CNT Masterbatch Design – Balancing Dispersion and Processability

1. Why CNT Masterbatch Matters

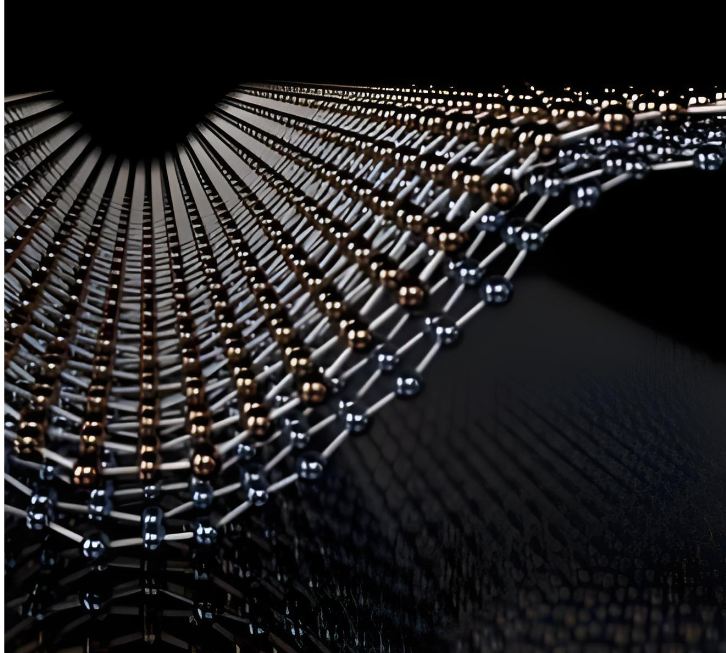

Carbon nanotubes (CNTs) offer outstanding electrical and mechanical properties, but their practical value is only realized through proper integration into polymer systems.

For most industrial users, CNT masterbatches represent the most reliable and scalable way to introduce CNTs into thermoplastics, enabling:

-

Safer handling

-

More consistent dispersion

-

Compatibility with existing processing lines

However, masterbatch design involves a critical trade-off:

maximizing CNT dispersion while maintaining acceptable melt processability.

2. What Is a CNT Masterbatch?

A CNT masterbatch is a highly concentrated CNT–polymer compound, later diluted into a target resin to reach the final CNT loading.

Its role is not to deliver final properties directly, but to act as a dispersion carrier that enables reproducible downstream processing.

3. Core Design Challenge: Dispersion vs Processability

CNT masterbatch performance depends on two competing factors:

-

Dispersion quality

-

Determines conductivity efficiency

-

Controls percolation behavior

-

-

Processability

-

Melt viscosity

-

Flow stability

-

Compatibility with extrusion and injection molding

-

Over-optimizing either side leads to practical problems.

4. CNT Dispersion Mechanisms in Masterbatches

Dispersion involves:

-

Agglomerate breakup

-

CNT distribution within the carrier resin

-

Partial network formation

However, excessive shear:

-

Shortens CNT effective length

-

Reduces aspect ratio

-

Can lower conductivity efficiency after dilution

Effective dispersion is therefore controlled, not maximized.

5. CNT Loading Level in Masterbatches

Higher CNT content improves dilution efficiency but introduces challenges:

| CNT Content | Effect |

|---|---|

| Low | Easy processing, larger dilution ratio |

| Medium | Balanced dispersion and flow |

| Very high | Severe viscosity increase, poor handling |

Industrial masterbatches typically aim for processable concentration windows, rather than theoretical maximum loading.

6. Carrier Resin Selection

The carrier resin plays a central role in masterbatch performance.

Key considerations:

-

Compatibility with target polymers

-

Melt viscosity and thermal stability

-

Polarity and CNT affinity

Common carrier systems include:

-

Polyolefins (PP, PE)

-

ABS

-

PA (nylon)

-

PC

Carrier mismatch often results in poor CNT re-dispersion after dilution.

7. Melt Rheology Control

CNTs strongly affect melt behavior:

-

Increased shear thinning

-

Elevated zero-shear viscosity

-

Narrower processing windows

Masterbatch formulation must ensure:

-

Stable feeding

-

Predictable pressure buildup

-

Compatibility with standard screw designs

Rheology control is as important as electrical performance.

8. Dilution Behavior and Network Reconstruction

After dilution:

-

CNTs must re-distribute into the final polymer

-

Conductive networks must re-form

A well-designed masterbatch allows:

-

Network reconstruction at low final CNT loading

-

Minimal conductivity loss after dilution

Poor masterbatch design leads to dispersion collapse during processing.

9. Comparison with Direct CNT Feeding

| Aspect | Direct Feeding | CNT Masterbatch |

|---|---|---|

| Handling safety | Low | High |

| Dispersion control | Difficult | Controlled |

| Process stability | Sensitive | Robust |

| Scale-up | Challenging | Industrially proven |

For most manufacturers, masterbatch-based CNT integration remains the preferred route.

10. Performance Metrics for CNT Masterbatches

Key evaluation parameters include:

-

Electrical resistivity after dilution

-

Melt flow index (MFI) impact

-

Mechanical property retention

-

Batch-to-batch consistency

Masterbatches should be evaluated in final formulations, not in isolation.

11. Application-Oriented Masterbatch Design

Different applications prioritize different balances:

-

ESD plastics → low CNT loading, high processability

-

EMI shielding → stable conductive networks

-

Structural conductive parts → mechanical reinforcement + conductivity

-

3D printing filaments → flow stability and nozzle reliability

There is no universal masterbatch solution.

12. Manufacturing and Scale-Up Considerations

Successful industrial masterbatch production requires:

-

Stable CNT supply and morphology control

-

Consistent compounding conditions

-

Inline quality monitoring

Scale-up challenges often arise from thermal history and shear sensitivity, not formulation chemistry.

13. Future Directions

-

Hybrid CNT–graphene masterbatches

-

Lower-viscosity carrier systems

-

Application-specific masterbatch grades

-

Improved dispersion diagnostics

CNT masterbatches are enablers, not end products.

Effective masterbatch design balances:

-

Sufficient CNT dispersion

-

Acceptable melt processability

-

Reliable dilution behavior

Rather than pushing CNT content to extremes, successful systems focus on controlled network formation within industrial processing limits.