Safety and Potential Risks of Carbon Nanotubes: Health and Environmental Impacts During Production

Introduction Carbon nanotubes (CNTs) are widely recognized for their exceptional mechanical, thermal, and electrical properties. Their applications span across various sectors such as electronics, energy storage, aerospace, automotive, and biomedical fields. However, the increasing use of CNTs has raised concerns about their safety, particularly with respect to human health and environmental impact during the production and handling processes. This article explores the potential risks associated with CNTs, the mechanisms through which these risks manifest, and strategies for mitigating negative impacts.

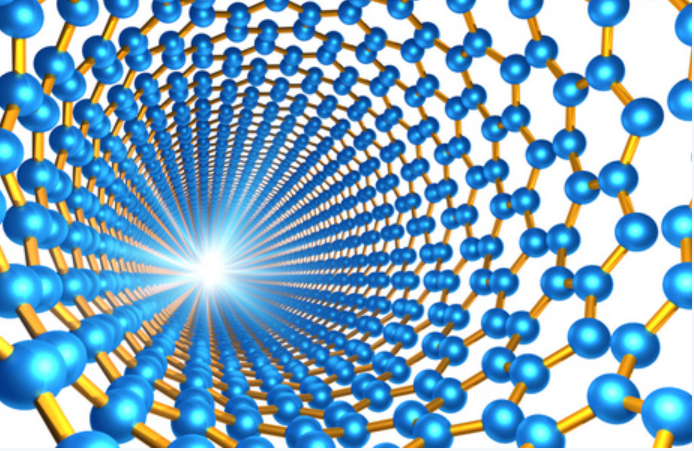

1. Overview of Carbon Nanotubes and Their Production Carbon nanotubes are cylindrical molecules made up of rolled graphene sheets. They are typically produced using methods such as chemical vapor deposition (CVD), arc discharge, and laser ablation. While these methods are effective for scalable production, they can generate byproducts and airborne nanoparticles that pose health and environmental challenges.

2. Health Risks Associated with CNT Exposure

2.1 Inhalation and Respiratory Effects One of the most concerning routes of CNT exposure is inhalation. Due to their nanoscale size and high aspect ratio, CNTs can penetrate deep into the lungs. Studies have shown that certain types of CNTs, especially long and rigid multi-walled carbon nanotubes (MWCNTs), can cause lung inflammation, fibrosis, and even carcinogenic effects similar to those of asbestos.

2.2 Skin and Eye Contact While less severe than inhalation, direct contact with CNTs may cause skin irritation and eye inflammation. The risk is particularly high in occupational settings where CNTs are handled in bulk or powder form.

2.3 Ingestion and Systemic Toxicity Accidental ingestion of CNTs through contaminated surfaces or materials may lead to gastrointestinal distress or systemic toxicity. Some in vivo studies suggest that CNTs may accumulate in organs such as the liver, kidneys, and spleen, potentially causing long-term health effects.

3. Environmental Risks of CNT Manufacturing

3.1 Airborne Nanoparticles CNT manufacturing processes can release nanoparticles into the air, contributing to atmospheric pollution. These particles can travel long distances and potentially impact both human populations and wildlife.

3.2 Water and Soil Contamination Wastewater from CNT production facilities may contain dispersed nanotubes or chemical byproducts that can infiltrate natural water bodies or soil, disrupting ecosystems and posing toxicity risks to aquatic life.

3.3 Waste Management Challenges Due to their unique properties and persistence, CNTs are not easily degraded in the environment. This raises challenges for disposal and recycling, as traditional waste treatment methods may not be effective.

4. Regulatory Landscape and Safety Guidelines

4.1 International Standards and Risk Assessments Regulatory bodies such as the European Chemicals Agency (ECHA), the U.S. Environmental Protection Agency (EPA), and the National Institute for Occupational Safety and Health (NIOSH) have begun evaluating the risks associated with CNTs. Exposure limits, classification guidelines, and labeling requirements are being developed to enhance worker safety.

4.2 Workplace Safety Measures Employers are encouraged to implement safety protocols such as:

- Using enclosed systems and local exhaust ventilation

- Providing personal protective equipment (PPE)

- Conducting regular health monitoring and training

- Ensuring proper storage and handling procedures

5. Sustainable Manufacturing and Safer Alternatives

5.1 Green Synthesis Approaches Innovations in green chemistry are enabling the synthesis of CNTs using bio-based precursors or low-temperature processes that reduce environmental impact.

5.2 Surface Functionalization for Safer Use Functionalization of CNT surfaces can improve biocompatibility and reduce toxicity. Coating CNTs with polymers or organic molecules can prevent unwanted interactions with biological tissues.

5.3 Lifecycle Analysis and Risk Management Conducting lifecycle assessments (LCA) helps quantify the environmental footprint of CNTs from cradle to grave. This data is vital for developing safer products and minimizing risks.

Conclusion As the commercial use of carbon nanotubes continues to expand, it is critical to address their potential risks to human health and the environment. With a proactive approach that includes risk assessments, regulatory compliance, and innovations in safe production methods, the industry can fully harness the benefits of CNTs while minimizing adverse impacts. Responsible development and transparent communication will be key to sustainable advancement in this field.