CNT vs. Graphene for Thermal Management

Strengths, Limitations, and Practical Design Trade-Offs

Why the Choice Is Not Obvious

Carbon nanotubes (CNTs) and graphene are often grouped together as “high thermal conductivity nanomaterials.”

In practice, however, they solve thermal problems in very different ways.

Selecting the wrong material—or treating them as interchangeable—often leads to:

-

Overdesigned formulations

-

Unstable thermal performance

-

Unnecessary cost increases

This article compares CNTs and graphene from a thermal system design perspective, focusing on strengths, limitations, and application-driven choices.

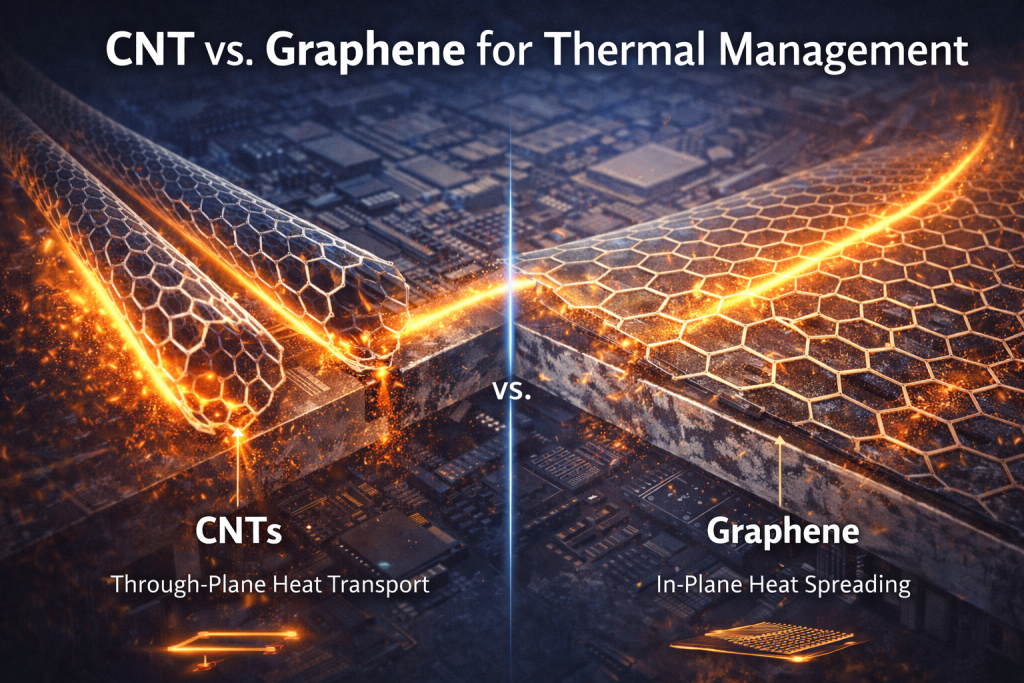

Fundamental Difference: Dimensionality Drives Thermal Behavior

The most important distinction lies in material dimensionality.

-

CNTs are one-dimensional conductors

-

Graphene is a two-dimensional heat spreader

This single difference defines how heat moves through each material system.

CNTs for Thermal Management

Core Strengths of CNTs

1. Excellent Through-Plane Heat Transport

CNTs conduct heat extremely efficiently along their axial direction, making them ideal for:

-

Bridging thermal interfaces

-

Enhancing vertical heat flow

-

Connecting heat sources to substrates or heat sinks

This makes CNTs particularly effective in:

-

Thermal interface materials (TIMs)

-

Bulk composites

-

Thick coatings or molded parts

2. Low Percolation Threshold

Due to their high aspect ratio, CNTs form continuous thermal networks at very low loading levels, often below 1 wt%.

Benefits include:

-

Minimal impact on viscosity

-

Preserved mechanical flexibility

-

Easier processing in polymers and coatings

3. Mechanical Reinforcement Synergy

CNTs also improve:

-

Crack resistance

-

Fatigue durability

-

Thermal cycling stability

This is especially valuable in systems exposed to vibration or repeated heating–cooling cycles.

