CNTs in Rubber Compounds – Reinforcement and Conductivity

How Carbon Nanotubes Upgrade Mechanical Strength, Durability, and Electrical Performance in Rubber Materials

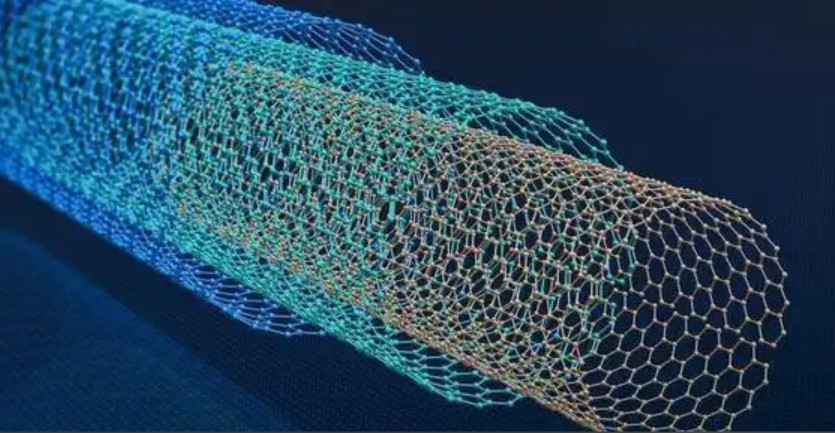

Carbon nanotubes (CNTs) are becoming one of the most advanced additives used in modern rubber formulations. Their high aspect ratio, 1D nanostructure, and intrinsic electrical/mechanical properties bring significant improvements in strength, conductivity, anti-static performance, and durability—far beyond what traditional fillers like carbon black or silica can offer at similar loading levels.

This article explains how CNTs reinforce rubber, why they provide strong conductivity, and how manufacturers can use CNTs in tires, seals, belts, hoses, and anti-static rubber products.

1. Why CNTs Are Effective in Rubber Compounding

Rubber formulators use CNTs because they provide multifunctional reinforcement:

-

Higher mechanical strength

-

Better tear and abrasion resistance

-

Permanent electrical/anti-static conductivity

-

Lower filler loading compared with carbon black

-

Enhanced thermal stability

These benefits mainly come from the unique nanostructure of CNTs.

1.1 High Aspect Ratio and Strong Interface Interaction

Typical CNTs have:

-

Length: 1–20 μm

-

Diameter: 10–20 nm

-

Aspect ratio: 100–1000+

This allows CNTs to:

-

Form strong percolating networks

-

Bond well with rubber chains

-

Improve mechanical load transfer

Even at low concentrations, CNTs dramatically reinforce rubber matrices.

1.2 Superior Electrical Conductivity

CNTs can create a conductive network inside the rubber at very low loading levels:

-

Percolation threshold: 0.1–1.0 wt%

-

Surface resistivity: 10⁶–10⁸ Ω/sq for anti-static compounds

-

Volume resistivity: 10¹–10³ Ω·cm depending on formulation

Compared with carbon black, CNTs:

-

Require much less loading

-

Provide more stable conductivity

-

Are less sensitive to humidity or aging

1.3 High Mechanical Strength

CNTs improve:

-

Tensile strength

-

Elongation at break

-

Tear resistance

-

Abrasion resistance

-

Fatigue resistance

This is due to strong interfacial bonding and efficient stress distribution.

1.4 Enhanced Thermal and UV Stability

CNT-reinforced rubber withstands:

-

Higher continuous temperatures

-

Thermal cycling

-

Oxidative degradation

-

UV exposure

This makes CNTs suitable for high-performance industrial and automotive rubber applications.

2. Mechanical Improvements from CNT-Reinforced Rubber

CNT addition generally results in:

✔ 10–40% higher tensile strength

✔ 20–50% higher modulus

✔ 15–35% increased tear resistance

✔ 30–60% improved abrasion resistance

Actual performance depends on:

-

CNT type (MWCNT, SWCNT, functionalized CNTs)

-

Rubber matrix (NR, SBR, EPDM, NBR, FKM, silicone etc.)

-

Dispersion quality

-

Processing method

Even low dosages (0.1–3 wt%) can yield strong mechanical enhancement.

3. Electrical Conductivity in Rubber Using CNTs

CNTs create long-range conductive pathways due to their 1D tubular geometry.

