How to Functionalize CNTs for Polymer Matrix Compatibility

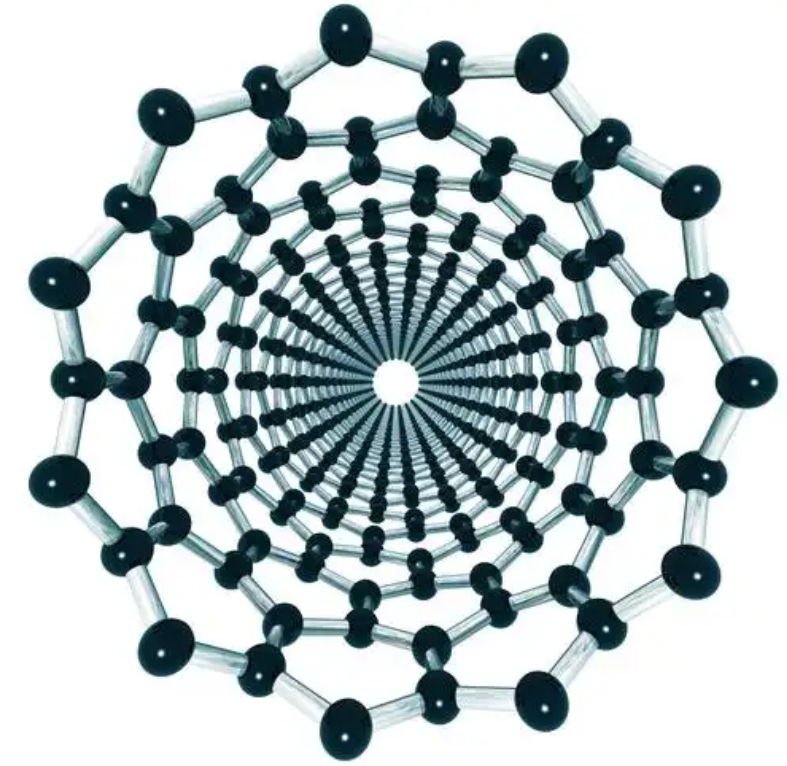

Carbon nanotubes (CNTs) have exceptional properties — high tensile strength, excellent electrical conductivity, and superior thermal performance. However, one critical issue has limited their industrial adoption in polymer composites: poor compatibility and dispersion within the polymer matrix.

Without proper surface treatment, CNTs tend to aggregate due to strong van der Waals forces, forming bundles that reduce their reinforcing efficiency and even weaken the composite. The solution lies in functionalization — modifying CNT surfaces chemically or physically to improve their interaction with the host polymer.

This article explains why functionalization is necessary, explores key techniques used in the field, and provides insights into industrial implementation for thermoplastics, thermosets, and elastomer-based composites.

1. Why CNT Functionalization Matters

1.1 The Dispersion Challenge

Pristine CNTs are inherently hydrophobic and have smooth, graphitic surfaces.

When mixed with polymers or solvents, they tend to cluster together, creating micron-sized bundles rather than forming a well-dispersed nanoscale network.

This aggregation leads to:

-

Non-uniform stress transfer,

-

Poor mechanical reinforcement,

-

Reduced electrical/thermal pathways, and

-

Processing difficulties (especially in extrusion or resin systems).

1.2 The Role of Functionalization

Functionalization introduces chemical groups or physical coatings on CNT surfaces to:

-

Improve interfacial bonding with the polymer matrix,

-

Enhance dispersibility in solvents or resins,

-

Enable custom performance tuning (conductive vs. structural), and

-

Facilitate hybrid material integration (e.g., CNT + graphene systems).

A small amount of functionalization can drastically change how CNTs interact with polymers, turning a clustered filler into a reinforcing, conductive network.

2. Types of CNT Functionalization

CNT functionalization can be broadly categorized into two approaches:

(1) Covalent functionalization and (2) Non-covalent functionalization.

Each has distinct advantages depending on the final application.

2.1 Covalent Functionalization

This method involves creating chemical bonds between functional groups and the CNT carbon lattice.

Common techniques include acid oxidation, amination, and grafting reactions.

(a) Oxidation / Carboxylation (–COOH, –OH)

CNTs are treated with mixed acids (e.g., HNO₃/H₂SO₄) to introduce carboxyl and hydroxyl groups.

-

Improves solubility in polar solvents and resins.

-

Enables further reactions (e.g., with epoxy, amine, or silane groups).

-

Typical loading: 0.1–1 wt% in polymer systems.

Example: Carboxylated CNTs form strong covalent bonds with epoxy or polyurethane matrices, enhancing tensile strength and impact resistance.

(b) Amine Functionalization (–NH₂)

After oxidation, CNT–COOH groups can react with ethylenediamine or other amines.

-

Improves interaction with thermoset resins (epoxy, phenolic).

-

Provides sites for further crosslinking or grafting.

-

Useful in adhesive and aerospace-grade composites.

(c) Silane Coupling

Silane agents (e.g., APTES, GPTMS) create a bridge between CNTs and polymer matrices.

-

Common in thermoplastics (PP, PA, PET) and rubbers.

