CNTs as Catalyst Supports – For Fuel Cells and Hydrogen Reactions

Why Carbon Nanotubes Are Becoming the Next-Generation Catalyst Support

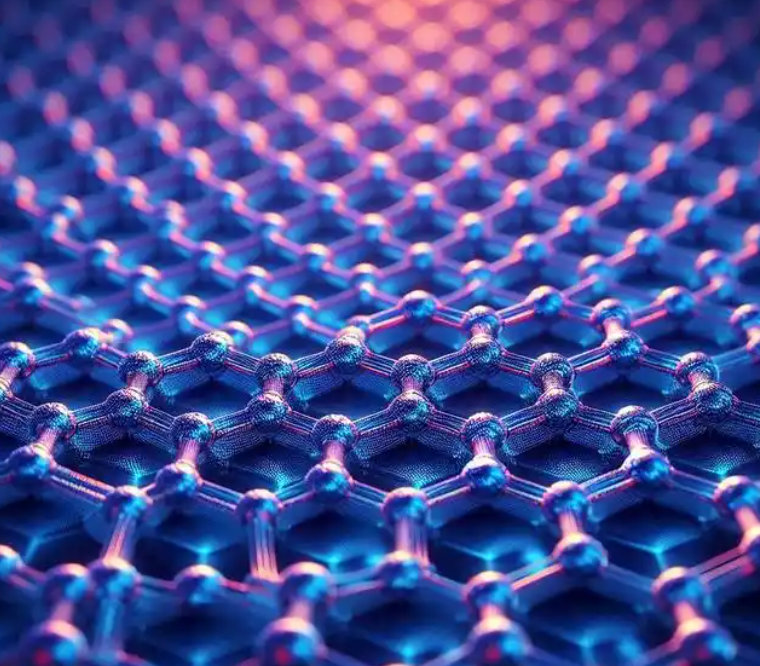

Carbon nanotubes (CNTs) are emerging as one of the most promising catalyst supports for fuel cells, hydrogen evolution reactions (HER), oxygen reduction reactions (ORR), and a broad range of electrochemical and thermochemical processes. Their unique 1D nanoscale geometry and intrinsic electrical, chemical, and thermal properties enable catalyst systems that perform better, last longer, and reduce reliance on expensive noble metals.

This article explains why CNTs are ideal catalyst supports, how they enhance hydrogen-related reactions, and what industries are currently deploying CNT-supported catalysts at scale.

1. Why CNTs Make Excellent Catalyst Supports

1.1 High Electrical Conductivity

CNTs provide a continuous network of conductive pathways, significantly reducing charge-transfer resistance in electrochemical systems such as:

-

Proton Exchange Membrane Fuel Cells (PEMFC)

-

Alkaline Fuel Cells (AFC)

-

Direct Methanol Fuel Cells (DMFC)

-

Electrolyzers for hydrogen production

Their conductivity (10³–10⁶ S/m depending on type) improves:

-

Electron mobility

-

Catalyst activation

-

Electrochemical response speed

Compared with conventional carbon black, CNT networks offer faster electron transport and higher utilization of active sites.

1.2 Large Surface Area for Catalyst Loading

CNTs exhibit surface areas of 200–800 m²/g, providing abundant anchoring points for:

-

Platinum (Pt) nanoparticles

-

Pt–Ru, Pt–Co, or Pt–Ni alloy catalysts

-

Non-noble metal catalysts (Fe–N–C, Co–N–C)

-

Metal oxides (MnO₂, RuO₂, TiO₂)

Their tubular morphology enables uniform catalyst dispersion, preventing agglomeration and ensuring longer catalyst lifetime.

1.3 Excellent Chemical and Thermal Stability

CNTs maintain structure and conductivity under harsh reaction conditions:

-

Strong acids and bases

-

High voltages

-

Elevated temperatures

-

Repeated redox cycling

This stability results in slower catalyst degradation and better long-term performance than carbon black or graphene oxide in many catalytic systems.

1.4 Tunable Surface Functionalization

CNTs can be modified through:

-

Acid oxidation (–COOH, –OH groups)

-

Plasma treatment

-

Nitrogen or sulfur doping

-

Polymer coating (PANI, PEDOT, Nafion)

These functional groups improve:

-

Catalyst anchoring

-

Hydrophilicity

-

Charge transfer

-

Reaction selectivity

Functionalized CNTs often show 2–10× higher catalytic activity compared to untreated CNT supports.

