Carbon Nanotubes in Cement and Concrete: Reinventing Construction Materials

The construction industry is under pressure to become more sustainable, durable, and efficient. Conventional cement and concrete, while inexpensive and widely used, suffer from issues like cracking, brittleness, and carbon emissions. Recent advancements in nanotechnology have introduced carbon nanotubes (CNTs) as high-performance additives that significantly improve the mechanical and functional properties of cement-based materials.

The Problem with Traditional Cement

Concrete is the most used material on Earth after water, but it has limitations:

-

Susceptible to cracking under stress or temperature cycles

-

Poor tensile strength and durability

-

Significant contributor to CO₂ emissions during cement production

The addition of nanomaterials like CNTs offers a path toward stronger, smarter, and greener concrete.

Why Use CNTs in Cement?

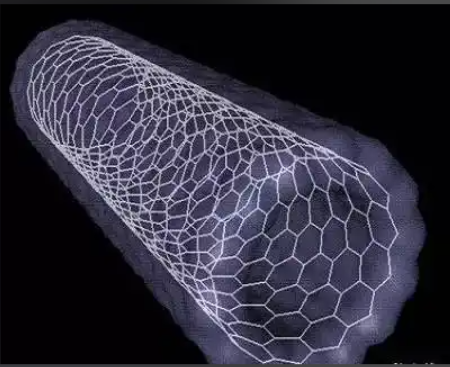

Exceptional Mechanical Properties

CNTs possess tensile strength 100x that of steel and are extremely lightweight, making them ideal for reinforcement at the nanoscale.

High Electrical Conductivity

This allows for the creation of self-sensing concrete, capable of monitoring its own structural health in real-time.

Crack Bridging and Porosity Reduction

CNTs fill microvoids in the cement matrix, reducing water penetration and crack propagation.

Applications in Smart and Sustainable Construction

1. Structural Reinforcement

CNT-enhanced cement exhibits up to 40% higher compressive strength and improved flexural performance—ideal for bridges, high-rises, and dams.

2. Self-Sensing Infrastructure

CNTs enable concrete to detect strain, cracks, and changes in pressure or humidity—reducing maintenance costs and enhancing safety.

3. Carbon Footprint Reduction

By allowing the use of less cement for the same performance, CNTs contribute to lowering CO₂ emissions during construction.

4. Thermal and Electrical Applications

CNT concrete can be used for heated pavements, anti-static flooring, and electromagnetic shielding in sensitive facilities.

Case Studies and Industry Adoption

-

University of Illinois: Developed CNT concrete sensors for detecting cracks in bridges

-

MIT and LafargeHolcim: Studied mechanical enhancements in CNT-blended cements

-

China Railway Construction Corp: Piloted CNT concrete for self-healing rail beds

Challenges in Deployment

-

Cost of CNTs, especially SWCNTs

-

Uniform dispersion in cement matrix remains a challenge

-

Regulatory frameworks for building materials still evolving

Solutions include the use of functionalized CNTs, ultrasonic mixing, and low-cost MWCNT production techniques.

Future Opportunities

-

Integration with AI-driven structural health monitoring

-

Use in 3D-printed concrete structures

-

Synergies with graphene and nano-silica for hybrid systems

Carbon nanotubes are redefining what’s possible in the world of cement and concrete. From smarter roads to longer-lasting buildings, CNT-enhanced construction materials are paving the way for a more resilient and intelligent infrastructure future.