-

Enhances compatibility without severe damage to CNT structure.

-

Good balance between processability and conductivity.

(d) Polymer Grafting

In this technique, polymer chains are grafted directly onto CNT surfaces by in-situ polymerization.

-

Ensures strong chemical anchoring and homogeneous dispersion.

-

Example: CNT-g-PMMA or CNT-g-PEEK composites.

-

Provides excellent mechanical reinforcement and dimensional stability.

Advantages:

-

Permanent bonding and high interfacial strength.

-

Tunable chemistry for specific polymer systems.

Drawbacks:

-

Potential damage to CNT structure (loss of conductivity).

-

More complex, costly processing.

2.2 Non-Covalent Functionalization

This method preserves CNT’s intrinsic electrical and mechanical properties by avoiding chemical bond formation. Instead, surfactants, polymers, or biomolecules wrap or adsorb onto CNT surfaces through π–π or van der Waals interactions.

(a) Surfactant-Assisted Dispersion

Common surfactants include SDS (sodium dodecyl sulfate), CTAB, and Triton X-100.

-

Reduces surface tension and prevents aggregation in solvents.

-

Ideal for aqueous dispersions or ink formulations.

-

Often used in conductive coatings and flexible electronics.

(b) Polymer Wrapping

Certain polymers (e.g., PVP, PEG, or PVDF) can wrap around CNTs physically.

-

Enhances compatibility with corresponding polymer matrices.

-

Retains CNT conductivity and flexibility.

-

Example: CNT/PVDF composites used for piezoelectric sensors.

(c) π–π Interaction with Aromatic Polymers

Polymers containing aromatic rings (e.g., polystyrene, polyimide) can interact directly with CNT surfaces.

This improves bonding without chemical modification.

Advantages:

-

Preserves CNT’s electrical and mechanical properties.

-

Simpler and safer than acid oxidation.

-

Scalable for mass production.

Drawbacks:

-

Weaker interfacial strength than covalent bonding.

-

Long-term stability may depend on processing conditions.

3. Matching CNT Functionalization to Polymer Types

Different polymers require different surface chemistry for optimal compatibility.

Below is a simplified compatibility guideline:

| Polymer Type | Recommended CNT Functionalization | Effect / Application |

|---|---|---|

| Epoxy, PU, Phenolic | Carboxyl (–COOH), Amine (–NH₂) | Improved bonding & curing reactivity |

| PE, PP (non-polar) | Silane, Alkyl, or Polymer grafting | Better dispersion & load transfer |

| PA, PET, PBT (polar thermoplastics) | Amine or Hydroxyl | Enhanced interfacial adhesion |

| Elastomers (NR, SBR, Silicone) | Silane or surfactant treatment | Flexibility and conductivity balance |

| PVDF, PVP, PEO | Non-covalent wrapping | Retains conductivity & flexibility |

4. Industrial Processing Considerations

4.1 Dispersion Methods

After functionalization, CNTs can be incorporated using:

-

Solution mixing (for coatings or films),

-

Melt compounding (for thermoplastics),

-

In-situ polymerization (for high-performance composites).

The choice depends on viscosity, CNT type, and desired property enhancement.

4.2 CNT Loading and Network Formation

Typically, 0.1–2 wt% CNTs are sufficient for mechanical reinforcement or conductivity.

Higher loadings may improve performance but complicate processing.

Uniform dispersion and percolation network formation are critical for achieving consistent properties across batches.

4.3 Hybrid Systems

Combining CNTs with graphene nanoplatelets (GNPs) or carbon black can optimize cost and performance balance — leveraging CNT’s 1D network and graphene’s 2D conductivity.

5. Applications Enabled by Functionalized CNTs

Functionalized CNTs have enabled a wide range of polymer-based technologies:

-

High-strength structural composites: Aerospace, automotive, and sports goods.

-

Conductive polymers: EMI shielding, ESD protection, antistatic coatings.

-

Flexible and printed electronics: CNT inks for touch sensors and films.

-

Thermal interface materials: Enhanced heat dissipation and stability.

-

Elastomeric sensors: Stretchable conductive networks for wearable devices.

The ability to tailor CNT surface chemistry gives manufacturers the flexibility to target both performance and processing efficiency.

6. Challenges and Future Directions

Despite progress, large-scale functionalization faces challenges:

-

Maintaining CNT structural integrity during acid or grafting treatments.

-

Achieving reproducible dispersion at industrial scale.

-

Managing environmental and safety aspects of chemical processing.

Ongoing research focuses on green functionalization methods — such as plasma treatment, supercritical CO₂ modification, or bio-based dispersants — offering sustainable routes for CNT-polymer integration.

Functionalization is the key to unlocking the full potential of carbon nanotubes in polymer composites.

By tailoring CNT surfaces through covalent or non-covalent modification, manufacturers can achieve:

-

Excellent compatibility and dispersion,

-

Strong interfacial bonding,

-

Tunable mechanical, electrical, and thermal performance.

Whether used in structural materials, flexible electronics, or smart sensors, functionalized CNTs bridge the gap between nanotechnology and real-world polymer engineering — enabling lighter, stronger, and more efficient materials for the next generation of applications.