Carbon Nanotube Price Trends and Influencing Factors: A Cost Analysis from Raw Materials to End-Use Applications

Introduction

The pricing of carbon nanotubes (CNTs) plays a crucial role in their adoption across various industries, including energy storage, electronics, aerospace, and advanced manufacturing. As the demand for CNTs continues to rise, understanding the factors influencing their cost from raw material procurement to end-use applications becomes essential. This article explores the price trends of CNTs, analyzing the key factors that contribute to their cost structure and how they affect the final product price.

1. Raw Material Costs and Production Methods

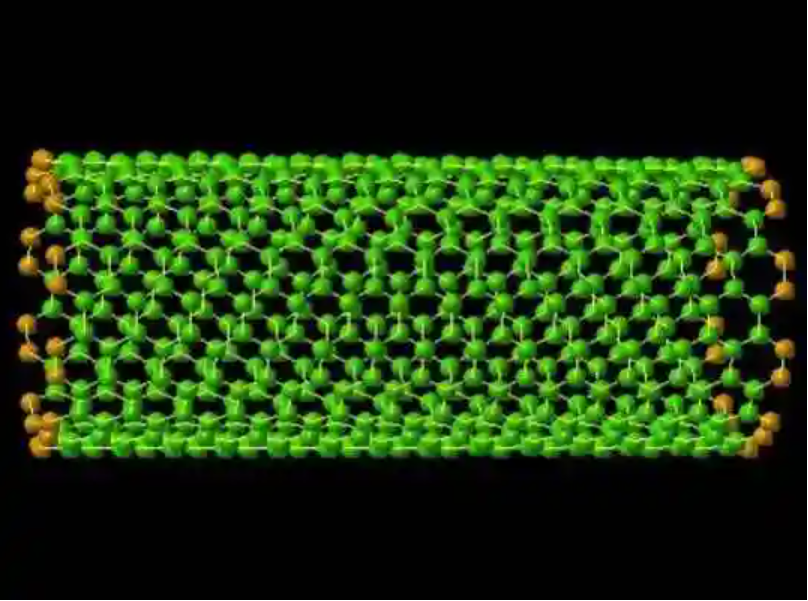

The production of CNTs relies on specific raw materials and methods that significantly impact the final cost. The main production techniques—chemical vapor deposition (CVD), arc discharge, and laser ablation—each have different material and energy requirements.

Influencing Factors:

- Feedstock Prices: Carbon-based feedstocks, such as methane, acetylene, and carbon monoxide, are crucial to CNT production. Fluctuations in the prices of these hydrocarbons can lead to changes in production costs.

- Catalyst Costs: Catalysts like iron, cobalt, and nickel are essential for CNT growth. The price of these metals can vary due to global supply and demand, mining activities, and geopolitical factors, thereby impacting CNT production costs.

Impact on Price Trends:

- Feedstock and Catalyst Price Volatility: As demand for CNTs rises, raw material costs can be subject to volatility. Limited access to certain feedstocks and catalysts can also increase the price of CNTs.

- Environmental Regulations: Restrictions on mining activities and stricter environmental regulations can raise the cost of raw materials, especially in regions where natural resources are scarce.

2. Manufacturing Process and Yield

The method used to produce CNTs and the yield achieved are pivotal in determining the overall cost of production. Different techniques offer varying levels of quality, cost, and scalability.

Manufacturing Methods:

- CVD (Chemical Vapor Deposition): CVD is the most commonly used method for CNT production. It allows for scalable, high-quality production but requires significant energy input. While CVD production can be expensive due to energy costs, it remains the preferred method for large-scale production.

- Arc Discharge: This technique, typically used for single-wall CNTs (SWCNTs), requires high energy and specialized equipment, making it more costly than CVD. It is suitable for niche applications where high purity is required.

- Laser Ablation: Known for producing high-purity CNTs, this method is more expensive due to the need for specialized equipment and precise control.

