CNT Safety and Environmental Impacts – What Manufacturers and End Users Should Know

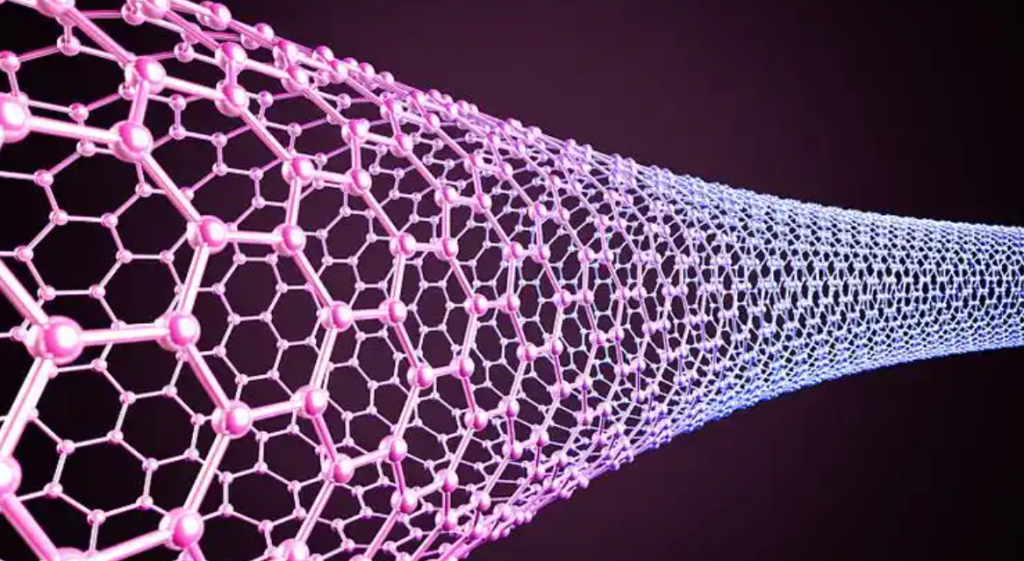

Carbon nanotubes (CNTs) are now widely used in electronics, composites, coatings, batteries, and emerging biomedical technologies. As production scales and applications expand, questions about safety, handling, and environmental impact are becoming increasingly important for manufacturers, customers, and regulatory bodies.

CNTs are not inherently unsafe—but like many advanced materials, they require proper understanding, responsible use, and compliance with global standards. This article provides a clear, industry-friendly overview of the safety profile of carbon nanotubes, how to handle them correctly, and what current scientific research says about environmental impact.

1. Why Safety Matters for CNT Materials

CNTs have unique nanoscale properties: high aspect ratio, high surface area, and strong interactions with biological and environmental systems. These characteristics give CNTs exceptional performance advantages—but also mean they must be handled like other engineered nanomaterials.

Key reasons for safety attention:

• Inhalation exposure must be controlled

Dry CNT powders can become airborne if not handled properly.

• Material forms behave differently

CNT powders, CNT dispersions, CNT composites, and CNT films have different risk levels.

• Global regulations are increasing

EU REACH, US NIOSH, ISO nanomaterial standards, and China’s new chemical regulations all require documentation and responsible practices.

• Customers expect safe, certified materials

Especially in electronics, battery manufacturing, construction, and healthcare.

2. Are CNTs Safe? What Current Research Shows

Safety depends heavily on CNT type, purity, and exposure route. Modern CNT products—especially purified, short-length, or functionalized CNTs—perform significantly better in toxicology studies than early-generation materials.

2.1 Inhalation Studies

Current scientific consensus shows:

✔ Short CNTs (<5 μm)

Lower risk, easier for the body to clear.

✔ Functionalized CNTs

Reduced inflammation and easier dispersion.

✔ CNTs embedded in composites or coatings

Extremely low risk—fibers are locked inside the matrix.

✔ Liquid dispersions

Minimal airborne exposure.

⚠ Dry, long, entangled CNT powders

Require proper protective equipment and ventilation.

NIOSH (USA) recommends an exposure limit: 1 µg/m³ (8-hour TWA) for CNTs.

This guideline is widely followed as a best-practice benchmark.

2.2 Skin Contact

CNTs do not penetrate intact skin.

