Corrosion and Scratch Resistance of Carbon Nanotube-Enhanced Automotive Coatings

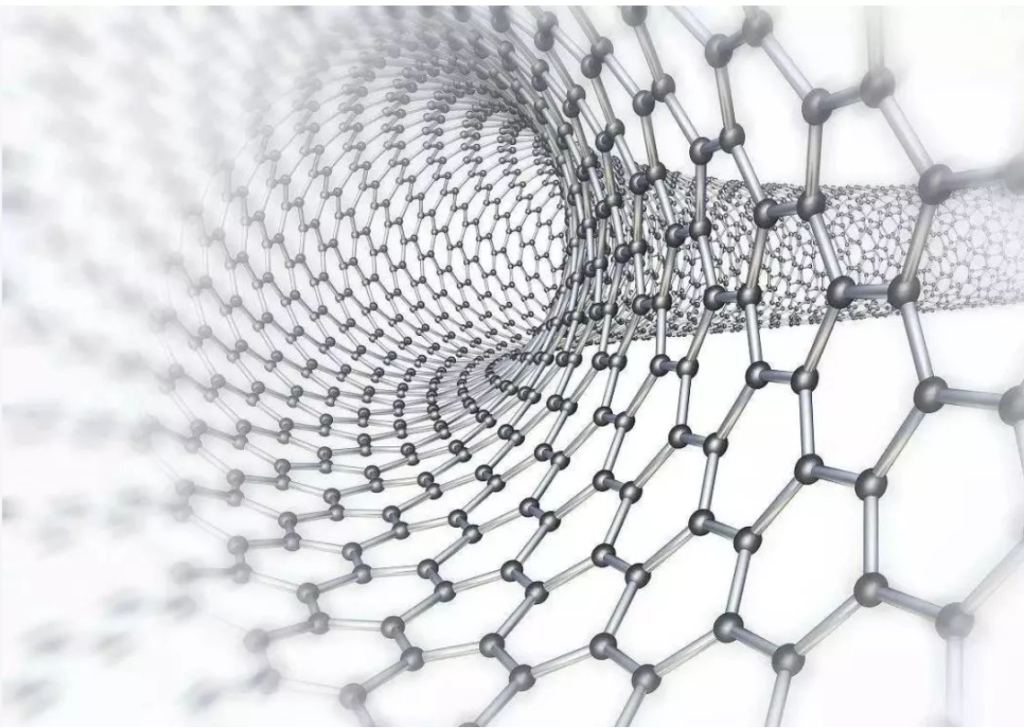

As automotive design pushes for longer durability, sleek aesthetics, and environmental resilience, advanced coatings are critical. Carbon nanotubes (CNTs), when incorporated into paint or clearcoat systems, significantly improve both corrosion resistance and scratch resistance, providing a competitive edge in modern automotive surfaces.

1. Key Challenges in Automotive Coatings

| Problem | Description | Consequences |

|---|---|---|

| Corrosion | Moisture, salt, and pollutants penetrate microcracks or defects | Rust, structural degradation |

| Scratching | Physical abrasion from debris, car washes, or keys | Loss of gloss, cosmetic damage |

| UV degradation | Sunlight weakens traditional polymers over time | Yellowing, peeling, cracking |

2. Why Use Carbon Nanotubes in Automotive Coatings?

CNTs bring multi-functional advantages when dispersed into coating matrices (e.g., polyurethane, epoxy, or acrylic systems):

| Property | Contribution to Coating |

|---|---|

| High aspect ratio | Bridges microcracks and enhances barrier function |

| Electrical conductivity | Enables electrostatic dissipation, reducing localized corrosion |

| Mechanical strength | Reinforces matrix to resist abrasion and deformation |

| Chemical stability | Maintains integrity under UV, salt, and solvent exposure |

3. Enhanced Corrosion Resistance Mechanism

✅ Barrier Effect: CNTs create a tortuous path for water, oxygen, and ions, reducing their diffusion through the coating.

✅ Cathodic Protection Support: In conductive coatings, CNTs distribute electrochemical current, slowing down localized corrosion.

✅ Microcrack Healing: Due to their high mechanical strength and flexibility, CNTs can bridge coating flaws, preventing early corrosion initiation.

Result:

CNT-enhanced coatings can improve corrosion resistance by up to 3–5× compared to standard coatings in salt spray or immersion tests.

4. Scratch Resistance Improvement

CNTs contribute to anti-scratch performance through:

-

Reinforcing the matrix: Increasing modulus and hardness without sacrificing flexibility.

-

Energy dissipation: Their nanoscale entanglement helps absorb and redistribute applied forces.

-

Self-lubricating effects: CNTs can reduce surface friction, minimizing wear from contact.

Test results:

Coatings with ~0.5–1 wt% CNTs can achieve up to 30–50% improvement in scratch resistance under ASTM D7027 or nanoindentation standards.

5. Application Strategies

🔧 Integration Methods:

-

Waterborne or solvent-based systems: CNTs can be functionalized for good dispersion.

-

Topcoat or mid-layer: For both cosmetic and functional roles.

-

Clearcoats: CNTs can maintain transparency at low concentrations.

🎨 Compatible with automotive coating technologies:

-

Electrodeposition (e-coat)

-

Spray application

-

Powder coatings

6. Real-World Benefits for Automakers

| Feature | Benefit |

|---|---|

| Enhanced surface durability | Fewer repairs and longer showroom finish |

| Extended corrosion protection | Reduced warranty claims and longer part life |

| Lightweight alternative to thicker coatings | Weight and cost savings |

| Smart coatings (conductive/anti-static) | For EVs and connected systems |

7. Conclusion: A Nano-Edge in Surface Protection

Carbon nanotubes are transforming traditional automotive coatings into multi-functional protection systems, offering not only visual brilliance but also enhanced resilience to environmental and mechanical damage.

CNTs enable coatings that are not only tougher—but smarter and longer-lasting. 🛡️🚗✨