Carbon Nanotube-Graphene Fibers for Thermal Management Applications

Wearable textiles for thermal management require phase-change fibers that can store and release heat efficiently while responding to various environmental stimuli. However, producing phase-change fibers with a balanced combination of properties—especially adequate thermal conductivity—remains a significant challenge.

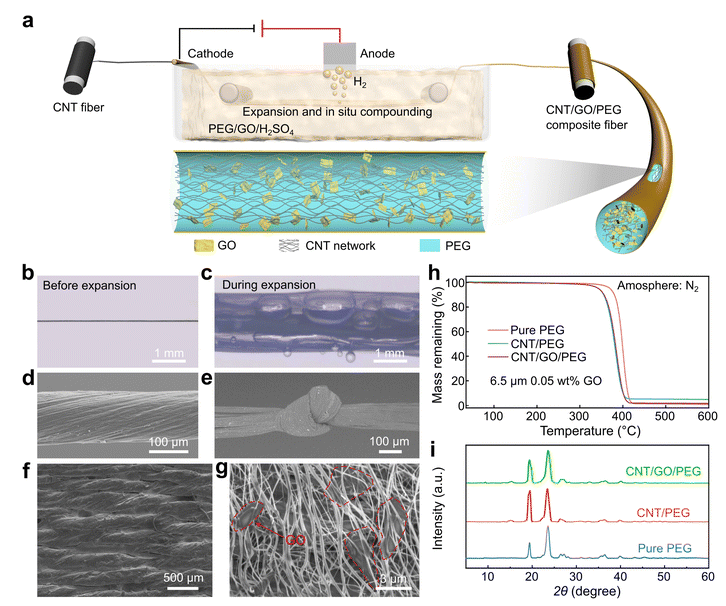

A recent study, published in the Journal of Materials Chemistry C by Jingna Zhao from the Suzhou Institute of Nano-Tech and Nano-Bionics, Chinese Academy of Sciences, and Xiaohua Zhang from Donghua University, introduces a novel solution. Titled “Carbon nanotube graphene multilevel network-based phase change fibers and their energy storage properties,” the research explores an innovative in-situ impregnation strategy. This approach integrates graphene oxide (GO) and polyethylene glycol (PEG) into a carbon nanotube (CNT) network, forming a hierarchical 1D-2D structure that enhances fiber performance.

Key Features of CNT/GO/PEG Composite Phase-Change Fibers

- Enhanced Interfacial Contact and Volume Capacity

- GO improves interfacial interactions within the fiber structure and optimizes space utilization.

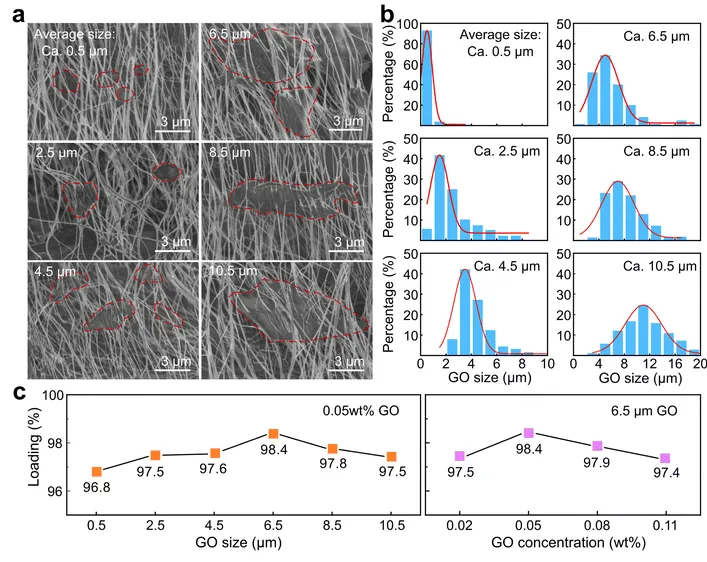

- The composite achieves PEG loadings up to 96.8%-98.4%, ensuring high energy storage efficiency.

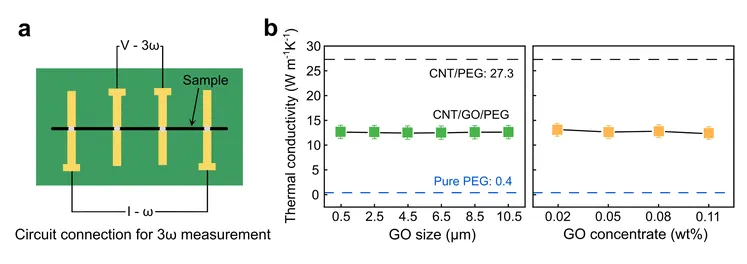

- Optimized Thermal Conductivity

- The CNT/GO/PEG fibers exhibit a relatively low thermal conductivity range of 12.5–13.5 W m⁻¹ K⁻¹, balancing heat transfer and insulation.

- GO’s hierarchical network contributes to both thermal regulation and reduced heat loss.

