CNTs in Aerospace Composites – Lightweight and Strong Materials

The aerospace industry has always pushed material science toward lighter, stronger, and more multifunctional structural solutions. Carbon fiber reinforced polymers (CFRPs) have dominated for decades, but as aircraft designs require even greater fuel efficiency, thermal stability, damage tolerance, and integrated sensing, engineers are now turning to carbon nanotubes (CNTs) as the next high-performance reinforcement.

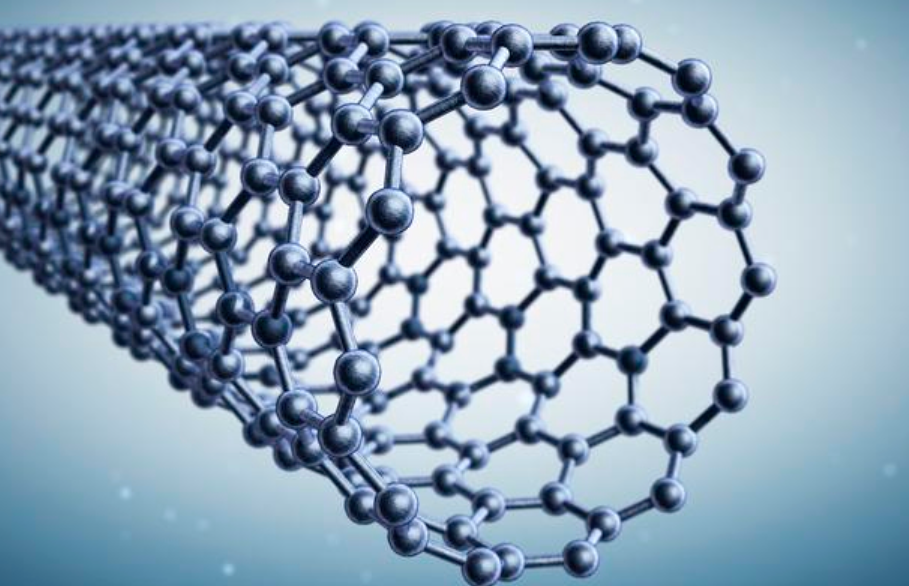

CNTs—whether multi-wall (MWCNT) or single-wall (SWCNT)—provide an unmatched combination of strength, stiffness, electrical conductivity, and thermal performance. When incorporated into aerospace composite matrices, they form a nanoscale reinforcing network that significantly improves mechanical, thermal, and functional properties without adding weight.

This article explains how CNTs boost aerospace composite performance, the mechanisms behind the improvements, processing challenges, and where CNT-reinforced materials are being deployed in aircraft, spacecraft, and UAV systems.

1. Why CNTs Are Ideal for Aerospace Structures

CNTs possess several key properties that align perfectly with aerospace material demands:

1.1 Ultra-High Strength and Stiffness

-

Tensile strength of CNTs can exceed 50–100 GPa

-

Young’s modulus is up to 1 TPa

This makes CNTs far stronger than carbon fibers on a per-weight basis.

1.2 Extremely Low Density

CNT density is around 1.3–1.4 g/cm³, much lower than aluminum and lighter than most fibers.

Meaning: significant reinforcement with almost no weight penalty.

1.3 High Electrical Conductivity

Provides:

-

Static dissipation

-

EMI shielding

-

Lightning strike protection

-

Structural health monitoring possibilities

without adding metal meshes or foils.

1.4 Superior Thermal Conductivity

CNTs conduct heat at:

-

Up to 3,000 W/m·K along the tube

-

Efficient pathways within the resin matrix

Useful for managing hotspots in satellites and aircraft electronics.

1.5 Crack Arresting and Toughening

CNTs act as:

-

Nano-bridges that prevent crack propagation

-

Energy absorbers that increase fracture toughness

Especially valuable in thin composite laminates vulnerable to delamination.

Together, these attributes make CNTs one of the most multifunctional reinforcements available for aerospace-grade composites.

2. How CNTs Improve Aerospace Composite Performance

CNTs improve composite matrices (epoxy, PEEK, PEKK, PPS, cyanate ester, etc.) through several mechanisms.

2.1 Improved Load Transfer

When CNTs are well-dispersed, their enormous surface area bonds with the polymer matrix, creating a continuous load-bearing network.

This leads to higher:

-

Tensile strength

-

Compression strength

-

Modulus

2.2 Enhanced Interlaminar Strength

Delamination is a common weakness in laminated aerospace structures.

CNTs:

-

Reinforce the interlaminar region

-

Improve fracture toughness

-

Prevent crack initiation under fatigue

In many studies and industrial trials:

-

Mode I fracture toughness increases by 40–80%

-

Interlaminar shear strength increases by 20–50%

These improvements dramatically increase composite reliability and lifespan.

2.3 Electrical Conductivity for Safety

Aircraft need lightning protection and static dissipation.

CNT networks create continuous conductive pathways, enabling:

-

Dissipating static buildup on composite surfaces

-

Reducing reliance on heavy copper mesh layers

-

Integrating structural health monitoring (SHM) systems

This reduces weight while maintaining safety.

