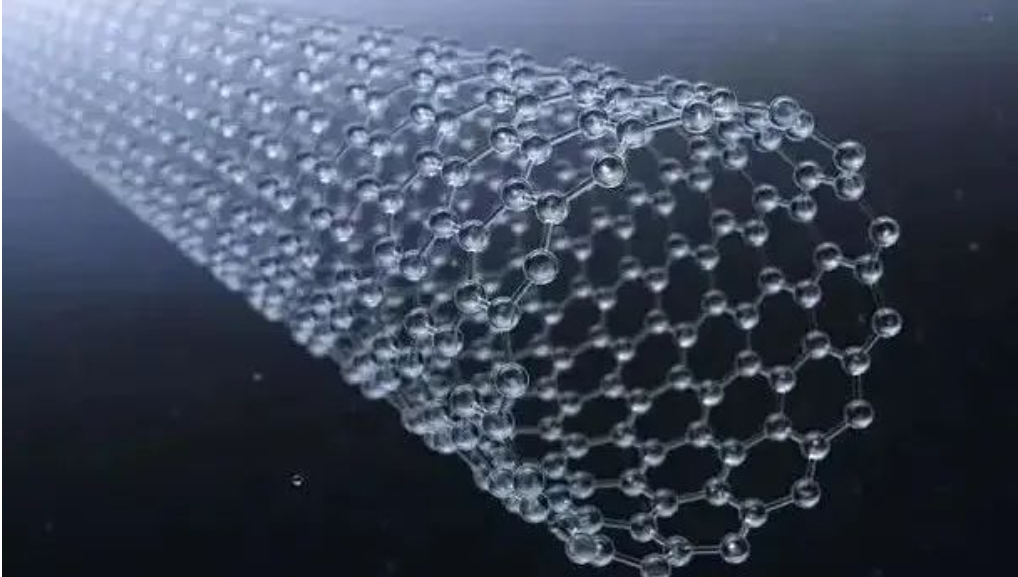

Why Are Carbon Nanotubes (CNTs) So Important in Lithium-Ion Batteries? What Are Their Functions?

Carbon nanotubes (CNTs) play a crucial role in lithium-ion batteries, primarily in the following aspects:

1. High Electrical Conductivity

-

Explanation: CNTs exhibit extremely high electrical conductivity (~10⁶ S/m), significantly enhancing electron transport efficiency in electrode materials. This reduces internal resistance and improves battery charge and discharge performance. The three-dimensional conductive network formed by CNTs effectively connects active material particles, enhancing the overall conductivity of the electrode.

-

Data: Research indicates that adding 1–2 wt% of CNTs can increase the electrode’s conductivity by more than 50%.

-

Comparison: Compared to carbon black (~10² S/m), CNTs reduce electrode internal resistance by approximately 30–50% at the same loading, significantly improving battery rate performance.

2. High Mechanical Strength

-

Explanation: CNTs have an extremely high tensile strength (50–200 GPa), over 100 times that of steel. This strength helps mitigate volume expansion and contraction of electrode materials during charge and discharge cycles, enhancing structural stability.

-

Data: In silicon-based anodes, adding 5 wt% CNTs can extend cycle life from 100 to over 500 cycles.

-

Comparison: Compared to graphene, CNTs offer superior mechanical strength, particularly in suppressing volume expansion in silicon-based materials.

3. High Specific Surface Area

-

Explanation: CNTs possess a large specific surface area (100–1300 m²/g), providing more active sites for lithium-ion adsorption and desorption, thereby enhancing battery capacity and rate performance.

-

Data: In supercapacitors, CNT-based electrodes can achieve specific capacitances of 100–200 F/g.

-

Comparison: Compared to activated carbon, CNT electrodes improve electrochemical performance by approximately 20–30% at the same specific surface area.

4. Excellent Thermal Conductivity

-

Explanation: CNTs have a thermal conductivity of 3000–6000 W/mK, more than ten times that of copper. This excellent thermal conductivity facilitates rapid heat dissipation within the battery, improving thermal management and enhancing safety.

