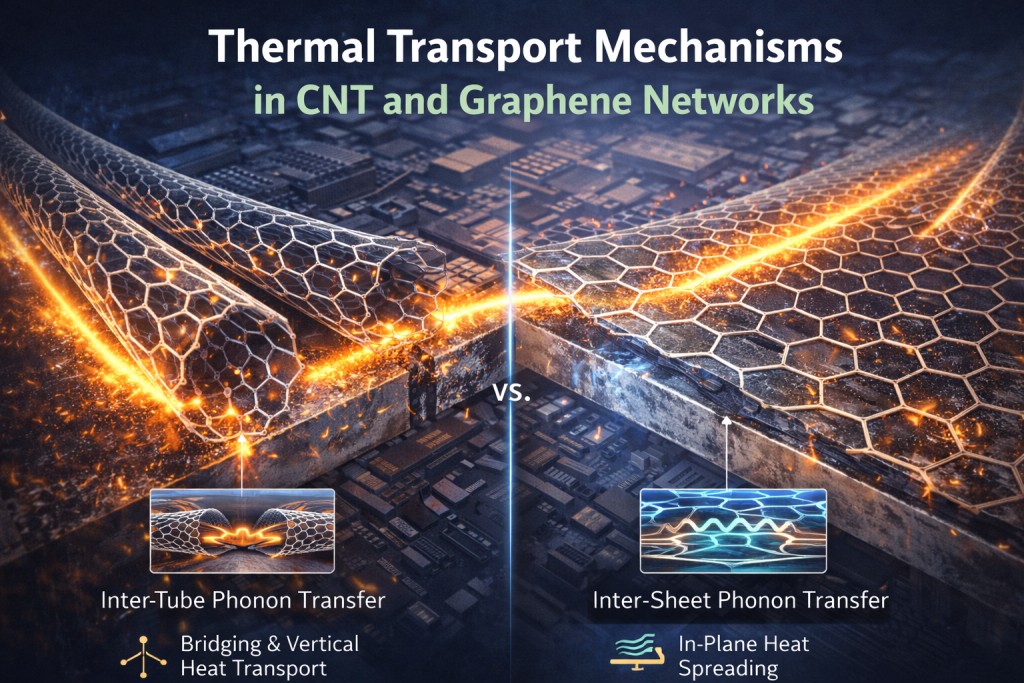

Thermal Transport Mechanisms in CNT and Graphene Networks

Understanding How Heat Really Moves at the Nanoscale

Beyond Thermal Conductivity Numbers

Carbon nanotubes (CNTs) and graphene are often introduced through their impressive intrinsic thermal conductivity values. However, real thermal performance in composites, films, and coatings is governed not by single-particle properties, but by network-level heat transport mechanisms.

Understanding how heat travels through CNT and graphene networks is essential for designing effective thermal materials—especially in thin, lightweight, and multifunctional systems.

Heat Transport at the Nanoscale: A Phonon Story

In CNTs and graphene, heat is primarily carried by phonons, which are quantized lattice vibrations.

Key characteristics:

-

Minimal phonon scattering along well-ordered carbon lattices

-

Extremely long phonon mean free paths

-

Direction-dependent heat transport behavior

Unlike metals, where electrons dominate heat transfer, phonon transport defines thermal performance in carbon nanomaterials.

Thermal Transport in Carbon Nanotube Networks

1. One-Dimensional Heat Conduction

CNTs act as one-dimensional thermal conductors, with heat flowing efficiently along the tube axis.

This enables:

-

Rapid heat transfer over long distances

-

Effective bridging between heat sources and sinks

-

Strong enhancement of through-plane thermal conductivity

However, axial conduction alone is not sufficient—inter-tube transport is equally critical.

2. Inter-Tube Thermal Resistance

When CNTs contact each other, heat must cross tube-to-tube junctions.

Challenges include:

-

Weak van der Waals contacts

-

Phonon mismatch between tubes

-

Contact resistance at junctions

As a result, network connectivity and contact quality often dominate overall thermal performance, more than individual CNT conductivity.

