Graphene for Thermal Management: Revolutionizing Heat Dissipation in Electronics and Batteries

Introduction

As electronic devices become more compact and powerful, efficient thermal management has become a critical challenge. Overheating shortens device lifespan, reduces performance, and raises safety concerns—especially in EV batteries, mobile phones, and 5G infrastructure.

Graphene, with its extraordinary thermal conductivity (up to 5300 W/m·K), offers a revolutionary solution. From thermal interface materials (TIMs) to battery heat spreaders, graphene enables faster, thinner, and more efficient heat dissipation than traditional materials like copper or aluminum.

1. Why Graphene Is an Ideal Thermal Material

Exceptional Properties:

-

Ultra-high thermal conductivity (10x that of copper)

-

Atomically thin & flexible

-

Chemically stable at high temperatures

-

Compatible with composites, polymers, and coatings

These traits allow graphene to be integrated into various thermal systems without adding bulk or weight.

2. Key Application Areas

a. Consumer Electronics

Graphene-based films are now used in:

-

Smartphones (e.g., Samsung Galaxy phones)

-

Tablets and laptops

-

Wearables and VR headsets

These films efficiently spread heat across the device surface, preventing hotspots and enabling higher performance chips without additional cooling fans.

b. Battery Thermal Management

In lithium-ion and solid-state batteries, uneven heat distribution can cause:

-

Capacity loss

-

Safety risks (thermal runaway)

-

Performance drops in cold/hot climates

Graphene-coated separators and graphene-enhanced heat spreaders:

-

Maintain thermal equilibrium between cells

-

Prevent hotspots during fast charging

-

Extend battery life cycles

c. 5G and Telecom Infrastructure

5G base stations and antennas generate intense localized heat.

Graphene composite pastes and foils:

-

Dissipate heat from power amplifiers and antennas

-

Improve long-term reliability in outdoor conditions

d. LED Lighting & Displays

Graphene-enhanced substrates help:

-

Prevent thermal degradation of LEDs

-

Allow thinner designs with higher light output

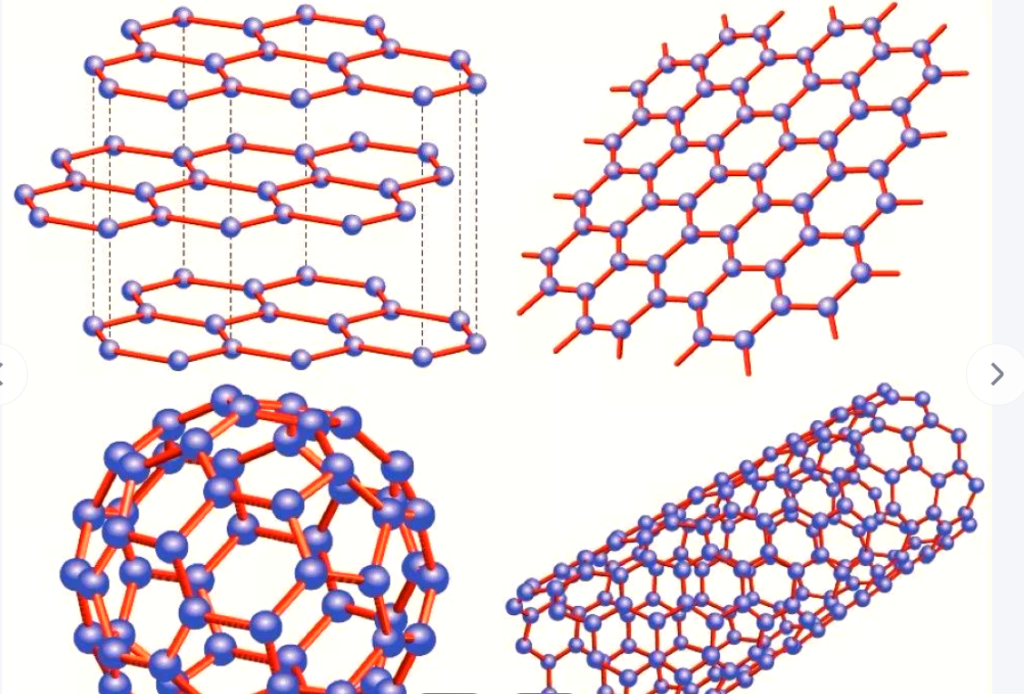

3. Forms of Graphene for Thermal Use

-

Graphene Films: For heat spreading on surfaces

-

Graphene Composites: Mixed into polymers or TIM pastes

-

Graphene-Coated Foils: Applied to battery packs or PCBs

-

Graphene Aerogels/Foams: Used in 3D structured heat sinks

Depending on the target application, manufacturers use graphene oxide (GO), reduced graphene oxide (rGO), or multi-layer graphene in custom formulations.

4. Case Studies and Commercial Adoption

-

Huawei: Uses graphene film cooling systems in its smartphones

-

Tesla & CATL: Experimenting with graphene-enhanced battery thermal regulation

-

IBM: Developed graphene TIMs for server CPUs, reducing junction temperature by up to 10°C

-

ZTE and Oppo: Adopt graphene cooling for 5G chipsets

5. Manufacturing Considerations

Challenges in mass production include:

-

Uniform dispersion in polymers or paste

-

Cost control for high-volume applications

-

Material stability under repeated thermal cycling

However, roll-to-roll CVD, inkjet printing, and spray coating techniques are making scalable production more viable each year.

Conclusion

Graphene’s entry into the thermal management domain marks a new frontier in electronics and energy storage. With its unmatched thermal conductivity and versatility, graphene is redefining how heat is handled in devices, paving the way for smaller, faster, and safer technologies.