Why is Graphene So Revolutionary?

Graphene, often referred to as the “wonder material,” is not just a scientific marvel but a game-changer across various industries. Despite its incredible potential, its adoption comes at a significant cost—both financially and technically. In this article, we will explore what makes graphene so revolutionary, its applications, and the reasons behind its high production and adoption costs. If you’ve been curious about why graphene is considered a groundbreaking material, keep reading.

Applications of Graphene

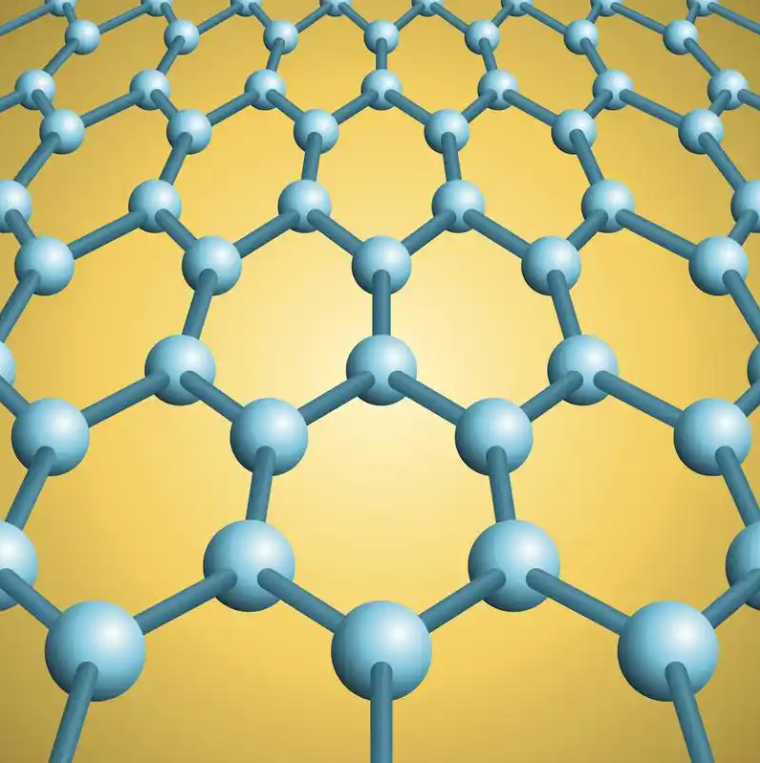

Graphene is a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice. Its exceptional properties, including high electrical conductivity, mechanical strength, and thermal conductivity, have led to groundbreaking applications in various fields. Below are some of the industries where graphene has made its mark:

- Electronics: Used in high-speed transistors, flexible screens, and next-generation semiconductors.

- Energy Storage: Found in supercapacitors and batteries for faster charging and longer life.

- Aerospace: Enhances strength while reducing the weight of composite materials.

- Healthcare: Integrated into drug delivery systems, biosensors, and medical imaging.

- Water Filtration: Serves as an effective material for desalination and water purification membranes.

- Construction: Acts as an additive in cement and concrete to improve durability and reduce carbon emissions.

Graphene’s potential is virtually limitless, making it one of the most researched materials in modern science and engineering.

Why is Graphene Expensive?

Graphene is considered one of the most revolutionary materials of the 21st century, but it comes at a significant cost. This high expense is due to the complexities involved in its production and the need for specialized technology and infrastructure. Below are some key reasons why graphene remains a costly material:

Production Challenges

Producing high-quality graphene is not straightforward. There are several methods, including chemical vapor deposition (CVD), mechanical exfoliation, and chemical reduction of graphene oxide. Among these, CVD produces the highest quality graphene but involves expensive equipment and time-intensive processes. Scaling these methods for industrial production remains a significant hurdle.

Purity and Quality

The quality of graphene greatly influences its usability. High-purity graphene sheets are essential for applications in electronics and energy storage. Achieving this level of purity often involves meticulous production methods, leading to higher costs.

