Understanding Graphene Dispersion – Stability, Solvents, and Surface Treatments

You can understand what graphene dispersion is, how stability is achieved, which solvents work best, and what surface modification techniques are used in this comprehensive beginner’s guide.

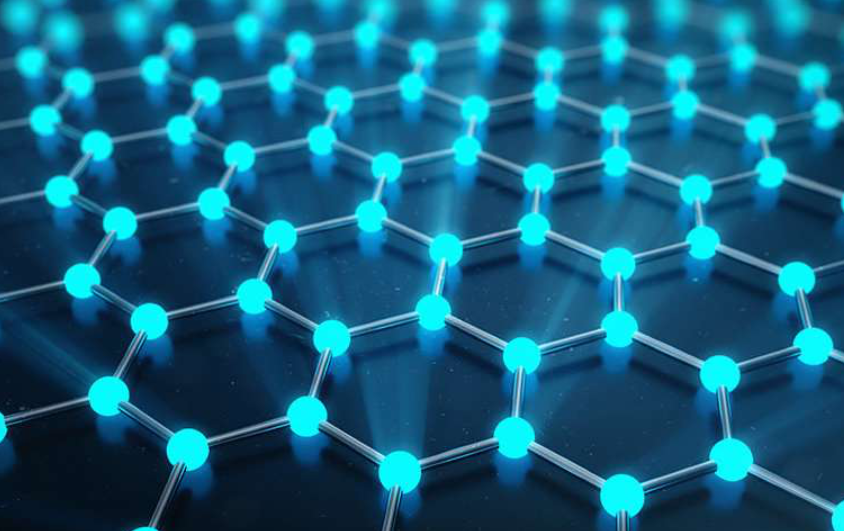

Graphene dispersion refers to the process of distributing graphene or graphene derivatives (like graphene oxide) evenly within a solvent, polymer, or resin system. Because graphene’s carbon atoms are tightly packed in a two-dimensional honeycomb lattice, the material tends to aggregate or restack due to strong π–π interactions and van der Waals forces.

A stable graphene dispersion is essential for manufacturing conductive inks, coatings, composites, and films. The key challenge lies in overcoming graphene’s natural tendency to clump together and ensuring uniform particle distribution over time.

Proper dispersion not only maintains graphene’s exceptional electrical and mechanical properties but also determines the performance of the final product.

Why Dispersion Matters

Without good dispersion, graphene loses:

-

Surface area → reduced active sites

-

Conductivity → poor electron transport

-

Mechanical reinforcement → weak interfacial bonding

-

Optical uniformity → uneven coatings or films

Hence, dispersion quality = material performance.

Types of Graphene Dispersions

1. Aqueous Graphene Dispersions

-

Graphene dispersed in water using surfactants or graphene oxide form.

-

Environmentally friendly and suitable for coatings, sensors, and water-based inks.

-

Typical stabilizers: SDS, Triton X-100, PVP.

2. Organic Solvent Dispersions

-

Solvents like NMP (N-Methyl-2-pyrrolidone), DMF (Dimethylformamide), and toluene provide better interaction with pristine graphene.

-

Suitable for high-performance electronic inks and conductive composites.

3. Polymer or Resin-Based Dispersions

-

Graphene is pre-mixed with thermoplastic or thermoset matrices (e.g., epoxy, PU, PMMA).

-

Ideal for structural composites, coatings, and adhesives.

4. Hybrid or Surfactant-Assisted Dispersions

-

Combine surfactants, binders, or ionic liquids for long-term stability.

-

Used in functional coatings and printed electronics.

Solvents Commonly Used for Graphene Dispersion

| Solvent | Type | Key Advantage | Typical Application |

|---|---|---|---|

| Water | Polar | Green, safe | Graphene oxide, coatings |

| NMP | Organic | High dispersion efficiency | Conductive inks |

| DMF | Organic | Good solvent for pristine graphene | Nanocomposites |

| Ethanol | Polar | Safe and easy to evaporate | Spray coatings |

| IPA | Semi-polar | Balanced drying and compatibility | Printing and coating |

| Toluene | Nonpolar | Hydrophobic graphene dispersion | Epoxy systems |

The best solvent depends on graphene type (GO, rGO, pristine) and target application.

Surface Modification & Functionalization

To enhance stability and prevent re-agglomeration, graphene can be modified by:

1. Covalent Functionalization

Attaching chemical groups such as –COOH, –OH, or –NH₂ on graphene’s surface.

-

Improves bonding with polymers and resins.

-

Enables water dispersibility.

2. Non-Covalent Functionalization

Uses π–π stacking or surfactants to stabilize graphene in solvents.

-

Maintains electrical conductivity.

-

Ideal for electronic applications.

3. Polymer Wrapping

Polymers like PVP, PEG, or polyaniline can physically coat graphene flakes.

-

Enhances dispersion in both aqueous and organic systems.

Dispersion Techniques

-

Ultrasonication: Breaks agglomerates through sound waves.

-

High-Shear Mixing: Mechanical force distributes graphene evenly.

-

Ball Milling: Suitable for large-scale dispersion (not for electronic-grade materials).

-

Three-Roll Milling: Achieves fine and uniform graphene distribution in viscous matrices.

What Should I Consider When Buying Graphene Dispersion?

-

Type: Aqueous or solvent-based?

-

Concentration: Usually 0.5–10 wt%.

-

Flake Size: 0.5–20 µm affects film smoothness.

-

Purity: Check for metal-free certification.

-

Stability: Shelf life and sedimentation rate.

-

Compatibility: Match solvent type to your target resin or coating system.

-

Cost (2025): $80–$300 per liter depending on concentration and purity.

How to Use Graphene Dispersion

Step 1. Gently stir or shake before use.

Step 2. If required, ultrasonicate for 10–30 minutes.

Step 3. Mix into resin or ink under controlled shear conditions.

Step 4. Apply by spraying, printing, or dip-coating.

Step 5. Dry at low temperatures to avoid oxidation or reduction.

Step 6. Seal container tightly after use.

Top Graphene Dispersions in 2025

#1 AquaGraph™ (Water-Based Graphene Dispersion)

-

Concentration: 5 wt%

-

Stable for 12+ months

-

Ideal for coatings and conductive inks

#2 NMP-GD™ (Graphene in NMP Solvent)

-

Conductivity: >10³ S/m

-

For printed electronics

#3 Graphene MasterDisp™

-

Polymer pre-dispersed system (Epoxy or PU)

-

Ready to mix directly into composites

Understanding graphene dispersion is crucial for achieving consistent performance, strong bonding, and long-term stability in any graphene-based application. Whether you’re formulating conductive inks or polymer composites, mastering dispersion techniques and solvent selection is the foundation of successful graphene processing.

After reading this guide, are you ready to create your perfectly dispersed graphene system?