3.1 Percolation Threshold

CNTs have a much lower percolation threshold compared with carbon black:

-

CNTs: 0.1–1 wt%

-

Carbon black: 10–20 wt%

This means:

-

Less filler → better mechanical properties

-

Lower density → weight reduction

-

More stable electrical performance

3.2 Types of Conductive Rubber Applications

CNT-filled rubber is widely used in:

-

Anti-static footwear

-

Conductive conveyor belts

-

Fuel hoses and seals

-

Industrial rollers

-

Printer/copier rubber components

-

EV anti-static parts

-

High-temperature conductive rubber

CNTs maintain conductivity even under:

-

Stretching

-

Bending

-

Compression

-

Aging

4. How CNTs Improve Different Rubber Types

4.1 Natural Rubber (NR) and SBR

Benefits:

-

Better tensile strength

-

Higher tear resistance

-

Lower hysteresis

-

Strong anti-static performance

Applications:

-

Tires

-

Belts

-

Vibration-isolation parts

4.2 EPDM

Benefits:

-

Electrical conductivity for weather-resistant rubber

-

Improved thermal aging

-

Low percolation threshold

Applications:

-

Automotive rubber seals

-

Outdoor conductive rubber components

4.3 NBR and HNBR

Benefits:

-

Oil-resistant rubber with added conductivity

-

Better abrasion and fatigue resistance

Applications:

-

Fuel system seals

-

Conductive hoses

-

O-rings

4.4 Silicone Rubber (VMQ)

CNTs compensate silicone’s low conductivity and weak tear strength:

-

Higher tear resistance

-

Conductive and anti-static silicone elastomers

-

Stable at high temperatures (200–300°C)

Applications:

-

Electronics

-

Medical devices

-

Flexible sensors

5. Dispersion Considerations and Practical Guidelines

To maximize CNT performance, dispersion is the key.

5.1 Mixing Methods

Recommended:

-

Two-roll mill

-

Internal mixer (Banbury)

-

Latex mixing for NR

-

Masterbatch production

Masterbatch is often preferred for:

-

Consistent dispersion

-

Reduced dust

-

Easier processing

5.2 CNT Concentration Guidelines

Common loading levels:

-

0.5–3 wt% for mechanical reinforcement

-

0.1–1.0 wt% for conductivity

-

2–5 wt% for high-strength applications

Higher dosages may reduce elongation if dispersion is not optimized.

5.3 Functionalized CNTs

Carboxylated, hydroxylated, or amine-functionalized CNTs:

-

Improve compatibility with polar rubbers

-

Enhance mechanochemical bonding

-

Reduce agglomeration

-

Enable more uniform conductivity

Ideal for EPDM, NBR, and silicone systems.

6. Industrial and Commercial Applications

CNT-filled rubber is already used in:

6.1 Tires

-

Lower rolling resistance

-

Better wet grip

-

Higher tread life

-

Conductive pathways for EV tires

6.2 Anti-Static Rubber Components

-

Conveyor belts

-

Flooring materials

-

Fuel hoses

-

Printing rollers

-

ESD gaskets

CNTs provide stable ESD performance across temperature and humidity variations.

6.3 Automotive Rubber Parts

-

Engine mounts

-

Bushings

-

Weather seals

-

Turbo hoses

CNTs offer performance advantages vs. carbon black, especially for EV anti-static requirements.

6.4 High-Temperature Rubber Components

Silicone and fluororubber reinforced with CNTs are used in:

-

Aerospace

-

Industrial heating systems

-

Sensors

-

High-temperature seals

7. Market Outlook for CNT-Reinforced Rubber

The demand for CNT rubber additives is growing due to:

-

Electrification of vehicles

-

Stricter anti-static regulations

-

Lightweight and high-strength requirements

-

Growth of industrial automation

Analysts expect double-digit annual growth as CNT price and dispersion technologies continue to improve.

Carbon nanotubes offer a powerful multifunctional upgrade for rubber compounds, delivering:

-

Stronger mechanical properties

-

Permanent electrical conductivity

-

Better durability and aging resistance

-

Lower filler loading requirements

-

Improved performance for EV, industrial, and specialty rubber applications

For rubber manufacturers, CNTs are becoming a mainstream additive that delivers high-value performance with good compatibility across multiple rubber systems.