CNT vs Carbon Black in Conductive Plastics

A Practical Comparison Based on Percolation Behavior

Why Percolation Matters More Than Conductivity Numbers

When selecting conductive additives for plastics, many discussions focus on bulk conductivity values or price per kilogram.

In real polymer processing, however, the percolation threshold is often the most decisive factor.

Percolation determines:

-

How much additive is actually required

-

How much mechanical property loss occurs

-

Whether the material remains processable at scale

This article compares Carbon Nanotubes (CNTs) and Carbon Black (CB) from a practical percolation perspective, helping engineers choose the right solution for conductive plastics.

What Is Percolation in Conductive Plastics?

Percolation refers to the point at which conductive particles form a continuous electrical network within an insulating polymer matrix.

Below this threshold:

-

The material behaves as an insulator

Above it: -

Conductivity increases rapidly with small additive increments

The shape, aspect ratio, and dispersion of conductive fillers strongly influence where this threshold occurs.

Carbon Black: Spherical Particles, Higher Percolation

Carbon Black consists of quasi-spherical particles forming aggregates.

Typical characteristics:

-

Percolation threshold: 10–20 wt% (depending on grade and polymer)

-

Conductivity achieved through particle-to-particle contact

-

Requires high loading to form continuous pathways

Practical consequences:

-

Significant increase in viscosity

-

Loss of impact strength and elongation

-

Reduced surface quality (flow marks, roughness)

-

Heavier parts and higher filler content overall

Carbon Black remains attractive for:

-

Cost-sensitive applications

-

Antistatic rather than EMI or shielding-level conductivity

-

Thick-walled or compression-molded parts

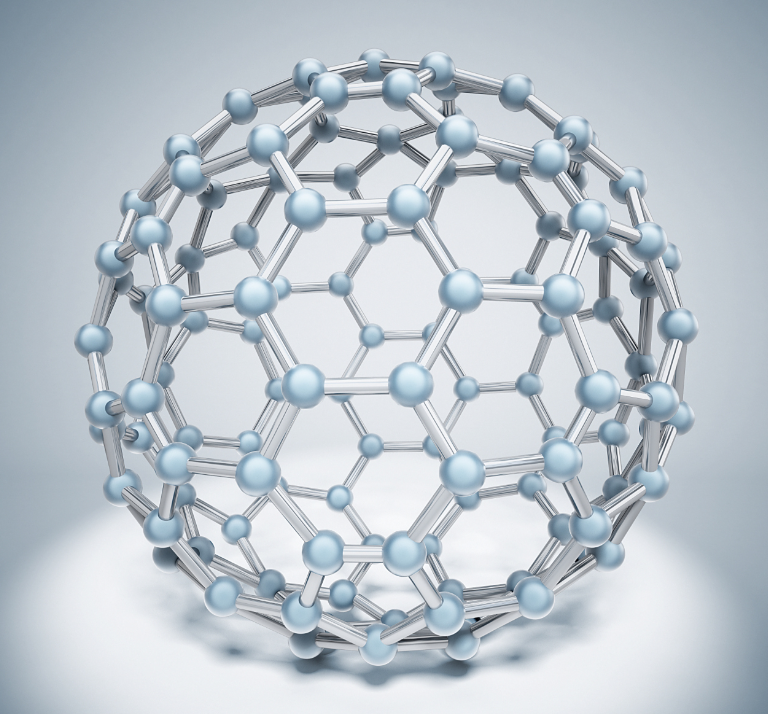

CNTs: High Aspect Ratio, Low Percolation

Carbon Nanotubes are one-dimensional nanomaterials with extremely high aspect ratios (length-to-diameter).

Typical characteristics:

-

Percolation threshold: 0.1–1 wt%

-

Network formation through entanglement rather than simple contact

-

Conductive paths form earlier and more efficiently

Practical advantages:

-

Much lower additive loading

-

Retained mechanical properties

-

Minimal density increase

-

Better surface finish

-

Stable conductivity under strain or vibration

CNTs are especially suited for:

-

Injection molding

-

Thin-wall components

-

Lightweight designs

-

EMI shielding plastics

-

High-performance ESD materials

Side-by-Side: Practical Percolation Comparison

| Parameter | Carbon Black | CNT |

|---|---|---|

| Typical Percolation Threshold | 10–20 wt% | 0.1–1 wt% |

| Aspect Ratio | Low | Very high |

| Conductive Network | Particle contact | Entangled network |

| Effect on Melt Flow | Strong negative | Mild |

| Mechanical Property Retention | Poor at high loading | Good |

| Surface Quality | Often degraded | Generally smooth |

| Cost per kg | Low | Higher |

| Cost per functional part | Often higher | Often lower |

Cost Reality: Per Kilogram vs Per Part

While CNTs are more expensive per kilogram, percolation behavior changes the real cost calculation.

In many conductive plastic formulations:

-

15 wt% Carbon Black may be required

-

0.5 wt% CNT may achieve the same conductivity

When accounting for:

-

Lower filler usage

-

Easier processing

-

Lower scrap rate

-

Improved part performance

CNT-based systems often deliver better cost-performance balance at the component level.

Hybrid Systems: When CNT and Carbon Black Work Together

In practice, many manufacturers adopt CNT + Carbon Black hybrid formulations to balance cost and performance.

Typical strategy:

-

Carbon Black provides baseline conductivity

-

CNT bridges gaps and lowers percolation threshold

-

Total filler loading is reduced

Hybrid systems are increasingly used in:

-

Automotive interiors

-

Battery housings

-

Industrial enclosures

-

Consumer electronics casings

Application-Oriented Selection Guide

Choose Carbon Black when:

-

Conductivity requirements are low (antistatic)

-

Part thickness is high

-

Cost pressure dominates

-

Mechanical performance is secondary

Choose CNTs when:

-

Low percolation is critical

-

Lightweighting matters

-

Mechanical integrity must be preserved

-

EMI shielding or stable ESD performance is required

Choose Hybrid Systems when:

-

You want to optimize cost without sacrificing processability

-

Existing CB formulations need performance upgrades

-

You need tuning flexibility across product lines

Percolation is not just a theoretical concept—it directly defines:

-

Processing stability

-

Material performance

-

Total system cost

Understanding how CNTs and Carbon Black form conductive networks differently allows engineers to move beyond material price comparisons and toward true application-driven material selection.

As conductive plastics evolve toward lighter, thinner, and more functional designs, percolation efficiency increasingly determines success.