Customization and Functionalization

Many applications require graphene to be tailored for specific uses. Functionalization, such as adding chemical groups or modifying its structure, increases both its versatility and cost.

Research and Development

Graphene is still in its early stages of widespread adoption. Significant investments in research and development are necessary to discover new applications, optimize production processes, and address scalability challenges.

Lack of Standardization

Unlike traditional materials, graphene lacks standardized production methods and quality benchmarks. This variability adds to the cost as manufacturers work to meet the specific requirements of various industries.

Average Cost of Graphene

The cost of graphene varies significantly based on its form, purity, and production method. Below is an overview of the average costs:

| Type of Graphene | Cost Range (per gram) |

|---|---|

| Graphene Powder | $100 – $500 |

| Graphene Oxide | $50 – $200 |

| Single-Layer CVD Graphene | $50 – $1,000 |

| Reduced Graphene Oxide | $30 – $150 |

While these costs may seem prohibitive, advancements in production technology are expected to bring prices down over time, making graphene more accessible for commercial applications.

Total Cost of Ownership (TCO)

Investing in graphene involves more than just the initial purchase price. The total cost of ownership (TCO) includes factors like:

- Raw Material Costs: Sourcing high-quality graphite or precursors.

- Processing Costs: Energy-intensive and technologically demanding production methods.

- Equipment Maintenance: Upkeep of specialized machinery for production.

- Training and Skill Development: Educating staff to handle and integrate graphene into products.

- Research Investments: Continued innovation to enhance efficiency and discover new applications.

Cost-Affecting Factors

Several factors contribute to the high cost of graphene. Understanding these can help industries make informed decisions when considering its use.

Method of Production

Different production methods yield varying qualities and quantities of graphene. High-quality single-layer graphene produced via CVD is significantly more expensive than graphene oxide or reduced graphene oxide.

Purity and Layer Control

Applications like electronics demand single-layer graphene with minimal defects, whereas other industries may tolerate multi-layer graphene. The precision required to control these parameters impacts cost.

Scale of Production

Graphene is challenging to scale due to its complex production methods. Bulk production often sacrifices quality, while maintaining quality increases costs.

Application-Specific Requirements

Industries like aerospace or healthcare often require graphene to meet stringent specifications. Customizing graphene for such applications adds to its cost.

Brand Reputation and Support

Leading graphene producers often charge a premium due to their reputation for quality, reliability, and customer support. Established brands also invest heavily in R&D, which reflects in their pricing.

Types of Graphene Products

Graphene is available in various forms, each tailored for specific applications:

- Graphene Powder: Used in composites and coatings.

- Graphene Oxide: Ideal for energy storage and water filtration.

- Reduced Graphene Oxide: Popular in conductive inks and paints.

- Single-Layer Graphene Sheets: Essential for electronics and high-end applications.

- Graphene Films: Applied in sensors and flexible displays.

How to Reduce Costs

Reducing the cost of graphene requires innovation at multiple levels. Here are some strategies to make graphene more affordable:

- Optimize Production Methods: Focus on improving yield and reducing waste.

- Scale-Up Infrastructure: Develop facilities for large-scale production without compromising quality.

- Invest in Automation: Automate production processes to reduce labor costs.

- Enhance Material Efficiency: Develop techniques to use graphene more effectively in smaller quantities.

- Encourage Collaboration: Foster partnerships between academia, industry, and government to share knowledge and reduce R&D costs.

- Standardize Processes: Establish industry standards to streamline production and reduce variability.

Final Words

Graphene holds immense potential to transform industries ranging from electronics to healthcare. However, its high cost remains a barrier to widespread adoption. By understanding the factors that drive up costs and working on innovative solutions to reduce them, we can unlock the full potential of this wonder material. As research advances and production scales improve, graphene’s revolutionary impact is likely to become more accessible, paving the way for a future shaped by its extraordinary capabilities.