CNT Growth by CVD – Equipment, Catalysts, and Process Control

How Chemical Vapor Deposition Enables High-Purity, Controllable Carbon Nanotube Production

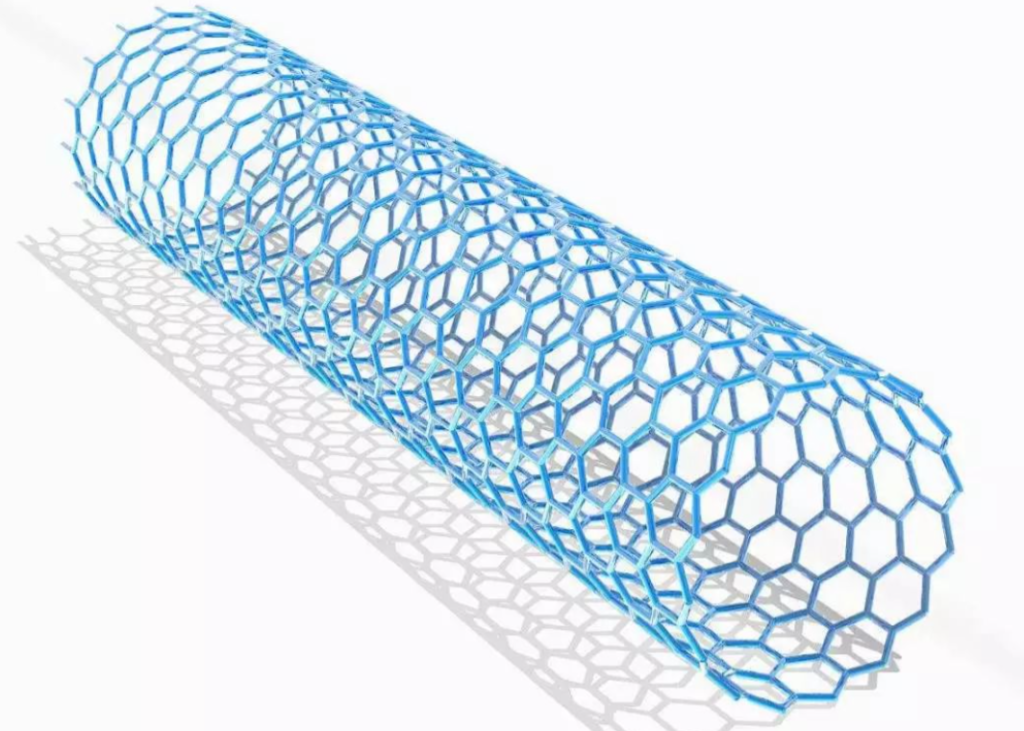

Chemical Vapor Deposition (CVD) remains the most widely adopted and industrially scalable method for producing carbon nanotubes (CNTs), including both single-walled (SWCNTs) and multi-walled (MWCNTs). Compared with arc discharge or laser ablation, CVD offers unmatched control over tube diameter, length, alignment, purity, and yield—critical parameters for electronics, composites, thermal interfaces, energy storage, and biomedical applications.

This article breaks down how CNT CVD works from an engineering perspective, covering reaction chambers, gas delivery, catalysts, substrates, temperature control, and how each parameter influences CNT morphology.

1. Why CVD for CNT Production?

Key Advantages

-

Scalable from lab to mass production (grams → kilograms/day).

-

Lower temperature than arc/laser (typically 600–900°C).

-

High purity, especially for vertically aligned CNT (VACNT).

-

Control of diameter through catalyst nanoparticle size.

-

Compatible with roll-to-roll manufacturing.

-

Works with many carbon sources (CH₄, C₂H₄, CO, acetylene).

Industrial Applications

-

CNT conductive additives (battery cathodes/anodes).

-

Electrically conductive plastics.

-

EMI shielding and RF absorption.

-

Vertically aligned CNT heat spreaders & TIMs.

-

CNT membranes and filters.

-

CNT sensors and biomedical carriers.

2. CVD System Overview – The Equipment

CVD reactors can be batch-type tube furnaces or continuous systems depending on production requirements.