Yield and Purity:

- High yields typically lower the cost per unit of CNTs, but producing high-purity CNTs (especially single-wall CNTs) is more challenging and costly.

- Single-wall CNTs (SWCNTs) typically command higher prices than multi-wall CNTs (MWCNTs) due to their purity and specific applications.

Impact on Price Trends:

- Advances in production technology, particularly in CVD, have led to improvements in yield and efficiency, gradually reducing costs over time.

- However, high-quality CNTs, especially SWCNTs, remain expensive due to the technical challenges involved in their production.

3. Technological Advancements and Innovation

Ongoing research and innovation in CNT production technologies continue to influence pricing trends. More efficient production methods and the development of automated processes have led to cost reductions in recent years.

Technological Developments:

- Improved Efficiency in Production: New catalysts, better control of reaction conditions, and more efficient reactor designs have helped increase the yield and reduce the cost of CNTs. The use of cheaper, abundant feedstocks and advanced deposition techniques can lower energy consumption and increase cost-effectiveness.

- Automation and Scaling: Automation in manufacturing processes has reduced labor costs and improved consistency, which also contributes to lower prices as production volumes rise.

Impact on Price Trends:

- Technological advancements in CNT production will likely lead to a decrease in prices over time, particularly as economies of scale come into play.

- The widespread adoption of newer manufacturing technologies can lower production costs and make CNTs more accessible to a broader range of industries.

4. Market Demand and End-Use Applications

Demand for CNTs is driven by their applications in energy storage, electronics, aerospace, and other advanced sectors. As the applications for CNTs grow, so does the pressure on pricing, especially for high-performance grades.

Key Applications and Price Impact:

- Energy Storage (Batteries): The demand for CNTs in lithium-ion batteries, especially for electric vehicles (EVs) and renewable energy storage, has been a key driver of price increases. High-performance CNTs are essential for improving the energy density and longevity of batteries.

- Electronics and Semiconductors: CNTs are used in flexible electronics, displays, and sensors, where their unique electrical properties provide advantages over traditional materials. These high-tech applications often require high-purity CNTs, which come at a premium.

- Aerospace and Defense: In these industries, CNTs are used for lightweight, high-strength materials. The need for specialized, high-performance CNTs for aerospace and defense applications pushes prices higher.

Impact on Price Trends:

- As the demand for CNTs in high-growth sectors such as energy storage and electronics continues to increase, prices are expected to rise, particularly for high-quality CNTs.

- However, as more manufacturers enter the market and production processes become more efficient, competition may lead to price stabilization or reductions over time.

5. Global Economic Factors

Global economic conditions play a crucial role in determining the price of CNTs. Raw material costs, geopolitical factors, and supply chain dynamics are all influenced by broader economic trends.

Influencing Factors:

- Oil and Gas Prices: Since CNTs are often produced using carbon-based feedstocks, fluctuations in oil and gas prices directly affect production costs.

- Geopolitical Factors: Trade tensions, tariffs, and sanctions can disrupt global supply chains, leading to price volatility in CNTs. Political instability in key regions that produce raw materials for CNT production can also impact availability and prices.

- Supply Chain Disruptions: Events such as the COVID-19 pandemic have demonstrated the fragility of global supply chains. Disruptions in the availability of raw materials or labor can lead to price increases.

Impact on Price Trends:

- Global economic uncertainty and geopolitical instability can create volatility in the CNT market. Fluctuations in raw material costs and supply chain issues may result in price hikes.

- Long-term economic growth and stabilization could lead to more predictable pricing trends, with potential reductions in prices as global supply chains stabilize and manufacturing processes become more efficient.

Conclusion

The price of carbon nanotubes is influenced by a complex mix of factors, including raw material costs, manufacturing methods, technological advancements, and global economic conditions. As demand for CNTs continues to increase in various industries, particularly in energy storage, electronics, and aerospace, prices are expected to rise, especially for high-performance CNTs. However, innovations in manufacturing processes, along with larger-scale production, may help reduce costs over time, making CNTs more accessible to a broader range of industries.