Mild mechanical irritation may occur, similar to handling carbon black or fine powders.

Best practice: gloves + avoid rubbing.

2.3 Oral Exposure

CNTs are not absorbed efficiently through the digestive system.

Most studies show low toxicity when ingested.

2.4 Aquatic and Environmental Impact

Key findings:

-

CNTs tend to settle and bind to organic matter in water.

-

CNTs degrade slowly, but natural oxidation and microbial processes break them down over time.

-

Environmental impact depends on concentration and surface functionalization.

Environmental risk is considered manageable with proper waste handling.

3. Different CNT Forms = Different Safety Levels

Not all CNT products behave the same. Here is the industry-accepted hierarchy:

| CNT Form | Safety Level | Comment |

|---|---|---|

| CNT powder (dry) | Highest precaution | Can become airborne, needs strict controls |

| CNT masterbatch | Low concern | CNTs locked in polymer |

| CNT conductive paste/ink | Low concern | Liquid form, minimal inhalation risk |

| CNT films / yarns | Very low concern | Strong structural confinement |

| CNT-reinforced composites | Lowest concern | CNTs fixed permanently in matrix |

For most end applications (electronics, batteries, composites), CNTs are “locked in” and present minimal exposure.

4. Industrial Handling Guidelines

To safely manage CNT materials, follow these best practices widely adopted by global manufacturers:

4.1 Engineering Controls

-

Local exhaust ventilation (LEV)

-

HEPA filtration systems

-

Enclosed mixing or weighing stations

4.2 Personal Protective Equipment (PPE)

-

N95 / P100 respirators for powder handling

-

Nitrile gloves

-

Protective clothing

-

Safety goggles

4.3 Safe Work Practices

-

Avoid dry sweeping

-

Use wet cleaning or HEPA vacuum

-

Keep containers closed

-

Train operators on nanomaterial handling

5. Disposal and Environmental Management

CNTs should be treated like high-value industrial materials with controlled disposal.

✔ Solid Waste

-

Collect in sealed containers

-

Dispose according to local hazardous waste guidelines

✔ Liquid Waste (ink, dispersion)

-

Coagulate using polymer flocculants, then treat as solid waste

✔ CNT-Composite Waste

Considered low risk—handle like standard polymer waste unless contaminated with chemicals.

✔ Wastewater

CNTs settle easily; filtration + activated carbon improves removal.

6. Regulatory Landscape

CNTs are recognized under numerous regulatory systems:

• EU REACH

Registration required for CNTs sold in the EU.

Many CNTs are registered with tonnage bands and safety dossiers.

• NIOSH (USA)

Recommends occupational exposure limit of 1 µg/m³.

• ISO Standards

ISO/TS 12901-2: Guidelines for nanomaterial occupational safety.

ISO/TR 19716: CNT toxicology review.

• China

CNTs classified as new chemical substances; documentation and SDS required.

• Japan / Korea / Canada

Nanomaterial regulatory frameworks apply.

For exporting CNT-based products, an SDS aligned with GHS is essential.

7. Are CNTs Safe in End Products? (Batteries, Plastics, Coatings, Cement)

Yes. When CNTs are embedded in a solid matrix, exposure is extremely low.

Batteries

CNTs are integrated into electrode slurry and baked into a solid layer.

Coatings & Inks

CNTs are encapsulated in polymer binders.

Composites

CNTs are permanently locked within thermoplastics or thermosets.

Construction Materials

CNTs bond with cement hydration products.

There is no meaningful release under normal use.

8. CNT Safety Is Manageable With Proper Practices

Carbon nanotubes are safe to use in industrial and commercial applications when handled correctly. Modern CNT materials—short, purified, functionalized—have significantly improved safety profiles, and composite forms pose minimal risk. Environmental impacts are moderate and manageable with standard waste-handling procedures.

Key Takeaways

✔ CNT safety depends on form and exposure route

✔ Powders require engineering controls and PPE

✔ Dispersions, composites, films → very low risk

✔ CNTs are safe in end products (batteries, plastics, coatings)

✔ Regulatory frameworks are already well-established

✔ Environmental impact manageable with proper disposal

For manufacturers, establishing standard handling procedures not only ensures compliance but also increases customer confidence—especially in sectors like electronics, energy storage, automotive, construction, and advanced materials.