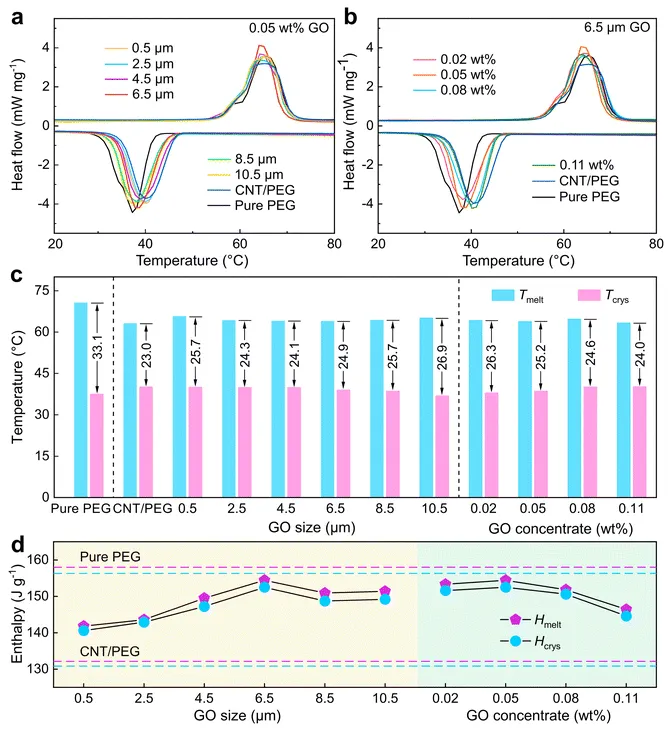

- Efficient Heat Management

- The high PEG loading ensures higher thermal efficiency during heat release and supports stable phase-change behavior.

- Improved photothermal efficiency makes these fibers ideal for applications such as thermal textiles.

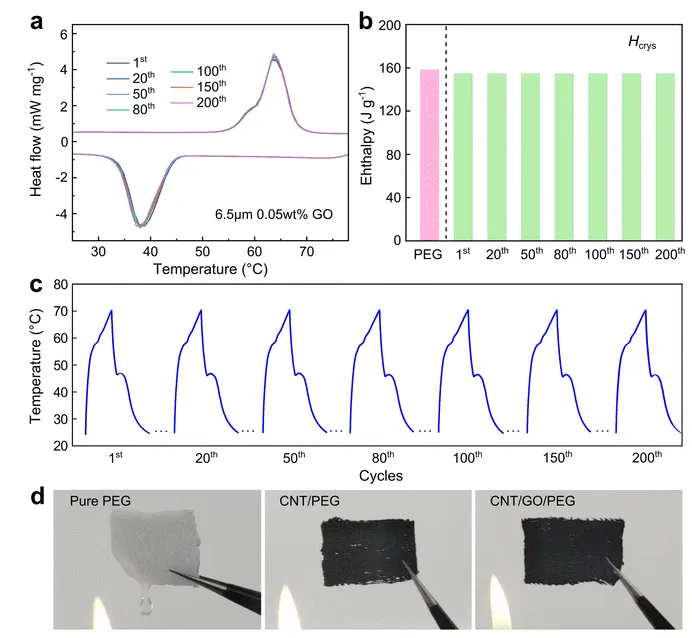

- Stable Phase Change and Leakage Resistance

- The network structure offers strong confinement, preventing polymer leakage and enhancing thermal stability across multiple cycles.

Figures (From Original Study)

- Figure 1: Preparation process of CNT/GO/PEG fibers using the expansion-impregnation method.

- Figure 2: The effect of GO content on PEG loading.

- Figure 3: Thermal conductivity of the composite fibers.

- Figure 4: Phase-change behavior of CNT/GO/PEG fibers.

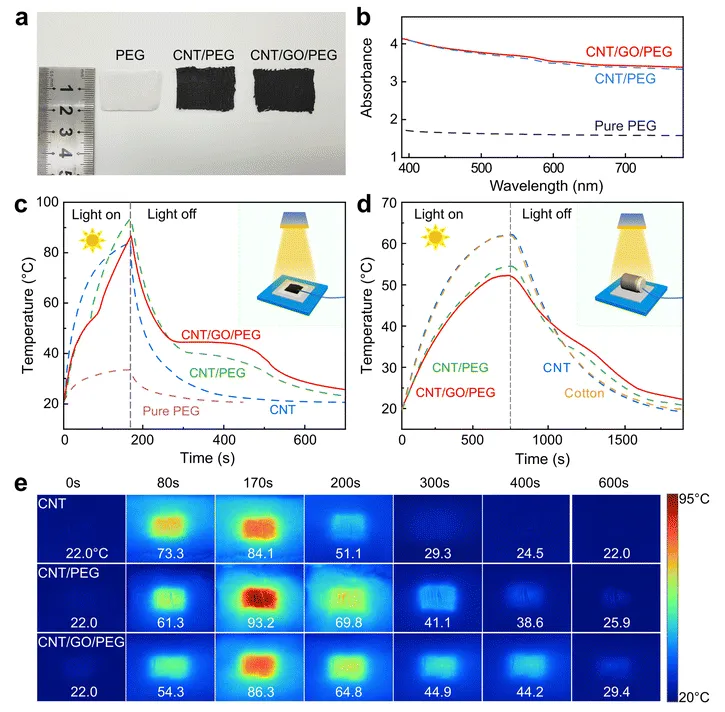

- Figure 5: Photothermal properties of various fabrics.

- Figure 6: Performance stability after multiple cycles of testing.

Conclusion and Applications

The in-situ impregnation strategy used to incorporate GO and PEG into CNT networks offers high polymer-loading capacity, stable thermal behavior, and improved insulation. This research highlights the potential of CNT/GO/PEG fibers for thermal management in wearable textiles and other energy-saving applications. With their low thermal conductivity, high phase-change enthalpy, and excellent thermal stability, these fibers pave the way for future innovations in smart textiles and energy storage systems.