🧭 Introduction: Why ESD Matters

Electrostatic discharge (ESD) may seem trivial — just a tiny spark — but in industrial environments and electronics manufacturing, it can be catastrophic. A single micro-discharge can permanently damage sensitive electronic components, disrupt sensors, ignite flammable materials, or cause dangerous system malfunctions.

Traditionally, ESD control involves grounded workstations, ionizers, and antistatic coatings. Among these, the coating approach is particularly valuable because it protects large surfaces and moving parts. However, many conventional antistatic coatings are either solvent-based, toxic, short-lived, or simply insufficient in conductivity. That’s where graphene-based waterborne coatings step in as a safer, more effective alternative.

⚙️ Section 1: The Limitations of Traditional Antistatic Agents

Traditional antistatic agents include:

-

Carbon black: Low-cost but requires high loadings and causes black coloration and brittleness.

-

Metal particles: High conductivity but prone to oxidation and expensive.

-

Conductive polymers: Such as PEDOT:PSS, which are effective but sensitive to humidity and UV.

-

Quaternary ammonium salts: Common in surface sprays but only offer temporary antistatic performance.

Each comes with trade-offs: color contamination, toxicity, short lifespan, or limited compatibility with flexible substrates like plastic films or textiles.

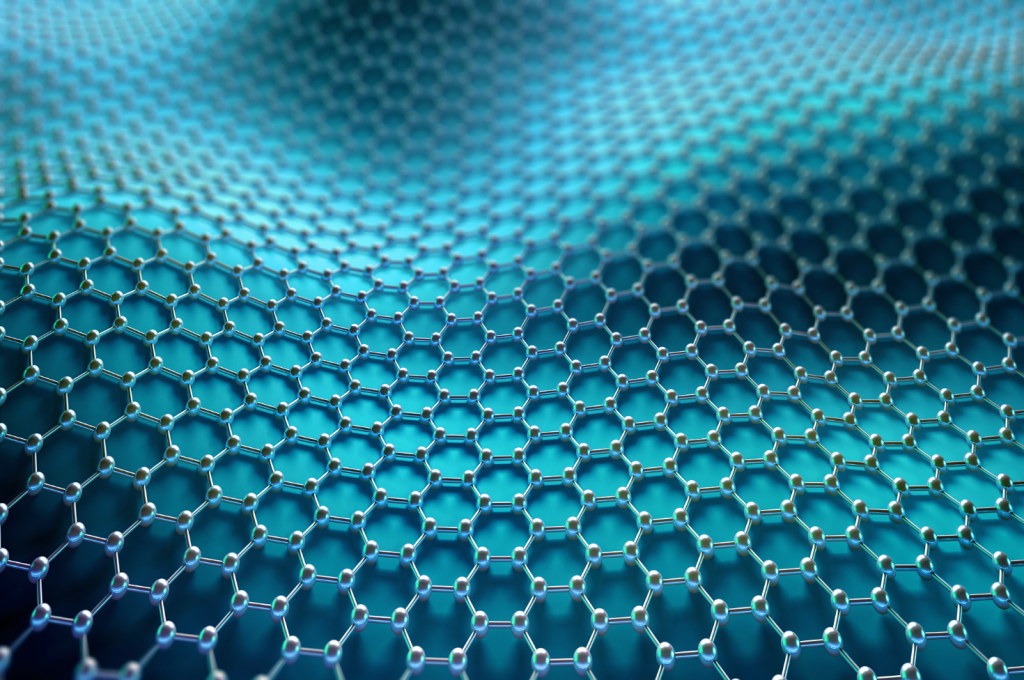

🌌 Section 2: Why Graphene Offers a Better Solution

Graphene — specifically reduced graphene oxide (RGO) — is gaining rapid adoption as a new class of permanent, low-dosage antistatic additive, especially in water-based coating systems.

Key Properties:

-

High electrical conductivity even at loadings <1 wt%

-

Two-dimensional (2D) structure for excellent surface contact

-

Chemically stable across pH range and environmental conditions

-

Lightweight and invisible in thin films

-

Compatible with common resin systems (PU, acrylic, epoxy, latex)

By dispersing graphene uniformly within a coating matrix, one can create interconnected conductive networks that allow electrons to move and dissipate surface charges effectively.

