Unlocking the Potential of Graphene: Costs, Benefits, and Business Applications

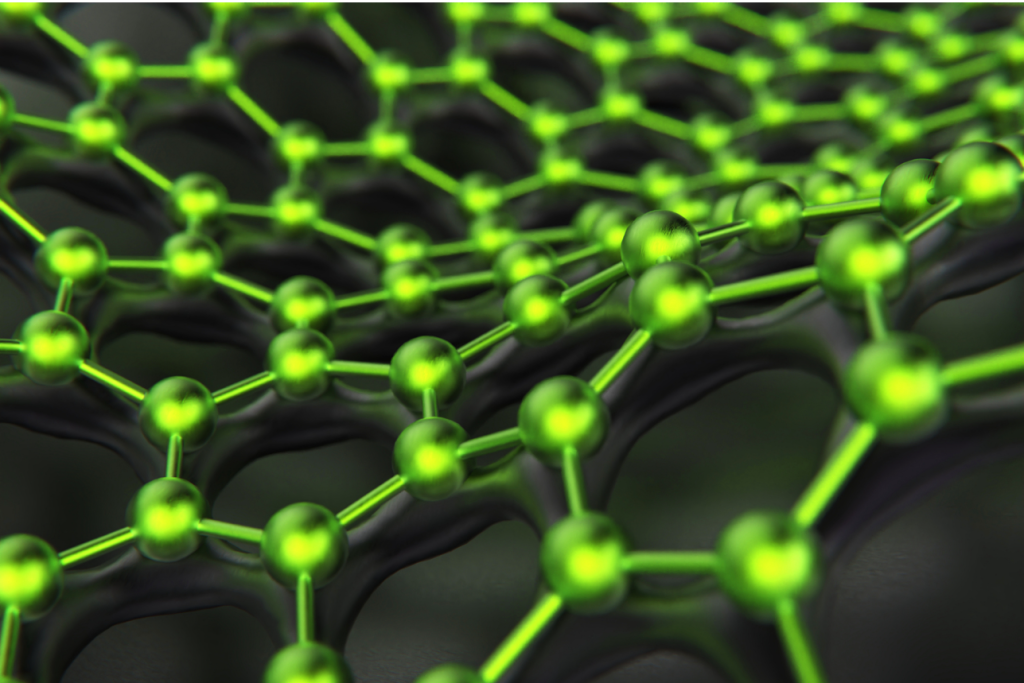

If you’ve ever wondered about the commercial potential of graphene, you’re not alone. As a revolutionary nanomaterial with exceptional mechanical, electrical, and thermal properties, graphene has captured the attention of industries worldwide. But is it worth investing in graphene-based materials for your business? Does graphene offer a return on investment that justifies its cost? Let’s explore the value proposition of graphene and whether it’s a game-changer for various industries.

Is Investing in Graphene Worth It in 2025?

Graphene is a versatile material that benefits industries ranging from electronics to construction. Businesses looking to leverage cutting-edge materials can explore graphene to enhance product performance and gain a competitive edge. However, the costs, applications, and return on investment (ROI) should be carefully analyzed before committing to large-scale adoption.

Cost vs. Value: The Debate

Graphene production costs vary significantly depending on the synthesis method and purity level. High-quality monolayer graphene produced via chemical vapor deposition (CVD) can be expensive, while graphene nanoplatelets and graphene oxide offer more cost-effective alternatives. While initial investment in graphene-based materials may be high, their long-term benefits in terms of durability, conductivity, and weight reduction can outweigh the cost.

Profit Potential for Business Owners

Businesses can capitalize on graphene’s unique properties to create high-value products. Industries such as coatings, plastics, energy storage, and electronics are already incorporating graphene into their products for enhanced performance. Graphene-based coatings improve corrosion resistance, while graphene-enhanced polymers offer superior strength and flexibility. Companies leveraging these advantages can establish themselves as pioneers in their respective fields, attracting premium pricing and market differentiation.

Graphene for Innovators: Revolutionary or Overhyped?

The potential applications of graphene are vast, but is it truly the ‘wonder material’ it’s often claimed to be? While research continues to uncover new possibilities, some challenges remain—such as large-scale production, consistency in quality, and regulatory approvals. Businesses must assess whether they have the infrastructure and expertise to integrate graphene effectively into their supply chain.

