CNTs for EMI Shielding – Design, Testing, and Performance

In the era of high-speed electronics and wireless communication, electromagnetic interference (EMI) has become a serious challenge. From industrial automation to electric vehicles and 5G communication systems, sensitive electronic components are easily affected by unwanted electromagnetic noise. Effective EMI shielding materials are therefore critical to ensure device reliability, safety, and signal integrity.

Traditionally, metals such as copper or aluminum have been used as EMI shields. However, these materials are heavy, prone to corrosion, and less suitable for flexible or lightweight electronic designs. This is where carbon nanotubes (CNTs) come into play — offering lightweight, flexible, and high-performance EMI shielding alternatives.

This article explores how CNT-based materials are designed and tested for EMI shielding, and how they outperform conventional materials in various industrial and electronic applications.

1. What Is EMI Shielding and Why Is It Needed?

Electromagnetic interference (EMI) refers to unwanted electromagnetic signals that disrupt or degrade the operation of nearby electronic devices. These signals can be radiated (through air) or conducted (through wires), and their effects can range from noise and malfunction to complete failure.

EMI shielding works by either:

-

Reflecting electromagnetic waves (using conductive surfaces),

-

Absorbing them (by converting EM energy into heat),

-

Or a combination of both.

As electronics become more compact and operate at higher frequencies, the demand for lightweight, corrosion-resistant, and flexible EMI shielding materials has grown — and CNTs (carbon nanotubes) are among the most promising candidates.

2. Why CNTs Are Effective for EMI Shielding

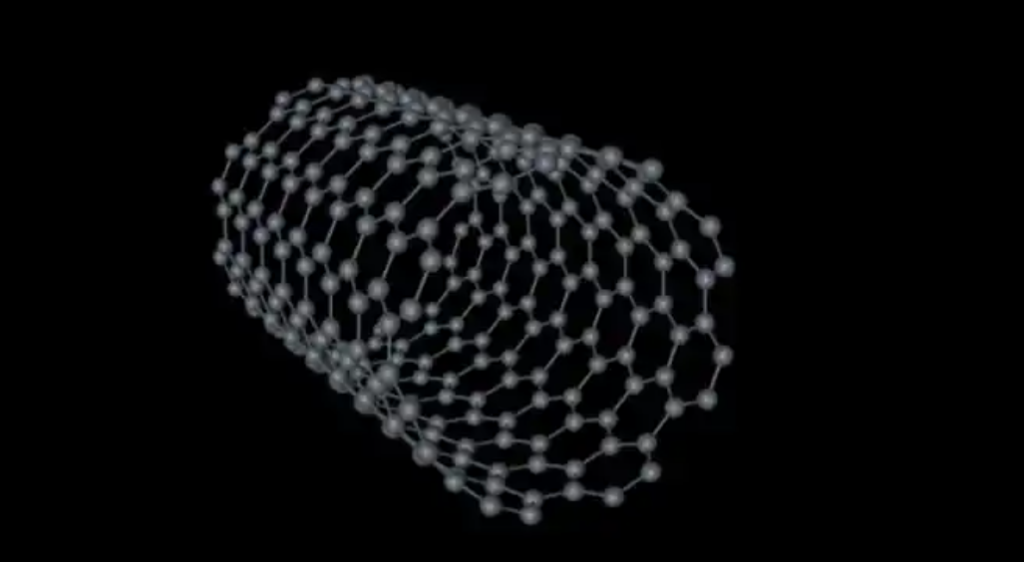

CNTs are nanoscale cylindrical structures made of carbon atoms arranged in hexagonal lattices. Their unique electrical, mechanical, and structural properties make them exceptional for EMI shielding applications.

2.1 High Electrical Conductivity

CNTs form continuous, percolating conductive networks within composites, allowing free electron movement. This conductivity enables effective reflection of electromagnetic waves — similar to metals, but at a fraction of the weight.

2.2 Intrinsic Absorption Capability

Beyond reflection, CNTs also contribute to EM absorption. Their nanostructured surfaces create multiple scattering paths and polarization sites, converting electromagnetic energy into heat. This dual behavior (reflection + absorption) enhances total shielding effectiveness.

2.3 Lightweight and Corrosion-Resistant

CNT-based composites are up to 90% lighter than metallic counterparts. They are also chemically stable, non-corrosive, and compatible with polymers — ideal for aerospace, automotive, and flexible electronics applications.

2.4 Tunable Shielding Properties

By adjusting CNT loading, dispersion, and orientation, engineers can tailor conductivity and shielding effectiveness (SE) for specific frequency ranges — from low-frequency industrial signals to GHz-level communication systems.

3. EMI Shielding Design with CNT Composites

CNTs are rarely used in isolation; they are typically embedded in polymer or resin matrices to create conductive composites. The design of such composites directly affects EMI performance.

3.1 Conductive Network Formation

The most critical design factor is achieving a percolation network — where CNTs form continuous conductive paths throughout the matrix.

-

The percolation threshold is the minimum CNT content required to achieve electrical connectivity.

-

For high-aspect-ratio CNTs, this threshold can be as low as 0.1–1 wt%, meaning only a small amount of CNTs is needed to impart conductivity.