2.1 Tube Furnace CVD (Lab or Pilot Scale)

Typical setup:

-

Quartz or alumina tube (50–200 mm diameter).

-

Heating zones (1–3 zones) with precise temperature control.

-

Gas inlet manifold for carbon precursor, hydrogen, argon/nitrogen.

-

Mass flow controllers (MFCs).

-

Exhaust system with hydrocarbon cracking protection.

-

Boat or substrate holder for catalysts.

Useful for:

-

R&D.

-

Catalyst optimization.

-

Small batch CNT synthesis.

2.2 Floating Catalyst CVD (FC-CVD, “Aerosol CVD”)

Used for large-scale MWCNT and CNT fiber/yarn production.

Equipment includes:

-

Atomizer or ultrasonic nebulizer for catalyst precursor (ferrocene, nickelocene).

-

High-temperature furnace (1000–1300°C).

-

Long vertical reactor (2–6 meters).

-

Gas-flow-driven CNT aerogel formation zone.

-

Collector chamber for direct fiber drawing or aerogel condensation.

Advantages:

-

Continuous production.

-

High throughput.

-

Produces spinnable CNT aerogels → CNT yarn and CNT sheets.

2.3 Plasma-Enhanced CVD (PECVD)

PECVD uses plasma (RF or microwave) to enable lower-temperature CNT growth (300–600°C).

Applications:

-

CMOS-compatible SWCNT synthesis.

-

Vertically aligned CNT arrays for electronics.

-

Field emission devices.

3. Catalyst Materials – The Heart of CNT Growth

CNT growth requires transition metal nanoparticles that catalyze hydrocarbon decomposition.

3.1 Catalyst Elements

Common metals:

-

Fe

-

Co

-

Ni

All three can produce SWCNTs and MWCNTs, but Fe is most frequently used due to:

-

Higher carbon solubility.

-

Stable nanoparticle formation.

-

High activity in CH₄ and CO decomposition.

Other metals:

-

Mo, Cr, Pd, Pt used as promoters or diameter-control agents.

3.2 Catalyst Forms

(1) Thin-film catalysts (for aligned CNT)

-

Fe, Fe/Al₂O₃, Fe/Mo sputtered films (1–5 nm).

-

Thermal annealing causes the film to break into nanoparticles → controls CNT diameter.

(2) Supported catalysts (powder forms)

-

Fe/Al₂O₃

-

Fe/SiO₂

-

Fe/MgO

-

CoMo/MgO (HiPco-like systems using CO)

Used for high-yield CNT powders.

(3) Floating catalysts (dissolved metal precursors)

-

Ferrocene (Fe)

-

Nickelocene (Ni)

-

Cobaltocene (Co)

Used in aerosol CVD to generate CNT aerogels/fibers.

3.3 Catalyst Particle Size → CNT Diameter

CNT diameter (D) is typically proportional to nanoparticle diameter.

SWCNT:

-

0.8–3 nm → requires nanoparticles 0.5–2 nm.

MWCNT:

-

5–50+ nm → produced from larger nanoparticles or aggregated clusters.

Controlling nanoparticle size is one of the most important steps in CVD process optimization.

4. Carbon Sources – Choosing the Right Hydrocarbon

| Carbon Source | Temp (°C) | Notes |

|---|---|---|

| Methane (CH₄) | 800–1000 | Cleanest carbon, low amorphous carbon. |

| Ethylene (C₂H₄) | 650–800 | High yield, faster growth rate. |

| Acetylene (C₂H₂) | 550–750 | Very reactive, but prone to soot. |

| Carbon Monoxide (CO) | 800–1200 | Used in HiPco for SWCNT. |

| Ethanol | 700–900 | Eco-friendly, used in Japan for SWCNT. |

Methane is often preferred for high-purity CNTs with minimal defects.

5. Process Parameters – How to Control CNT Morphology

CNT growth is highly sensitive to temperature, gas ratios, catalyst activation, and growth time.

5.1 Temperature

Effects:

-

Low temp (<650°C): poorly graphitized CNTs, defects.

-

Optimal temp (700–900°C): high-quality graphitic CNT walls.