Limitations of CNTs

-

Junction thermal resistance between tubes can limit performance

-

Random CNT networks offer limited in-plane heat spreading

-

Agglomeration risks if dispersion is poorly controlled

-

Cost sensitivity at high purity or alignment requirements

CNTs excel at connecting, but are less efficient at spreading heat laterally.

Graphene for Thermal Management

Core Strengths of Graphene

1. Outstanding In-Plane Heat Spreading

Graphene is one of the most effective lateral heat spreaders available.

This makes it ideal for:

-

Thin films

-

Thermal coatings

-

Surface heat dissipation layers

-

Hot-spot reduction

Graphene distributes heat rapidly across surfaces, creating more uniform temperature profiles.

2. High Thermal Performance in Thin Layers

Graphene retains strong thermal performance even in:

-

Micron-scale coatings

-

Lightweight films

-

Space-constrained electronics

This is a major advantage over conventional fillers, which require thick layers to be effective.

3. Barrier and Stability Benefits

In addition to thermal performance, graphene:

-

Improves barrier properties

-

Enhances chemical resistance

-

Reduces moisture and oxygen diffusion

These secondary benefits are valuable in harsh environments.

Limitations of Graphene

-

Through-plane thermal conductivity is limited by interlayer resistance

-

Large sheets are difficult to disperse uniformly

-

High loadings can increase viscosity sharply

-

Performance is highly orientation-dependent

Graphene spreads heat well in-plane, but struggles to move heat across thickness.

Direct Comparison: CNT vs Graphene

| Parameter | CNT | Graphene |

|---|---|---|

| Dimensionality | 1D | 2D |

| Best Thermal Direction | Through-plane | In-plane |

| Network Formation | Easy at low loading | Requires orientation control |

| Thin-Film Performance | Moderate | Excellent |

| Interface Bridging | Excellent | Limited |

| Dispersion Sensitivity | High | Very high |

| Cost Sensitivity | Medium | Medium–High |

Why Hybrid CNT–Graphene Systems Are Increasingly Used

In real thermal systems, heat must:

-

Leave the heat source

-

Cross interfaces

-

Spread across surfaces

-

Dissipate into the environment

No single material handles all four steps optimally.

Hybrid CNT–graphene networks combine:

-

CNTs for vertical heat transport and interfacial bridging

-

Graphene for lateral heat spreading and surface dissipation

The result is a balanced thermal architecture, not just higher conductivity numbers.

Application-Based Selection Guide

Choose CNTs when:

-

Through-plane heat transfer dominates

-

Interface resistance is critical

-

Bulk composites or TIMs are used

-

Mechanical reinforcement is needed

Choose Graphene when:

-

Surface heat spreading is required

-

Coatings or thin films are used

-

Hot-spot reduction is critical

-

Weight and thickness must be minimized

Choose Hybrid CNT–Graphene Systems when:

-

Both interface transfer and surface spreading matter

-

Performance stability over time is required

-

Space and weight constraints are tight

-

Multifunctional properties are desired

Processing and Scale-Up Considerations

At industrial scale, performance is often limited by:

-

Dispersion quality

-

Mixing energy

-

Compatibility with existing equipment

Hybrid systems often allow lower total filler loading, improving processability and cost control.

Testing: Avoiding Misleading Comparisons

Thermal performance should always be evaluated under:

-

Real thickness conditions

-

Direction-specific measurements

-

Relevant interface pressures

-

Long-term thermal cycling

Comparing CNT and graphene using only bulk conductivity values often leads to incorrect conclusions.

Function Over Labels

CNTs and graphene are not competitors—they are thermal tools with different roles.

-

CNTs connect and transport heat across interfaces

-

Graphene spreads and stabilizes heat across surfaces

Understanding their strengths and limitations allows engineers to design lighter, thinner, and more reliable thermal management systems.

In many advanced applications, the best solution is not CNT or graphene—but a carefully engineered combination of both.