low clamping pressure

This is why softer, more conformable materials with moderate bulk conductivity frequently outperform rigid, high-k materials in practical applications.

Key Factors Affecting Thermal Contact Resistance

Surface Roughness and Flatness

Rough or uneven surfaces reduce the real contact area, increasing air gaps and constriction resistance. Improving surface finish or using interface materials that conform to surface asperities is essential.

Mechanical Compliance of the Interface Material

Compliant materials deform under pressure, filling micro-scale voids and improving contact quality. This explains why greases, gels, and soft pads often reduce TCR more effectively than rigid solids.

Bond Line Thickness

Excessive bond line thickness increases thermal path length, while insufficient thickness can prevent proper surface coverage. Optimizing bond line thickness is critical to balancing conformity and thermal resistance.

Filler Morphology and Dispersion

Traditional spherical fillers require high loading levels and often create point-to-point contacts. In contrast, high-aspect-ratio fillers such as CNTs and graphene can bridge gaps more effectively and form continuous thermal pathways at lower loading levels.

How CNTs and Graphene Reduce Thermal Contact Resistance

CNTs as Nano-Scale Thermal Bridges

Carbon nanotubes exhibit excellent axial thermal conductivity and high aspect ratios. In thermal interfaces, CNTs act as nano-scale bridges that span surface asperities and micro-gaps, improving through-plane heat transfer.

Their elastic nature also helps maintain contact under thermal cycling and mechanical stress.

Graphene for Lateral Heat Spreading

Graphene sheets provide exceptional in-plane thermal conductivity, allowing heat to spread laterally at interfaces. This reduces localized hot spots and improves heat distribution before heat crosses into adjacent layers.

Hybrid CNT–Graphene Interface Networks

Hybrid CNT–graphene systems combine vertical heat transport and lateral heat spreading. CNTs reduce interfacial gaps, while graphene distributes heat efficiently across the interface.

These hybrid networks often achieve lower thermal contact resistance at lower filler loading compared to single-filler systems, making them attractive for thin, lightweight thermal solutions.

Why Bulk Conductivity Alone Can Be Misleading

Datasheet thermal conductivity values are often measured under ideal conditions:

-

Perfect surface contact

-

Uniform pressure

-

Controlled laboratory environments

In real applications, thermal cycling, vibration, aging, and surface contamination degrade interface quality over time. A material with slightly lower bulk conductivity but stable, low contact resistance often delivers better long-term performance.

Practical Design Guidelines

When designing thermal interfaces:

-

Prioritize reducing interface resistance before increasing bulk conductivity

-

Select materials with good surface conformity and mechanical stability

-

Optimize filler dispersion rather than simply increasing filler content

-

Evaluate performance under realistic pressure and operating conditions

Measuring total thermal resistance is more meaningful than comparing bulk conductivity values alone.

Applications Where Thermal Contact Resistance Is Critical

-

Battery modules and energy storage systems

-

Power electronics and inverters

-

LEDs and lighting systems

-

EV thermal management

-

Industrial control and automation equipment

In these systems, interface performance directly impacts reliability, efficiency, and lifetime.

Thermal Management Is an Interface Engineering Problem

Modern thermal management is no longer just about selecting materials with the highest conductivity. It is about engineering interfaces that allow heat to move efficiently across real, imperfect surfaces.

By understanding and minimizing thermal contact resistance, engineers can achieve greater thermal performance, improved reliability, and more efficient system designs—often without increasing material cost or complexity.

In practical thermal systems, interfaces matter more than bulk conductivity.