-

High temp (>1000°C): risk of catalyst sintering → larger tubes.

5.2 Gas Composition

Typical gases:

-

H₂: Prevents catalyst oxidation, adjusts carbon deposition rate.

-

Ar/N₂: Carrier gas for flow control.

-

Carbon precursor: hydrocarbon vapors.

H₂ concentration influences:

-

CNT wall thickness.

-

Purity (reduced amorphous carbon).

-

Catalyst lifetime.

5.3 Growth Time

Short duration (seconds–minutes):

-

Vertical aligned CNT (VA-CNT).

Long duration (minutes–hours):

-

CNT powder with long lengths (10–1000 μm).

-

CNT aerogels for fiber spinning.

Growth rate example:

-

Ethylene CVD: 20–100 μm/min growth rate for aligned CNT.

5.4 Pressure Control

Low-pressure CVD (LPCVD):

-

Produces cleaner SWCNT.

-

Minimizes amorphous carbon deposition.

Atmospheric CVD (APCVD):

-

Simpler equipment.

-

Higher yield, good for MWCNT.

5.5 Catalystpretreatment & Activation

Typical steps:

-

Heat catalyst in H₂ or Ar/H₂ mixture.

-

Nanoparticle formation through dewetting.

-

Introduce carbon precursor.

Proper activation is essential for consistent CNT diameter and purity.

6. Types of CNT Produced by CVD

1. Vertically Aligned CNT (VACNT)

-

Used in thermal interface materials (TIMs), heat spreaders, sensors.

-

Requires thin-film catalyst and controlled substrate chemistry.

2. CNT Powders (MWCNT & SWCNT)

-

Used in conductive additives, polymers, rubbers, concrete.

3. CNT Forest → CNT Sheets

-

Drawn directly from furnace output.

-

Used for EMI shielding, structural composites.

4. CNT Fibers / CNT Yarn

-

Produced by aerosol CVD with aerogel spinning.

-

Used in aerospace, wearables, and energy storage.

7. Quality Control & Characterization

To ensure consistent CNT quality, manufacturers typically measure:

Key Parameters

-

CNT diameter distribution (TEM).

-

Wall thickness / number of walls (TEM, Raman).

-

ID/IG ratio (Raman) → defect level.

-

Purity (% CNT vs. catalyst residue).

-

Aspect ratio (length/diameter).

-

Surface area (BET).

-

Electrical conductivity.

-

Bulk density (tap density for battery additives).

Typical High-Quality Values

-

ID/IG < 0.1 (highly graphitized).

-

Metal residue < 1–5%.

-

Surface area 150–400 m²/g (MWCNT).

-

Diameter 5–15 nm (common industrial spec).

8. Industrial Equipment & Scalability

Entry-Level R&D Systems

-

1–2 inch quartz tube.

-

Manual MFCs.

-

Electric furnace (3-zone).

Pilot-Line Systems

-

4–6 inch tube furnaces.

-

Automated gas flow & recipe control.

-

Larger catalyst boats / rotating reactors.

Industrial Production Lines

-

Floating catalyst CVD producing 30–300 kg/day.

-

Reactor length 4–6 meters.

-

Automated CNT aerogel collection systems.

-

Purification (acid washing, drying, milling).

-

Packaging under inert atmosphere.

Graphene Echo or similar suppliers can provide tailored CNT types depending on application.

9. Summary – What Determines CNT Quality in CVD?

The Four Critical Components

1. Catalyst

-

Type, composition, particle size

→ controls diameter & growth rate.

2. Temperature

-

700–900°C ideal for strong graphitic structure.

3. Gas Chemistry

-

Hydrocarbon type + H₂ ratio

→ influences purity & wall quality.

4. Process Stability

-

Flow control

-

Pressure control

-

Catalyst lifetime

→ ensures consistent batches.

CVD remains the backbone of commercial CNT manufacturing due to its scalability, controllability, and compatibility with various catalyst systems and carbon precursors. Whether producing high-purity SWCNT for electronics or cost-effective MWCNT for batteries and composites, optimizing equipment, catalyst design, and process control is essential.