Graphene-Based Thermal Interface Materials (TIMs): Redefining Heat Management

🔥 Introduction: Why Thermal Interface Materials Matter

As electronic devices become more compact and powerful, thermal management has emerged as a critical design challenge. Efficient heat dissipation ensures:

-

Device longevity

-

Stable performance

-

Prevention of thermal failure

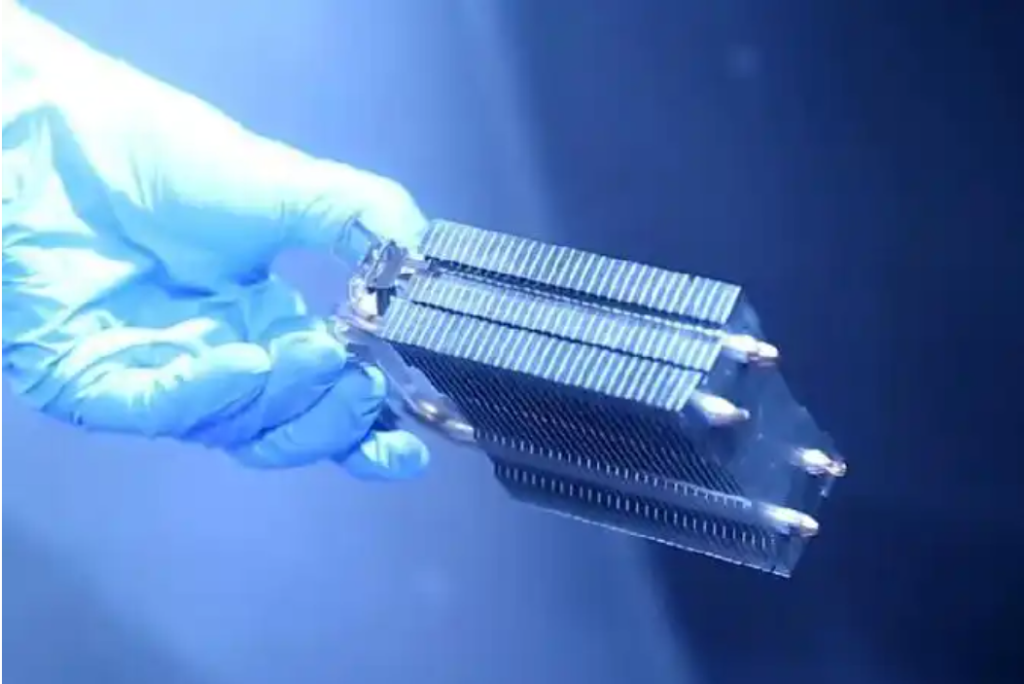

A major thermal bottleneck lies in the interface between heat-generating chips (e.g., CPUs, power transistors, LEDs) and heat sinks. Here, Thermal Interface Materials (TIMs) play a vital role by filling microscopic air gaps and improving thermal contact.

Conventional TIMs—such as silicone-based greases, phase-change materials, and polymer composites—often exhibit low thermal conductivity (<5 W/m·K) and poor mechanical durability under high temperature cycles.

This is where graphene emerges as a transformative filler.

🧬 Section 1: What Makes Graphene an Ideal Thermal Conductor?

Graphene exhibits one of the highest intrinsic thermal conductivities of any material—over 3000 W/m·K for monolayer pristine graphene. Even when used as a composite filler, graphene offers:

| Property | Benefit for TIMs |

|---|---|

| High aspect ratio | Forms continuous thermal pathways |

| Large surface area | Increases interface contact with matrix |

| 2D structure | Enhances in-plane heat spreading |

| Flexibility | Adapts to surface topology |

| Compatibility | Dispersible in polymers, silicones, epoxies |

Even 5–10 wt% loading of graphene or rGO can improve the thermal conductivity of a base matrix by 5–10×, while retaining workability.

