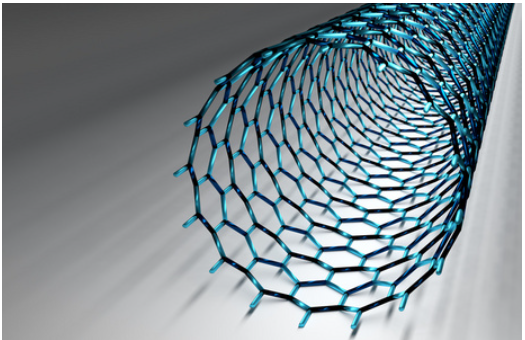

Carbon Nanotube Composites: Lightweight Strength for Aerospace and Automotive Innovatio

Introduction: Lighter, Stronger, Smarter Materials

Weight reduction is critical in industries like aviation and EVs. Less mass means better fuel economy, longer battery life, and lower emissions. Carbon Nanotube-reinforced composites offer unparalleled strength-to-weight ratios, making them ideal candidates for structural components.

Why CNTs Work So Well

CNTs add mechanical reinforcement, electrical conductivity, and thermal stability to base materials such as:

-

Epoxy resins

-

Thermoplastics (e.g., PEEK, Nylon)

-

Ceramics

-

Metals (Aluminum, Magnesium)

Even small quantities (0.5–2 wt%) can double or triple tensile strength while reducing material weight.

Key Advantages

| Feature | CNT Composites | Traditional Composites |

|---|---|---|

| Strength-to-Weight Ratio | Ultra-high | Medium |

| Electrical Conductivity | Excellent | Poor (non-metallic) |

| Thermal Management | High | Low to moderate |

| Fatigue Resistance | Excellent | Variable |

Aerospace Applications

-

Structural Panels: Fuselage, wings, interior shells

-

EMI Shielding: Protect sensitive avionics systems

-

De-Icing Systems: CNTs used as Joule heaters on aircraft surfaces

Automotive Applications

-

EV Battery Casings: Strong, conductive, and thermally stable

-

Lightweight Chassis Components: Improves energy efficiency

-

Sensor-Embedded Parts: Enables smart diagnostics in real-time

Industry Momentum

Boeing, Airbus, and Tesla have all initiated CNT composite pilot programs. With increasing material availability and falling cost, CNTs are entering commercial-grade applications more rapidly than ever before.

Summary: CNT Composites Enable the Next Leap

Whether it’s the sky or the road, carbon nanotube-reinforced materials are pushing the boundaries of performance, safety, and sustainability. Their ability to do more with less weight will define the