🧪 Section 3: How It Works – The Science Behind It

The conductivity of an antistatic coating depends on percolation threshold — the minimum filler concentration needed to create a continuous conductive path.

Graphene has an extremely high aspect ratio (~1000:1 or more), meaning it spreads out efficiently across a surface. This allows it to achieve percolation at loadings as low as 0.3–0.8 wt%, significantly lower than other fillers like carbon black (which often needs >5%).

Once cured, the thin coating forms a robust mesh of RGO flakes, absorbing, distributing, and neutralizing static charges as they build up — all without needing direct grounding or expensive ionizing systems.

🔬 Section 4: Performance Metrics (Lab & Industrial)

At GrapheneRich, we’ve tested our GR-RGO water dispersion across a range of common coating systems.

Example Test Results:

| Property | Result (with 0.6% GR-RGO) | Benchmark |

|---|---|---|

| Surface resistivity | ~10⁷ Ω/sq | Meets ESD safe threshold |

| Film transparency | ~88% @ 1 µm thickness | Nearly invisible |

| Adhesion (cross hatch) | 4B–5B on PU, acrylic, epoxy | Excellent |

| Humidity resistance | 1000 h @ 85% RH, no change | Stable |

| Abrasion resistance | >1000 cycles (Taber) | Pass |

These properties are suitable for flexible packaging, ESD trays, floors, cleanroom surfaces, smart textiles, and more.

🏭 Section 5: Use Cases in Real-World Industry

💼 1. Flexible Electronics

For touchscreen modules, displays, and sensors, traditional antistatic sprays are too temporary. Graphene-based PU coatings offer permanent, transparent ESD protection — ideal for OLED or printed electronics.

📦 2. Packaging Films and Trays

Graphene dispersions can be applied to stretch films or molded into plastic trays. Result: permanent antistatic trays that won’t degrade in dry conditions like some polymers do.

🧴 3. Spray Coatings for Tools & Equipment

Using sprayable acrylic + graphene dispersions, maintenance teams can easily coat work surfaces, casings, or tooling in manufacturing lines.

👚 4. Antistatic Textiles

Waterborne graphene formulations can be used as dip or roll coatings on polyester and nylon. Textiles retain breathability and flexibility while becoming ESD-safe.

🧩 Section 6: Product Spotlight – GR-RGO Water Dispersion

Our in-house developed GR-RGO product is designed for formulators needing stable, efficient water-based graphene.

Product Features:

-

Concentration: 0.5–5 mg/mL (customizable)

-

Particle Size: <5 µm (D90) for easy integration into coatings

-

Dispersant: XFZ20 non-toxic, compatible with most resin systems

-

Appearance: Dark grey/black suspension

-

Stability: >30 days shelf life under sealed conditions

Recommended Use:

-

Add directly into water-based resins (PU, epoxy, acrylic)

-

Stir or homogenize at 800–1000 rpm for 5–10 mins

-

Apply via spray, brush, roll or dip

-

Dry at room temperature or 60–100°C depending on resin type

📩 Request a sample or full technical data sheet via graphenerich.com/contact

❓ Section 7: Frequently Asked Questions

Q1: Does graphene replace conductive polymers like PEDOT:PSS?

Not entirely. PEDOT is excellent for transparency, but not stable under long-term UV or moisture. Graphene-RGO coatings are more rugged and chemically stable, and can be used together with PEDOT in hybrid systems.

Q2: Is your graphene safe to handle in manufacturing?

Yes. Our aqueous dispersion is free of solvents and heavy metals, and complies with RoHS and REACH for industrial use.

Q3: Can this be used in food-contact packaging?

Our product is not certified for direct food contact yet, but we’re happy to support third-party testing if required.

Q4: Will it change the color of my transparent coating?

At <0.5 wt%, the coating will appear lightly grayish or invisible. Higher loading may cause slight darkening — we can recommend levels based on your desired transparency.

✅ Conclusion: Graphene is the Future of Safe, Waterborne ESD Coatings

In today’s world of electronics, cleanrooms, and smart materials, controlling static safely and sustainably is no longer optional. Graphene offers a new standard — effective at low loading, friendly to waterborne systems, and chemically robust for industrial-scale use.

If you are a formulator, OEM, or device engineer looking for an eco-friendly, high-performance antistatic solution, it’s time to explore how graphene can upgrade your product line.