How to Select Conductive Additives for Polymer Processing

1. Introduction: Why Conductive Additives Matter

Conductive polymer composites are widely used in applications such as electromagnetic interference (EMI) shielding, electrostatic discharge (ESD) protection, sensors, heating elements, and flexible electronics. In most cases, the polymer matrix itself is electrically insulating, making conductive additives essential for achieving the required electrical functionality.

Selecting the right conductive additive is not simply a matter of achieving conductivity. It involves balancing electrical performance, mechanical properties, processability, cost, and long-term stability. This article provides a practical, engineering-oriented guide to selecting conductive additives for polymer processing.

2. Fundamental Concepts: Conductivity in Polymer Composites

Electrical conductivity in polymer composites is governed by the formation of a percolation network. When conductive fillers reach a critical volume fraction (percolation threshold), a continuous conductive pathway forms.

Key influencing factors include:

-

Filler shape and aspect ratio

-

Dispersion quality

-

Polymer–filler interaction

-

Processing method

Understanding these fundamentals is essential for rational material selection.

3. Common Types of Conductive Additives

3.1 Carbon Black

Carbon black is the most widely used conductive additive due to:

-

Low cost

-

Established supply chain

-

Good processability

However, it typically requires high loading levels, which can negatively impact mechanical properties and melt flow.

3.2 Carbon Nanotubes (CNTs)

CNTs offer:

-

Extremely low percolation thresholds

-

High conductivity at low loading

-

Minimal impact on mechanical properties

They are suitable for high-performance and lightweight applications but require careful dispersion control.

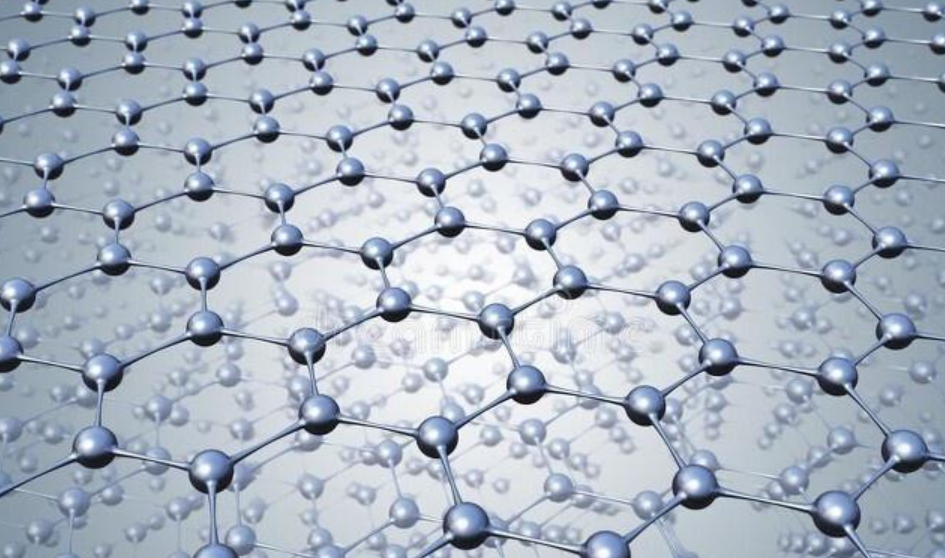

3.3 Graphene and Graphene Nanoplatelets (GNPs)

Graphene-based additives provide:

-

Good in-plane conductivity

-

Barrier and reinforcement effects

-

Tunable conductivity

They are often used in combination with other fillers.

3.4 Metal-Based Fillers

Metal powders and flakes (e.g., silver, copper, nickel) offer high conductivity but come with:

-

High density

-

Oxidation risk

-

Higher cost

They are mainly used where very low resistivity is required.

4. Key Selection Criteria

4.1 Target Electrical Performance

Define whether the application requires:

-

ESD protection

-

EMI shielding

-

Joule heating

-

Signal transmission

Each application has different conductivity requirements, influencing filler choice and loading.

4.2 Processing Method Compatibility

Conductive additives must be compatible with:

-

Injection molding

-

Extrusion

-

Blow molding

-

Compression molding

High-aspect-ratio fillers may increase viscosity and require processing optimization.

4.3 Dispersion and Compounding

Poor dispersion leads to:

-

Inconsistent conductivity

-

Mechanical weak points

-

Processing instability

Masterbatches and surface-treated additives are often used to improve dispersion.

4.4 Mechanical Property Retention

High filler loadings can reduce:

-

Impact strength

-

Elongation

-

Fatigue resistance

Low-loading additives like CNTs are preferred where mechanical integrity is critical.

5. CNTs as Advanced Conductive Additives

CNTs are increasingly adopted due to their ability to deliver conductivity at very low loading levels (typically <1 wt%).

Key benefits include:

-

Minimal effect on melt flow

-

Enhanced mechanical reinforcement

-

Stable conductivity under deformation

CNTs are especially effective in ESD, EMI shielding, and sensor applications.

6. Hybrid Filler Strategies

Combining different conductive additives can optimize performance:

-

CNT + carbon black: improved percolation and cost control

-

CNT + graphene: enhanced network connectivity

-

Carbon black + metal fillers: balanced conductivity and cost

Hybrid systems often outperform single-filler formulations.

7. Cost–Performance Optimization

While CNTs and graphene have higher unit costs, their low required loading often results in:

-

Lower total additive cost

-

Reduced material density

-

Improved product lifespan

Evaluating cost per performance, rather than cost per kilogram, is critical.

8. Application-Based Selection Guide

-

ESD packaging: Carbon black or CNT-based systems

-

EMI shielding housings: CNT or hybrid fillers

-

Heating elements: CNT or graphene-based networks

-

Sensors and smart parts: CNTs preferred

9. Processing and Quality Control Considerations

Key processing factors include:

-

Shear conditions during compounding

-

Thermal stability of additives

-

Reproducibility across batches

Quality control of conductive additives is essential for consistent performance.

Selecting conductive additives for polymer processing requires a holistic evaluation of electrical, mechanical, and processing requirements. While traditional fillers like carbon black remain widely used, advanced nanocarbon materials such as CNTs and graphene offer superior performance at lower loadings.

For applications demanding lightweight, durability, and reliable conductivity, CNT-based conductive additives provide a compelling solution.