-

Data: Adding 1 wt% CNTs to battery electrodes can increase thermal conductivity by approximately 50%.

-

Comparison: Compared to graphene, CNTs demonstrate superior thermal conductivity, especially in high-temperature environments, with better thermal stability.

5. Flexibility

-

Explanation: CNTs exhibit excellent flexibility and mechanical strength, making them suitable for flexible battery designs used in wearable electronics. Flexible batteries require electrode materials to maintain good electrochemical performance under bending and stretching conditions.

-

Data: CNT-based flexible electrodes retain over 90% of their electrochemical performance at a bending radius of less than 5 mm. Even after 1000 bending cycles, capacity retention exceeds 85%.

-

Comparison: Compared to traditional metal foil electrodes, CNT-based flexible electrodes offer significant advantages in mechanical flexibility and electrochemical performance.

6. Nanoscale Dimensions

-

Explanation: CNTs typically have diameters ranging from 1–100 nm and lengths extending to several micrometers. These nanoscale properties help shorten lithium-ion diffusion paths, enhance ion migration rates, and improve power density and fast-charging capability.

-

Data: In fast-charging battery designs, CNTs effectively reduce electrode polarization and enhance rapid charging performance.

-

Comparison: Compared to micron-scale conductive additives, CNTs improve battery power density by approximately 20–40% at the same loading.

7. Multifunctional Additive

-

Explanation: CNTs serve as conductive additives that can replace traditional carbon black materials. With lower required loading, CNTs achieve better conductivity. Additionally, CNTs form a three-dimensional conductive network that significantly enhances overall electrode conductivity.

-

Data: Adding 1 wt% CNTs can improve electrode conductivity by approximately 50%.

-

Comparison: Compared to carbon black, CNTs reduce the required additive amount by about 80% for the same conductivity, lowering electrode weight and cost.

8. Composite Electrode Materials

-

Explanation: CNTs can be combined with various active materials (such as silicon, sulfur, and metal oxides) to create high-performance composite electrodes. These composites not only offer high conductivity but also effectively suppress volume expansion of active materials, improving electrode structural stability.

-

Data: CNT-silicon composites extend electrode cycle life from 100 to over 500 cycles, with a capacity retention rate exceeding 80%. In lithium-sulfur batteries, CNT composite electrodes achieve specific capacities of up to 1200 mAh/g.

-

Comparison: Compared to traditional graphite anodes, CNT-silicon composite anodes increase energy density by approximately 30–50%.

9. Promoting Uniform Deposition

-

Explanation: In lithium-metal batteries, CNTs guide lithium-ion deposition, preventing dendrite growth. Lithium dendrites pose a major safety risk as they can pierce the separator, leading to short circuits or even fires and explosions.

-

Data: CNT-based substrates can increase dendrite suppression rates to over 90%, extending cycle life from 50 to over 200 cycles.

-

Comparison: Compared to traditional copper foil substrates, CNT-based substrates offer superior lithium deposition uniformity and safety.

10. Environmental Friendliness

-

Explanation: The use of CNTs reduces the amount of other materials needed in batteries, minimizing environmental impact. Additionally, CNTs exhibit high chemical stability and do not easily degrade, aiding in the development of more sustainable battery technologies.

-

Data: The incorporation of CNTs reduces the required amount of other battery materials by approximately 20–30%, lowering carbon emissions during production by about 30% compared to conventional materials.

-

Comparison: Compared to traditional conductive additives, CNTs demonstrate superior environmental friendliness and sustainability.

Conclusion

The application of CNTs in lithium-ion batteries extends beyond a single function. Their unique physical and chemical properties contribute significantly to improving conductivity, mechanical strength, thermal management, flexibility, and more. As battery technology continues to evolve, CNTs will play an even greater role in enhancing performance, safety, and environmental sustainability, driving the development and application of next-generation high-performance batteries.