Traditional Water Heating vs. Graphene Electric Floor Heating: A Cost Comparison

In the cold winter months, choosing the right heating method is crucial. Traditional water heating and graphene electric floor heating are two common options. But how do their usage costs compare?

1. Analyzing the Costs of Traditional Water Heating

Traditional water heating typically uses gas boilers or centralized heating as a heat source, with hot water circulating through pipes to provide warmth.

1)Energy Consumption:

Due to water’s high specific heat capacity, it can maintain temperature for extended periods, reducing energy consumption per unit of time. However, traditional systems have a thermal efficiency of around 70% to 75%, with slower heating speeds.

2)Operating Costs:

Energy prices vary by region, affecting overall operating costs. Heat loss in the pipe system can lead to some energy not fully transferring to the indoor space, increasing energy consumption and costs. Additionally, higher temperature settings or prolonged use can further raise energy costs.

3)Maintenance Costs:

Traditional water heating systems require regular maintenance, such as pipe cleaning, boiler inspections, and parts replacements, leading to variable expenses.

4)Depreciation:

Gas boilers typically have a lifespan of 7 to 10 years. Annual depreciation costs vary based on usage duration and equipment quality.

2. Examining the Costs of Graphene Electric Floor Heating

Graphene electric floor heating converts electrical energy into heat for warming spaces.

1)Energy Consumption:

The heating efficiency of graphene electric films can reach over 99.6%, significantly higher than traditional heating materials. These systems offer rapid heating and energy efficiency, making them ideal for applications that require high-efficiency heat conversion.

2)Operating Costs:

With precise temperature control, users can adjust indoor temperatures flexibly, saving energy. Specific costs vary depending on local electricity rates and usage habits.

3)Maintenance Costs:

Graphene electric floor heating has no maintenance costs post-installation.

4)Depreciation:

These systems have a long lifespan, often exceeding 50 years.

3. Key Factors Influencing Heating Costs

1)Insulation Quality:

Good insulation reduces heat loss, leading to energy savings. Upgrading homes with high-quality insulation materials can lower costs.

2)Usage Time and Temperature Settings:

Prolonged use at high temperatures inevitably increases energy consumption and costs. Reducing temperature settings when no one is home can save energy.

3)Energy Price Fluctuations:

Changes in energy prices directly affect costs and overall expenses.

In conclusion, selecting the most suitable heating method depends on a combination of factors, including energy prices, usage habits, and home insulation. As society advances, personalized heating solutions that are easy to control have become increasingly popular, with electric heating films leading the market. A study shows that metallic wire heating films, carbon fiber heating films, carbon crystal heating panels, and PTC ceramic heating films occupy 99% of the electric heating film market.

Among these, carbon-based heating films, particularly carbon fiber and carbon crystal heating films, dominate the market. However, carbon fiber heating films, while lightweight and flexible, have safety and longevity concerns. Carbon crystal heating films have also faced durability challenges. These issues indicate that the electric heating film industry in China has experienced an unprecedented bottleneck crisis in recent years.

The introduction and widespread use of graphene, known as the “black gold” and “king of new materials,” have broken through this bottleneck, allowing the industry to step confidently into the “graphene era.” Graphene electric heating films, composed purely of carbon atoms without any other materials, offer the highest safety and heat conversion efficiency among all electric heating elements.

Graphene, as a far-infrared heating element, boasts high heat conversion rates and ultra-fast heating speeds. With graphene electric heating films, floor heating systems can warm spaces instantly, improving comfort in daily life. The ultra-thin graphene far-infrared heating film has a thermal conversion rate of up to 99.6%, minimizing energy loss. Graphene-based floor heating, which uses far-infrared waves, is more aligned with the human body’s needs, ensuring efficient heat utilization.

By directly converting clean electrical energy into heat without producing waste gases, wastewater, noise, or electromagnetic radiation, graphene electric floor heating is a truly green and environmentally friendly heating solution. When combined with flooring, it creates a complete system that doesn’t take up additional space, is safe and waterproof, energy-efficient, and provides effective heating.

Furthermore, the electrical-to-heat conversion efficiency of graphene electric heating films approaches 100%, with almost no energy loss in the form of mechanical, light, or chemical energy. Compared to other electric heating components of the same power density, graphene electric heating films exhibit the highest efficiency in converting electrical energy to heat radiation. In essence, graphene heating films incorporate all the advantages of other electric heating components while avoiding many of their drawbacks.

Overall, graphene electric heating films offer excellent flexibility and stability, easy temperature control, strong waterproofing and corrosion resistance, high pressure tolerance, and are safe, eco-friendly, and non-flammable. These qualities make graphene electric heating films the future path of the electric heating industry.

Key Installation Steps for Graphene Floor Heating

1)Keep the Ground Level

Start by thoroughly cleaning the floor to remove debris such as small pits, holes, and stones. A level floor ensures the graphene floor heating film heats evenly.