2. CNT-Supported Catalysts in Fuel Cells

2.1 Platinum (Pt) Catalysts on CNTs

CNT-supported Pt catalysts show:

-

Higher mass activity

-

Lower Pt loading requirements

-

Better durability against carbon corrosion

Typical performance gains:

-

30–50% higher electrochemical active surface area (ECSA)

-

20–40% increased ORR activity

-

2–5× longer catalyst life

This is especially valuable for PEM fuel cells used in:

-

Passenger EVs

-

Buses and heavy-duty vehicles

-

Stationary backup power

-

Aerospace and UAV fuel cell systems

2.2 CNTs for Non-Noble Metal Fuel Cell Catalysts

CNTs support high-performance catalysts such as:

-

Fe–N–C

-

Co–N–C

-

Mn–N–C

Advantages:

-

Low cost

-

High ORR activity

-

Improved tolerance to methanol crossover (DMFC)

Many research groups report non-noble CNT catalysts approaching Pt activity in alkaline fuel cells.

3. CNTs in Hydrogen Reaction Catalysis

CNTs play an increasingly important role in hydrogen-related reactions, including:

3.1 Hydrogen Evolution Reaction (HER)

CNTs support catalysts such as:

-

MoS₂

-

Ni₂P

-

CoP

-

FeS₂

-

Pt

CNTs improve:

-

Charge transfer

-

Reaction kinetics

-

Stability during cycling

In alkaline electrolyzers, CNT-supported HER catalysts achieve:

-

Low overpotentials (20–80 mV)

-

High current densities (>500 mA/cm²)

-

Long operation life

3.2 Oxygen Evolution Reaction (OER) and Overall Water Splitting

CNT networks enhance conductivity and robustness for catalysts such as:

-

NiFe LDH

-

Co₃O₄

-

IrO₂

-

RuO₂

This enables efficient dual HER/OER systems for:

-

PEM electrolyzers

-

Alkaline water electrolyzers

-

Solar-driven water splitting

3.3 Hydrogen Storage Reaction Catalysts

CNTs support metal hydrides or complex hydrides, improving:

-

Hydrogen absorption/desorption kinetics

-

Thermal management

-

Cyclability

Applications include:

-

Solid-state hydrogen storage tanks

-

On-board hydrogen systems

-

Portable hydrogen cartridges

4. Industrial Applications and Commercial Deployment

CNT-supported catalysts are entering full-scale deployment across multiple sectors.

4.1 Fuel Cell Vehicles (FCEVs)

Automotive OEMs and Tier-1 suppliers increasingly use CNT-supported catalysts to:

-

Reduce Pt loading

-

Increase catalyst lifespan

-

Improve performance at low humidity

This is especially relevant for high-mileage applications:

-

Buses

-

Trucks

-

Logistics vehicles

4.2 Industrial Electrolyzers for Green Hydrogen

CNT-supported electrodes are used in:

-

PEM electrolyzers

-

AEM electrolyzers

-

Industrial alkaline electrolyzers

Benefits include:

-

Lower energy consumption

-

Longer electrode durability

-

Lower noble-metal usage

4.3 Hydrogen Sensors

CNT-supported metal nanoparticles (Pd, Pt, Au) are used for ultra-sensitive hydrogen leak detection in:

-

Fueling stations

-

Hydrogen storage systems

-

Aerospace hydrogen infrastructure

CNT networks enable:

-

Rapid response times (<1 s)

-

Low detection limits (<10 ppm)

5. Challenges & Future Potential

Remaining Challenges

-

CNT purity and metal residue control

-

Consistency of catalyst anchoring sites

-

Scalable functionalization processes

-

Cost reduction for industrial catalysts

The combination of CNT catalyst supports + low Pt loading + advanced functionalization is pushing fuel cells and hydrogen technologies toward:

-

Higher efficiency

-

Lower cost

-

Longer lifetime

-

Mass commercial adoption

As hydrogen economies expand globally, CNT-supported catalysts will become a core enabling material across the entire hydrogen value chain—from production to storage to end-use power systems.