🧪 Section 2: Types of Graphene-Based TIMs

Graphene materials can be incorporated into TIMs in various architectures:

-

Graphene Paste / Grease

-

Silicone or hydrocarbon base

-

Loaded with few-layer graphene or graphene nanoplatelets

-

Soft, reworkable, conformal

-

-

rGO-Filled Epoxy TIM

-

Rigid or semi-rigid composite

-

Good for vertical bonding in PCBs

-

Electrically insulating variants possible

-

-

Graphene Phase-Change TIMs (PCM)

-

Solid at room temp, melts at 40–70°C

-

Improved contact without pump-out issues

-

-

Graphene Film or Sheet TIMs

-

Aligned layers for ultra-high in-plane conductivity

-

Used in stacked chip packaging or high-power laser modules

-

⚙️ Section 3: Key Performance Parameters of Graphene TIMs

| Parameter | Importance | Typical Graphene TIM Values |

|---|---|---|

| Thermal conductivity | Core metric (W/m·K) | 5–15 W/m·K with 10 wt% graphene |

| Thermal resistance (R<sub>th</sub>) | Contact resistance (K·cm²/W) | <0.1 for soft pastes |

| Electrical insulation | Needed in many electronics | Can be tuned via rGO/GO type |

| Viscosity / flow | Dispensing behavior | Adjustable via matrix and graphene type |

| Pump-out stability | Long-term reliability | Graphene enhances viscosity retention |

In GrapheneRich NanoTech formulations, thermal conductivity can reach 10–12 W/m·K, depending on matrix selection and dispersion control.

🔋 Section 4: Application Areas

Graphene-based TIMs are revolutionizing thermal management across:

| Application | Heat Source | TIM Role |

|---|---|---|

| CPUs, GPUs | High-power chips | Paste/grease TIMs with graphene |

| Power modules | IGBTs, MOSFETs | rGO-epoxy composites |

| Automotive | EV batteries, inverters | Thermally conductive gap fillers |

| LED modules | High-lumen LED chips | Graphene-silicone PCMs |

| Telecom | 5G RF units | Thin graphene films for rapid heat spread |

| Aerospace | Avionics & radar | Lightweight, high-reliability composites |

Graphene’s light weight and high stability also make it ideal for space applications.

🧪 Section 5: Graphene TIM Formulation Considerations

Key factors in graphene TIM formulation:

-

Graphene Type: rGO, FLG, or hybrid structures

-

Matrix Selection: Silicone (soft), epoxy (rigid), PCM (smart)

-

Dispersion Stability: Agglomeration can reduce thermal transfer

-

Interface Compatibility: Must adhere to copper, aluminum, ceramics

-

Filler Orientation: Aligned graphene can further boost thermal paths

🔧 Our XFZ-TIM line includes:

-

High-purity rGO flakes (5–10 µm lateral)

-

Surface-treated for hydrophobic or polar matrices

-

Viscosity tuned from 10,000 to 100,000 cP

-

Electrical resistivity >10⁹ Ω·cm for safe electronics use

📊 Section 6: Lab Results & Benchmarking

Sample lab test of XFZ-TIM G-Paste (10 wt% graphene, silicone-based):

| Test | Value | Standard |

|---|---|---|

| Thermal conductivity | 11.5 W/m·K | ASTM D5470 |

| Volume resistivity | 1.2 × 10⁹ Ω·cm | ASTM D257 |

| Pump-out stability | >95% after 500 h @ 85°C | Internal |

| Bond line thickness | ~50 µm | Customized |

| Thermal impedance | 0.05 K·cm²/W | Excellent for CPUs |

Comparative tests showed 2–3× better heat dissipation over standard commercial greases under same power load.

🏭 Section 7: Why Choose GrapheneRich TIM Solutions

✅ Proprietary rGO and FLG production

✅ Custom formulation for your device needs

✅ Solvent-based and solvent-free options

✅ Lab to mass-production scale

✅ Global delivery and technical support

Our team works directly with:

-

Heat sink manufacturers

-

Thermal engineers in electronics

-

LED/EV system designers

-

Semiconductor packaging teams

🔮 Future Directions

Graphene-based TIMs are evolving toward:

-

Self-healing and phase-tunable TIMs

-

2D-graphene hybrid architectures (e.g., graphene-boron nitride)

-

Vertical graphene arrays for ultra-low thermal resistance

-

AI-designed graphene composites for optimized performance

As demand for compact, high-power devices grows, graphene TIMs will be essential for efficient, safe, and sustainable thermal engineering.

📞 Contact Us

Need custom graphene TIM solutions?

Reach out to us at graphenerich.com, or WhatsApp us at +86 136 1588 2924.

We offer free samples, formulation support, and OEM solutions worldwide.