3.2 Polymer Matrix Selection

CNTs can be dispersed in a wide range of matrices:

-

Thermoplastics: ABS, PP, PC — used for automotive housings.

-

Thermosets: Epoxy, PU — used for coatings and structural parts.

-

Elastomers: Silicone, TPU — used for flexible electronics and gaskets.

The matrix affects not only mechanical flexibility but also frequency-dependent EMI behavior.

3.3 Orientation and Alignment

CNT alignment can enhance shielding in specific directions. For instance:

-

Random orientation → isotropic shielding.

-

Aligned CNTs → stronger directional conductivity, useful for specific design requirements.

3.4 Hybrid Compositions

CNTs are often combined with other conductive fillers (graphene, carbon black, or metallic flakes) to balance performance and cost.

This synergy improves both low-frequency conductivity and high-frequency absorption.

4. Measuring and Testing EMI Shielding Performance

Evaluating EMI shielding involves standardized test methods that measure how much electromagnetic energy is blocked, absorbed, or transmitted through a material.

4.1 Shielding Effectiveness (SE, dB)

The most important parameter for EMI shielding is Shielding Effectiveness (SE), expressed in decibels (dB):

SE (dB) = 10 log(P₁ / P₂)

where P₁ is the incident power and P₂ is the transmitted power.

A higher SE value means better shielding performance.

| SE (dB) | Effectiveness | Typical Use |

|---|---|---|

| 20–40 dB | Moderate | Consumer electronics casings |

| 40–60 dB | Good | Automotive & industrial electronics |

| >60 dB | Excellent | Aerospace & defense systems |

CNT composites can achieve 40–70 dB SE at relatively low thicknesses (~1 mm), rivaling metal foils.

4.2 Frequency Range Testing

EMI testing typically covers frequencies from 30 MHz to 1.5 GHz (for general electronics) or up to 18 GHz for high-frequency applications like radar or 5G systems.

CNT composites maintain stable shielding across a wide frequency band, unlike metal meshes that may resonate and lose performance at high frequencies.

4.3 Testing Methods

Common international testing standards include:

-

ASTM D4935 – Coaxial transmission line method.

-

IEEE Std 299 – Shielding effectiveness of enclosures.

-

MIL-STD-285 – Military standard for EM attenuation testing.

These tests measure reflection, absorption, and transmission coefficients to calculate overall SE.

5. Performance Factors and Optimization

CNT-based EMI materials can be optimized through processing, structure control, and formulation tuning.

5.1 CNT Loading Content

Increasing CNT content enhances conductivity and SE — but excessive CNTs may increase brittleness and cost.

Typical loadings range between 1–10 wt%, depending on matrix type and target application.

5.2 Dispersion Quality

Uniform dispersion ensures consistent electrical networks and stable performance.

High-shear mixing, ultrasonication, or surface functionalization of CNTs can improve dispersion and interfacial bonding with polymers.

5.3 Film Thickness

Thicker films generally improve shielding but add weight. For lightweight designs, multi-layer structures or CNT-coated fabrics can provide high SE with minimal thickness (<200 μm).

5.4 Hybridization

Combining CNTs with graphene, MXene, or metal flakes can yield synergistic improvements in both reflection and absorption performance, especially in high-frequency regimes.

6. Applications of CNT-Based EMI Shielding Materials

CNT composites are now being applied in multiple industries that require lightweight and reliable EMI protection.

-

Automotive electronics: Shielding ECUs, battery management systems, and infotainment units.

-

Aerospace and defense: Lightweight shielding for aircraft structures and communication modules.

-

Consumer electronics: Protective layers for smartphones, laptops, and flexible displays.

-

Energy storage and power systems: EMI control in BMS, inverters, and high-voltage cables.

-

Medical devices: Prevent interference in wearable and implantable electronics.

7. Comparison: CNT vs. Metal-Based Shielding

| Property | CNT-Based Composites | Metal Foils |

|---|---|---|

| Weight | Very light | Heavy |

| Flexibility | Excellent | Poor |

| Corrosion resistance | Excellent | Prone to corrosion |

| Processing | Easy (coating, molding, printing) | Requires shaping/forming |

| Shielding (SE) | 40–70 dB | 60–90 dB |

| Frequency bandwidth | Broad | Narrower at GHz levels |

While metals still lead in maximum SE, CNT composites offer better design flexibility, durability, and integration potential for next-generation electronics.

Carbon nanotubes (CNTs) have transformed the landscape of EMI shielding materials.

Their combination of conductivity, absorption, lightweight structure, and mechanical robustness makes them ideal for modern electronic applications where metal solutions are too heavy or rigid.

Key takeaways:

-

CNT networks provide effective reflection and absorption of EM waves.

-

Proper dispersion and formulation are essential for consistent shielding performance.

-

CNT composites deliver stable, broadband EMI protection suitable for flexible, wearable, and high-frequency devices.

As global industries move toward miniaturized and mobile electronics, CNT-based EMI shielding will continue to expand — bridging the gap between lightweight design and high electromagnetic compatibility (EMC) performance.