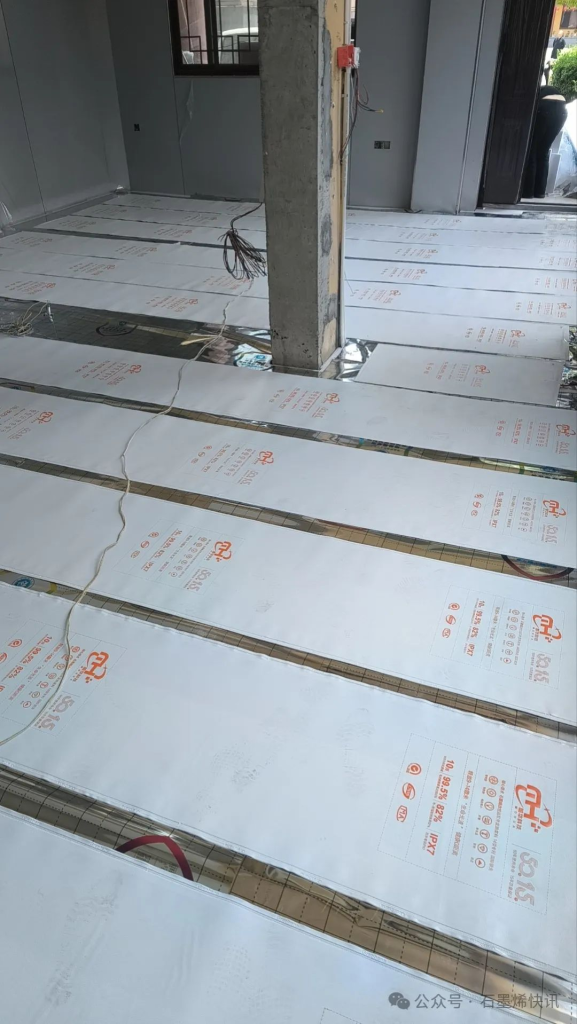

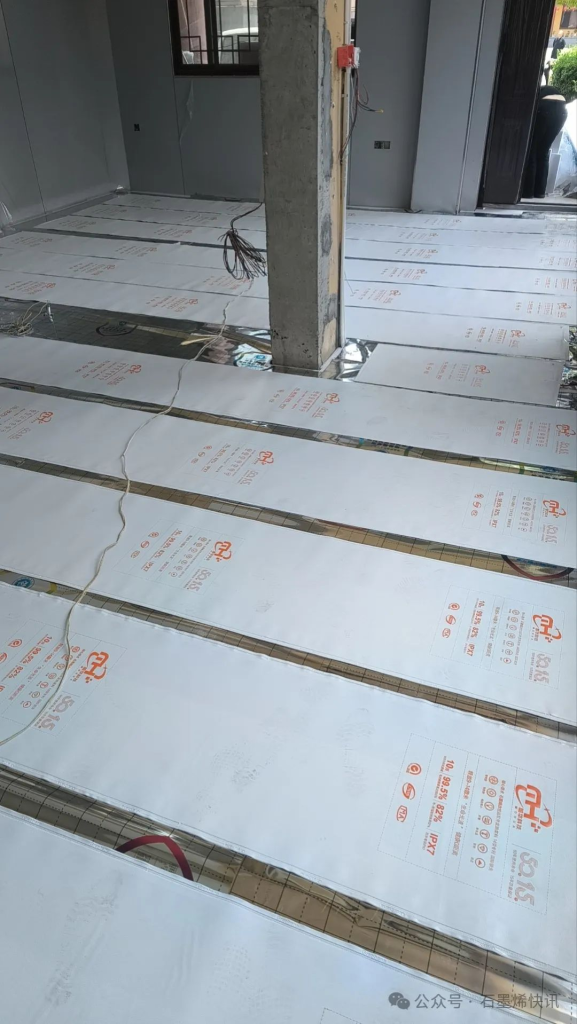

2)Install the Insulation Layer

Begin with the insulation layer, which prevents moisture, water, and mold while reducing the thickness of the building’s external structure. This increases the usable indoor space. Make sure the insulation boards are laid without any gaps to effectively protect the reflective and graphene heating films.

3)Lay Down a Reflective Film

Laying a reflective film prevents heat from escaping through the ground, improving heat reflection and radiation efficiency to maintain a consistent indoor temperature.

4)Install Graphene Electric Heating Film

Place the graphene electric heating film on top of the reflective film, following the pre-designed installation layout with the front side facing up. Connect the corresponding T-shaped wires to ensure proper electrical flow. The graphene encapsulation adds a protective layer to the original heating film, enhancing its waterproof, leak-proof, and anti-corrosion properties. This ensures the film remains intact even when embedded in cement for over 50 years, offering longer lifespan and improved safety.

5)Install the Thermostat

Connect the household power wires and the wires of the electric heating film to the thermostat, being careful not to mix up the neutral and live wires to avoid short circuits.

6)Conduct a Heating Test

Before laying flooring or tiles, slightly adjust the thermostat to check for any issues like short circuits or incorrect wiring.

7)Final Setup

Once the heating test is confirmed successful, proceed to lay down wood flooring or tiles. After this step, the system is ready for regular use.

Unlike traditional floor heating systems, which involve complex installations such as plumbing, electrical wiring, and water testing in kitchens and bathrooms, graphene floor heating simplifies the process. Traditional systems often require coordination with home design, wall finishing, and window installations, resulting in a lengthy process that can take several days or even weeks. The wait can be frustrating for many. In contrast, graphene floor heating is much simpler to install—two workers can complete, install, and test 100 square meters in just one day, making it a quick and convenient solution.