2.4 Thermal Stability and Heat Dissipation

Aerospace thermal conditions can be extreme:

-

Re-entry heating

-

Cryogenic temperatures

-

Avionic hotspots

-

Engine-adjacent composite structures

CNT-enhanced composites:

-

Spread heat uniformly

-

Reduce hotspots

-

Improve thermal shock resistance

-

Maintain structural integrity across temperature cycles

2.5 Impact Resistance & Toughness

CNTs absorb energy during impact events such as:

-

Bird strikes

-

Runway debris

-

Tool drops during maintenance

The nanotubes deform and slide at the nanoscale, providing nano-damping that significantly enhances safety.

3. Manufacturing CNT-Reinforced Aerospace Composites

Aerospace engineers integrate CNTs through several industrial methods.

3.1 CNT-Modified Resin Systems

The most common approach:

CNTs are dispersed in epoxy, BMI, cyanate ester, or thermoplastic matrices, then used for:

-

Prepreg manufacturing

-

RTM (Resin Transfer Molding)

-

Filament winding

-

Pultrusion

Challenges:

-

Achieving stable dispersion

-

Controlling viscosity

-

Preventing CNT agglomeration

3.2 CNT-Grafted Carbon Fibers

Chemical grafting attaches CNTs directly to the fiber surface.

Benefits:

-

Improved fiber-matrix bonding

-

Enhanced interlaminar strength

-

Better impact resistance

This method is used in high-end aerospace components.

3.3 CNT Films and Veils

CNT nonwoven films are inserted between laminate layers.

They act as nano-reinforcement without disturbing resin flow.

Used for:

-

Interlaminar toughening

-

EMI shielding

-

Lightning protection layers

3.4 CNT Yarns and Tows

Emerging high-performance structural fibers made from aligned CNTs.

Advantages:

-

Very lightweight

-

Highly conductive

-

High tensile strength

Used selectively in space structures and advanced UAVs.

4. Key Aerospace Applications of CNT Composites

4.1 Aircraft Structural Components

CNTs reinforce or improve:

-

Wing skins

-

Fairings

-

Control surfaces

-

Nacelle structures

-

Door frames

-

Cabin structural panels

Improved fatigue resistance directly enhances airframe longevity.

4.2 Lightning Strike Protection (LSP)

Traditionally, metal meshes are added to CFRP surfaces.

CNT networks can replace them, offering:

-

70–90% weight reduction

-

Improved conduction

-

No corrosion

-

Simplified layups

This is one of the fast-growing industrial uses.

4.3 UAV and Drone Airframes

Benefits especially relevant to UAVs:

-

Lighter-than-carbon-fiber structures

-

Increased battery endurance

-

Greater flight time and payload capacity

CNT composites support both structure and electrical functions.

4.4 Satellite and Spacecraft Components

CNT-reinforced composite parts are used in:

-

Satellite panels

-

Structural brackets

-

Antenna booms

-

Thermal control structures

-

Radiation-resistant housings

CNTs tolerate vacuum, radiation, and extreme temperature cycles.

4.5 Engine and High-Temperature Components

With high-temp resins (PEKK, PEEK, BMI, cyanate ester), CNTs enhance:

-

Heat resistance

-

Crack resistance

-

Dimensional stability

Used in areas near engines or thermal exchangers.

4.6 Integrated Smart Structures

CNT networks enable:

-

Damage sensing

-

Stress monitoring

-

Predictive maintenance

-

Multi-functional skins

This aligns with the aviation industry’s shift toward intelligent airframes.

5. Engineering Considerations When Using CNTs

5.1 Dispersion Quality

Uniform dispersion = maximum strength.

Poor dispersion = agglomeration and weak spots.

5.2 CNT Loading Level

Typical loadings:

-

0.1–3 wt% for thermosets

-

1–5 wt% for thermoplastics

Higher loadings may increase viscosity.

5.3 Surface Functionalization

To improve bonding with aerospace resins, CNTs are often functionalized:

-

Carboxyl (–COOH)

-

Hydroxyl (–OH)

-

Amine (–NH₂)

-

Polymer grafting

This enhances compatibility and interfacial strength.

5.4 Processing Method Compatibility

Must evaluate CNT effect on:

-

Prepreg viscosity

-

Cure kinetics

-

Laminate porosity

-

Electrical network formation

Each aerospace application may require customized CNT types.

6. Future Outlook — The Rise of Nano-Engineered Airframes

CNT composites are enabling a new class of lightweight, multifunctional aerospace materials. Future developments will include:

-

CNT-only structural fibers replacing carbon fiber

-

Ultra-light conductive fuselage skins

-

Built-in lightning protection without metal meshes

-

Morphing wings with CNT heaters and actuators

-

Fully integrated sensing in aircraft composite structures

-

CNT-based thermal management for space systems

As manufacturing processes mature, CNT composites will play a central role in next-generation aircraft and spacecraft design.

Carbon nanotubes are dramatically transforming aerospace composites by enhancing mechanical strength, toughness, electrical conductivity, and thermal stability—all while reducing weight. Their ability to reinforce matrices at the nanoscale, improve interlaminar behavior, and add multifunctional capabilities makes CNTs one of the most impactful materials for high-performance aerospace engineering.

For UAV manufacturers, aircraft component suppliers, and aerospace composite developers, CNT-based solutions represent a strategic upgrade path for structures that must be lighter, stronger, and more reliable in harsh environments.