CNT Conductive Path Formation – Percolation Theory Explained Simply

1. Why Conductive Path Formation Matters

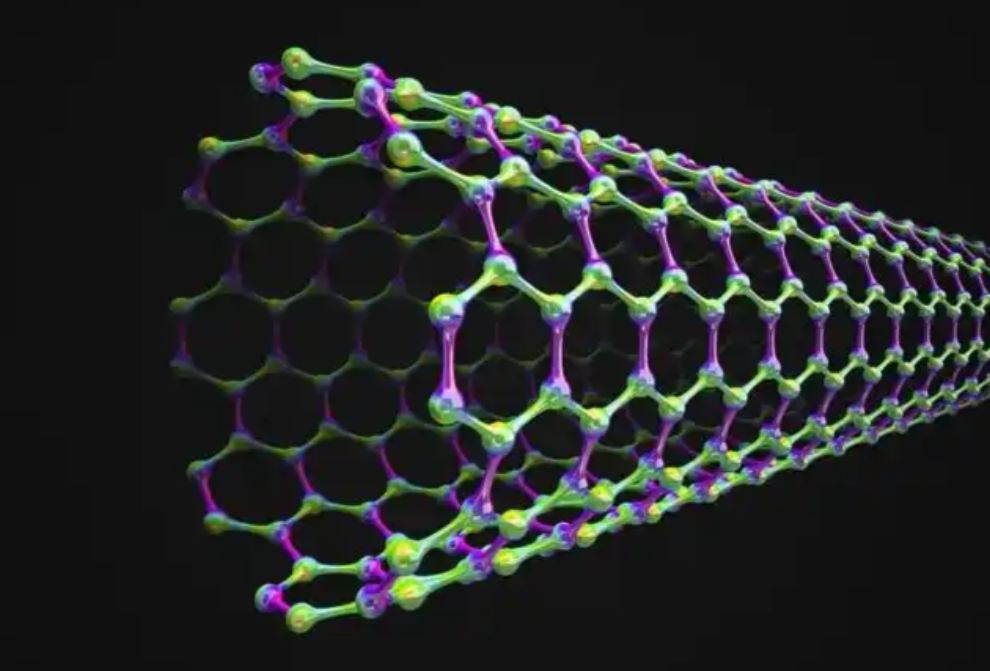

Carbon nanotubes (CNTs) are widely used to impart electrical conductivity to polymers, coatings, and composites. However, conductivity does not increase linearly with CNT content.

Instead, a critical concentration, known as the percolation threshold, determines when CNTs form a continuous conductive network across the material. Understanding this concept is essential for designing efficient, cost-effective, and processable conductive composites.

2. What Is Percolation Theory?

Percolation theory describes how randomly distributed conductive particles form a connected network in an insulating matrix.

Key points:

-

Below the threshold → CNTs are isolated → material remains insulating

-

At threshold → a few CNTs connect across the matrix → conductivity rises sharply

-

Above threshold → most CNTs contribute to network → conductivity saturates

This explains why a small increase in CNT content can cause orders-of-magnitude increase in conductivity.

3. CNT Network Formation: A Visual Analogy

Think of CNTs like roads on a map:

-

Sparse roads → isolated streets, no city-wide connectivity → electrons cannot travel

-

Critical density → highways connect neighborhoods → conductive path forms

-

Dense network → multiple interconnected highways → robust conductivity

CNT length, aspect ratio, and alignment all influence how easily these “roads” connect.

4. Factors Affecting CNT Percolation Threshold

-

Aspect Ratio (Length-to-Diameter)

-

Higher aspect ratio → lower percolation threshold

-

Long, thin CNTs bridge gaps more easily

-

-

Dispersion Quality

-

Well-dispersed CNTs → uniform network → predictable conductivity

-

Agglomerated CNTs → local clusters, isolated regions → higher threshold

-

-

Polymer Matrix and Viscosity

-

High-viscosity polymers → hinder CNT movement → require higher loading

-

Low-viscosity matrices → easier CNT network formation

-

-

Orientation / Alignment

-

Random orientation → isotropic conductivity

-

Partial alignment → directional conductivity, lower connectivity in some directions

-

5. CNT Loading vs Conductivity Curve

Typical behavior:

| CNT Content | Conductivity |

|---|---|

| Below percolation | Very low (insulating) |

| Around threshold | Sharp increase (semi-conductive) |

| Above threshold | Plateau (conductive network established) |

Implication: adding CNTs beyond the percolation threshold increases cost and viscosity but gives diminishing returns in conductivity.

6. Hybrid Networks for Lower Thresholds

Combining CNTs with other nanocarbon materials (e.g., graphene, carbon black) can:

-

Reduce percolation threshold

-

Improve conductivity uniformity

-

Enhance mechanical and thermal properties

Hybrid networks allow lower CNT loading while maintaining performance and processability.

7. Practical Guidelines for Engineers

-

Identify the target conductivity for your application (ESD, EMI, sensors).

-

Choose CNTs with sufficient aspect ratio and purity.

-

Ensure uniform dispersion using masterbatches, solvent-assisted mixing, or melt compounding.

-

Optimize loading to just above percolation to balance performance and processing.

8. Applications of Percolation-Controlled CNT Composites

-

Antistatic and ESD plastics → minimal CNT content to reduce cost

-

EMI shielding → higher CNT content to maximize network coverage

-

Conductive coatings and inks → fine-tuned CNT network ensures uniform conductivity

-

3D printing filaments → percolation ensures reliable layer-to-layer electron paths

Percolation theory explains the sudden onset of conductivity in CNT composites. For engineers and formulators:

-

Network formation, not absolute CNT content, governs performance

-

Aspect ratio, dispersion, and hybrid strategies can reduce required CNT loading

-

Understanding percolation allows cost-effective and process-friendly design of conductive materials

Mastering this concept is a prerequisite for developing high-performance CNT composites across plastics, coatings, and inks.