3. Role of Alignment and Network Density

Aligned CNT networks exhibit:

-

Higher directional thermal conductivity

-

Reduced phonon scattering

-

Improved thermal pathway continuity

Random networks rely on:

-

Higher CNT loading

-

Increased junction density

-

Optimized dispersion to minimize bottlenecks

Design choice depends on whether directional or isotropic heat transport is required.

Thermal Transport in Graphene Networks

1. Two-Dimensional In-Plane Heat Spreading

Graphene is a two-dimensional thermal conductor, excelling at in-plane heat transport.

Advantages include:

-

Exceptional lateral heat spreading

-

Uniform temperature distribution

-

Reduced hot spot formation

This makes graphene ideal for thermal coatings, films, and heat spreader layers.

2. Inter-Sheet Heat Transfer Challenges

In stacked graphene systems:

-

Heat must transfer across sheet interfaces

-

Interlayer thermal resistance becomes significant

-

Sheet orientation strongly affects performance

Poor alignment or excessive stacking can limit through-plane conductivity, even with high graphene loading.

3. Effect of Sheet Size and Layer Number

Thermal performance improves with:

-

Larger lateral sheet dimensions

-

Fewer defects

-

Controlled layer thickness

However, larger sheets increase dispersion difficulty, requiring careful formulation strategies.

CNT vs Graphene: Network Transport Comparison

| Aspect | CNT Networks | Graphene Networks |

|---|---|---|

| Dimensionality | 1D | 2D |

| Dominant Transport | Axial conduction | In-plane spreading |

| Key Limitation | Junction resistance | Interlayer resistance |

| Best Use Case | Bridging, through-plane | Surface heat spreading |

This fundamental difference explains why CNTs and graphene often complement rather than replace each other.

Hybrid CNT–Graphene Networks: Synergistic Transport

Hybrid systems combine:

-

CNTs as vertical or bridging connectors

-

Graphene sheets as lateral heat spreaders

Benefits include:

-

Reduced interfacial thermal resistance

-

Improved network continuity

-

Balanced in-plane and through-plane conductivity

Such hybrid architectures are increasingly used in advanced thermal interface materials and coatings.

Impact of Dispersion on Thermal Transport

Dispersion quality directly affects:

-

Network formation efficiency

-

Junction density and quality

-

Phonon scattering behavior

Poor dispersion leads to:

-

Agglomeration

-

Thermal dead zones

-

Inconsistent performance across the material

Effective dispersion strategies often matter more than increasing filler loading.

Interfacial Thermal Resistance with the Matrix

Even with a well-formed carbon network, heat must transfer between:

-

CNT/graphene and the polymer or binder

-

Adjacent layers in coatings or films

Surface functionalization, matrix selection, and processing conditions significantly influence carbon–matrix phonon coupling.

Thin Films and Coatings: Transport Under Confinement

In thin systems:

-

Boundary scattering becomes more pronounced

-

Orientation dominates transport behavior

-

Thickness constraints amplify interfacial effects

Graphene-based coatings often outperform CNT-only systems in ultra-thin layers due to superior in-plane transport.

Practical Design Implications

Effective thermal material design requires balancing:

-

Network architecture

-

Filler loading

-

Dispersion quality

-

Processing constraints

Optimized systems rarely use maximum filler content; instead, they focus on efficient thermal pathway design.

Testing Considerations: Avoiding Misleading Metrics

Thermal transport should be evaluated using:

-

Direction-specific measurements

-

Realistic thickness and interface conditions

-

Long-term thermal cycling tests

Bulk conductivity values alone do not predict real application performance.

Thermal Transport Is a Network Problem

Thermal transport in CNT and graphene systems is governed by how networks are formed, connected, and integrated, not just by intrinsic material properties.

-

CNTs enable directional heat transfer and interfacial bridging

-

Graphene enables efficient in-plane heat spreading

-

Hybrid networks unlock balanced thermal architectures

Understanding these mechanisms allows engineers to design lighter, thinner, and more efficient thermal solutions for next-generation systems.