CNT–Graphene Hybrid Composites – Synergistic Effects

Why Combining 1D CNTs and 2D Graphene Unlocks Superior Material Performance

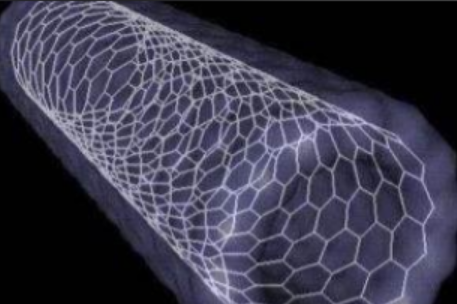

Carbon nanotubes (CNTs) and graphene are two of the most important carbon nanomaterials developed in recent decades. Individually, each material offers outstanding electrical, thermal, and mechanical properties. However, when CNTs and graphene are combined into hybrid composites, their synergistic effects often outperform either material alone.

This synergy arises from the complementary geometry of 1D CNTs and 2D graphene sheets, enabling the formation of efficient three-dimensional conductive networks. As a result, CNT–graphene hybrid composites are increasingly adopted in conductive coatings, energy storage, EMI shielding, sensors, and structural composites.

This article explains the origin of these synergistic effects, common fabrication strategies, performance advantages, and key industrial applications.

1. Why Combine CNTs and Graphene?

Although CNTs and graphene share similar carbon-based structures, they exhibit distinct strengths and weaknesses when used independently.

1.1 Limitations of CNT-Only Systems

-

CNTs tend to entangle and agglomerate

-

High viscosity at moderate loading levels

-

Conductive networks may be discontinuous at low content

1.2 Limitations of Graphene-Only Systems

-

Graphene sheets tend to restack

-

Contact resistance between sheets

-

Limited through-thickness conductivity

1.3 Complementary Geometries

-

CNTs (1D) act as conductive bridges between graphene sheets

-

Graphene (2D) provides large-area conductive platforms

-

Together, they form a 3D interconnected network

This structural complementarity is the foundation of CNT–graphene synergy.

2. Mechanisms Behind Synergistic Effects

2.1 Enhanced Electrical Conductivity

CNTs connect adjacent graphene sheets, reducing:

-

Junction resistance

-

Percolation threshold

-

Electron tunneling distance

As a result, hybrid systems often achieve the same conductivity as single-filler systems at 30–60% lower total loading.

2.2 Improved Mechanical Reinforcement

-

Graphene enhances in-plane stiffness

-

CNTs improve load transfer and crack bridging

-

CNTs prevent graphene restacking under stress

This leads to higher tensile strength, fracture toughness, and fatigue resistance.

2.3 Superior Thermal Transport

Graphene provides excellent in-plane heat spreading, while CNTs enable vertical heat conduction, improving overall thermal conductivity in polymer matrices and coatings.

2.4 Stability Under Deformation

Hybrid networks maintain conductivity under:

-

Bending

-

Stretching

-

Compression

-

Thermal cycling

This is essential for flexible electronics and wearable devices.

3. Fabrication Strategies for CNT–Graphene Hybrid Composites

3.1 Solution-Based Mixing

CNTs and graphene (or GO) are dispersed together in a solvent.

Key considerations:

-

Dispersion stability

-

Surfactant compatibility

-

Ultrasonic energy control

Used widely for inks, coatings, and films.

3.2 In-Situ Growth

CNTs are grown directly on graphene sheets via CVD.

Advantages:

-

Strong interfacial bonding

-

Highly interconnected networks

Limitations:

-

Higher cost

-

More complex processing

Used in high-performance electrodes and catalysts.

3.3 Layer-by-Layer Assembly

Alternating CNT and graphene layers form controlled architectures.

Benefits:

-

Precise thickness control

-

Tunable anisotropy

Common in transparent conductive films and sensors.

3.4 Polymer Composite Processing

Hybrid fillers are incorporated into:

-

Thermoplastics (PP, ABS, PC)

-

Thermosets (epoxy, PU)

-

Elastomers (silicone, rubber)

Processing methods:

-

Melt compounding

-

Solution casting

-

In-situ polymerization

4. Performance Advantages vs Single-Filler Systems

| Property | CNT Only | Graphene Only | CNT–Graphene Hybrid |

|---|---|---|---|

| Percolation threshold | Medium | Low | Very low |

| Conductivity stability | Moderate | Moderate | High |

| Mechanical toughness | Good | High | Very high |

| Dispersion stability | Challenging | Moderate | Improved |

| Deformation resistance | Limited | Limited | Excellent |

5. Key Industrial Applications

5.1 EMI Shielding Materials

Hybrid composites achieve shielding effectiveness of:

-

30–80 dB (depending on thickness and loading)

Used in:

-

EV battery enclosures

-

5G device housings

-

Aerospace electronics

-

Industrial control cabinets

Advantages:

-

Lightweight

-

Thin coatings

-

Broadband shielding

5.2 Conductive Coatings and Paints

CNT–graphene hybrids offer:

-

Stable antistatic performance

-

Improved adhesion

-

Lower filler content

Applications:

-

ESD floors

-

Electronics housings

-

Fuel tanks

-

Chemical containers

5.3 Energy Storage Devices

In electrodes for:

-

Supercapacitors

-

Lithium-ion batteries

-

Sodium-ion batteries

Benefits:

-

Faster electron transport

-

Improved ion accessibility

-

Longer cycle life

5.4 Flexible and Wearable Electronics

Hybrid networks maintain conductivity under repeated deformation.

Used in:

-

Stretchable sensors

-

Wearable heaters

-

Flexible circuits

-

Smart textiles

5.5 Structural and Multifunctional Composites

CNT–graphene hybrids enhance:

-

Mechanical strength

-

Electrical conductivity

-

Damage sensing capability

Used in:

-

Aerospace composites

-

Automotive parts

-

Wind energy components

6. Challenges and Design Considerations

6.1 Dispersion Control

Poor dispersion negates synergy.

Solutions:

-

Surface functionalization

-

Masterbatch approaches

-

Optimized mixing sequences

6.2 Ratio Optimization

Typical CNT:graphene ratios range from 1:1 to 1:5 depending on application.

Overloading CNTs increases viscosity; excess graphene causes restacking.

6.3 Cost vs Performance Balance

Hybrid systems reduce total filler loading, helping offset material cost.

7. Market Trends and Future Outlook

-

Rapid growth in EV and 5G-related EMI shielding

-

Increasing adoption in conductive plastics

-

Hybrid fillers becoming standard in advanced formulations

-

Continued development of water-based and eco-friendly systems

CNT–graphene hybrid composites are transitioning from research materials to industrial-standard solutions.

CNT–graphene hybrid composites represent one of the most effective strategies for maximizing the performance of carbon nanomaterials. By combining 1D CNTs and 2D graphene, these composites overcome the limitations of each individual filler, delivering superior conductivity, mechanical robustness, and stability.

As processing technologies mature and costs continue to decrease, CNT–graphene hybrid materials are set to play a critical role in next-generation electronics, energy systems, and advanced composites.