Ease of Use and Learning Curve

Incorporating graphene into existing products requires a solid understanding of dispersion methods, compatibility with different materials, and manufacturing processes. While industries like coatings and composites have made strides in adopting graphene, others may require significant R&D investment to unlock its full potential. Companies must be prepared for a learning curve and potential trial-and-error phases before realizing graphene’s benefits.

Maintenance and Longevity

Graphene-based materials often enhance product lifespan by improving resistance to wear, heat, and corrosion. However, ensuring proper integration into manufacturing processes is essential for long-term durability. Businesses investing in graphene should also consider supplier reliability and material consistency to maintain product quality over time.

Who Should Invest in Graphene? Industry Breakdown

Graphene’s applications span multiple industries, but which sectors stand to gain the most?

Electronics and Energy Storage

Graphene’s high conductivity and flexibility make it ideal for next-generation batteries, supercapacitors, and flexible electronics. Companies in the energy and tech sectors can benefit from graphene-enhanced components that offer improved efficiency and durability.

Coatings and Paints

Graphene-based coatings provide superior resistance to corrosion, water, and chemicals. This makes it an attractive investment for the automotive, aerospace, and marine industries seeking to enhance longevity and reduce maintenance costs.

Plastics and Composites

Graphene can reinforce plastics, making them stronger, lighter, and more heat-resistant. Industries such as packaging, construction, and consumer goods can use graphene-enhanced composites for superior product performance.

Textiles and Wearables

Graphene-infused fabrics can offer antibacterial properties, thermal regulation, and enhanced durability. This makes it a promising material for high-performance sportswear and medical textiles.

ROI of Graphene for Small Businesses

Is graphene a viable investment for small businesses? The answer depends on the application and market demand. Businesses that rely on high-performance materials, such as niche coatings, conductive inks, or advanced composites, can justify the cost through premium pricing. However, small-scale manufacturers must weigh the costs of R&D and production before integrating graphene into their products.

Initial Investment vs. Long-Term Gains

While graphene may require a higher initial investment, the cost savings in material efficiency, product lifespan, and enhanced performance can lead to long-term financial benefits. Companies focusing on innovation and differentiation can leverage graphene for a sustainable competitive advantage.

High-Profit Margins on Graphene-Based Products

Graphene-enhanced products command higher prices due to their improved properties. For example, graphene-coated batteries can charge faster and last longer, making them attractive for premium markets. Similarly, graphene-reinforced plastics and composites offer superior strength-to-weight ratios, allowing manufacturers to create lightweight, high-performance products.

Diverse Revenue Streams and Market Expansion

By incorporating graphene, businesses can tap into emerging industries such as smart textiles, flexible electronics, and next-generation energy solutions. Expanding into these markets can diversify revenue streams and mitigate risks associated with traditional materials.

Industrial vs. Small-Scale Graphene Use: Which One Suits You?

The scale of graphene application depends on your business needs. Large industries investing in mass production can benefit from economies of scale, while smaller companies can target niche markets where graphene offers a unique selling point.

Bulk Manufacturing vs. Customization

Large-scale manufacturers can integrate graphene into mass production, reducing per-unit costs over time. On the other hand, small businesses can use graphene for specialized, high-value applications, such as custom coatings or high-performance textiles.

Material Compatibility and Processing Challenges

Graphene must be properly dispersed and processed to deliver its full potential. Companies investing in graphene must ensure they have the right technical expertise and equipment to integrate it effectively into their production lines.

Future Outlook: Is Graphene the Next Industrial Revolution?

Graphene’s commercial adoption is still in its early stages, but ongoing advancements in production techniques are making it more accessible. As costs decrease and scalability improves, graphene will likely become a staple in various industries.

Final Thoughts

So, is graphene worth the investment? If your business operates in a sector that values lightweight strength, superior conductivity, or advanced coatings, graphene could be a game-changer. The key is to assess your specific needs, understand the integration challenges, and weigh the cost-benefit ratio. For high-tech industries, graphene presents significant opportunities, but for occasional or low-budget applications, traditional materials may still suffice.

For those ready to embrace innovation, graphene offers exciting possibilities. Companies that strategically invest in graphene today could position themselves at the forefront of the next material revolution, reaping substantial rewards in the years to come.