CNTs in Electric Aircraft Propulsion Systems: Enabling the Future of Sustainable Aviation

The aviation industry is undergoing a profound transformation. With the global push toward carbon neutrality and sustainable transport, the focus has shifted from fossil fuel–based propulsion toward electric and hybrid-electric aircraft. However, the shift to electric propulsion faces significant challenges, especially in power density, efficiency, thermal management, and weight reduction.

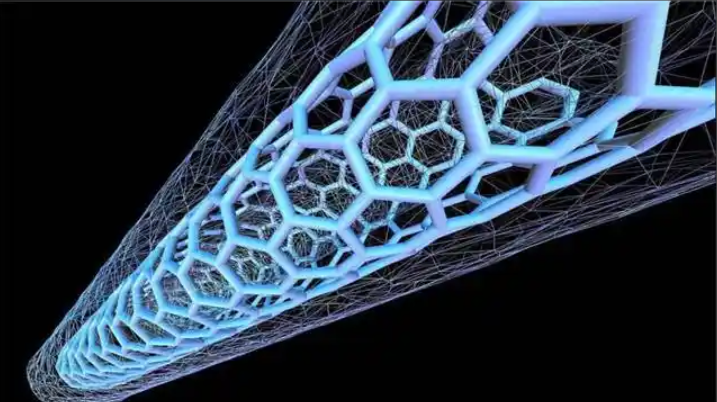

This is where carbon nanotubes (CNTs), one of the most versatile nanomaterials, offer transformative potential. CNTs are lightweight, mechanically robust, and highly conductive, making them an ideal enabler for next-generation electric aircraft propulsion systems. By enhancing motors, batteries, superconducting wires, and composite structures, CNTs can push the aviation sector closer to the goal of sustainable flight.

Why CNTs for Electric Aircraft?

Carbon nanotubes bring together multiple properties that are particularly beneficial for aviation propulsion:

-

Electrical Conductivity: CNTs can rival metals like copper but with significantly lower weight.

-

Mechanical Strength: Stronger than steel yet lightweight, reducing aircraft mass.

-

Thermal Conductivity: Helps manage heat in motors and batteries.

-

Flexibility and Processability: Can be integrated into composites, coatings, or even spun into fibers.

-

Electromagnetic Shielding: Protects sensitive avionics from interference.

These properties address some of the biggest bottlenecks in electric propulsion: heavy wiring, inefficient motors, overheating, and limited energy density in batteries.

Applications of CNTs in Electric Aircraft Propulsion

1. Lightweight Electrical Wiring

Traditional copper wiring is heavy, significantly affecting fuel and energy consumption. CNT-based conductors offer:

-

Weight reduction of up to 70% compared to copper.

-

Comparable or higher conductivity when bundled into fibers.

-

Improved fatigue resistance for long-term durability.

2. CNT-Enhanced Electric Motors

Electric aircraft motors require high efficiency and power density. CNTs contribute by:

-

Enhancing conductive windings for lighter and more efficient motors.

-

Providing thermal pathways to dissipate heat from coils.

-

Reducing electromagnetic losses through CNT composites.

3. CNT Composites in Propulsion Structures

CNT-reinforced polymers and composites can be applied in:

-

Motor housings that are lighter and more heat-resistant.

-

Propeller blades with higher durability and reduced weight.

-

Bearing and friction surfaces with improved wear resistance.

4. Energy Storage for Propulsion

One of the main barriers for electric flight is battery performance. CNTs improve:

-

Lithium-ion and solid-state batteries by increasing conductivity and energy density.

-

Supercapacitors for rapid power delivery during takeoff.

-

Thermal stability, reducing risks of overheating and fire.

5. Superconducting Systems

Research into CNT-based superconductors is ongoing, with potential for:

-

Ultra-efficient propulsion systems with near-zero resistance.

-

Power transmission lines in aircraft with minimal energy loss.

Case Studies and Research Highlights

-

NASA Research: Explored CNT-based wires to reduce the weight of onboard electrical systems.

-

MIT Studies: Developed CNT-based superconductors with potential for electric aircraft motors.

-

Airbus Initiatives: Investigated nanomaterials for lighter structural composites in hybrid-electric aircraft.

-

Japanese Researchers: Created CNT fibers with conductivity approaching copper, highlighting potential for aviation cabling.

These studies indicate that CNTs are moving from lab-scale innovations to real aerospace applications.

Benefits of CNTs in Electric Propulsion

-

Weight Reduction: Essential for improving flight range and efficiency.

-

Higher Efficiency: CNT conductors and composites minimize energy losses.

-

Thermal Management: Better heat dissipation ensures system stability.

-

Durability: CNT composites withstand fatigue, vibrations, and high stress.

-

Multifunctionality: Combines conductivity, strength, and shielding in one material.

Market Potential

The electric aircraft market is projected to exceed USD 30 billion by 2035, driven by regional air mobility, urban air taxis, and hybrid-electric planes.

Meanwhile, the carbon nanotube market is expected to reach USD 10+ billion by 2032, with aerospace among the fastest-growing segments.

This convergence creates a powerful growth opportunity for CNT-enabled propulsion technologies in aviation.

Challenges to Overcome

-

Production Costs: High-quality CNT fibers remain expensive to manufacture.

-

Scalability: Large-scale production of CNT-based conductors is still in development.

-

Integration: Ensuring CNT composites are compatible with aerospace certification standards.

-

Reliability: Long-term performance under high-stress aviation environments must be validated.

Addressing these challenges requires collaboration between nanomaterials researchers, aerospace engineers, and regulatory bodies.

Future Outlook

The role of CNTs in electric aircraft propulsion is expected to expand in the next decade:

-

Short-Range Urban Air Mobility: CNT wiring and composites could enable lighter, safer electric vertical takeoff and landing (eVTOL) aircraft.

-

Regional Commuter Planes: Improved batteries and propulsion motors with CNT integration.

-

Hybrid-Electric Aircraft: CNTs used in lightweight structures and power electronics.

-

Long-Term Vision: CNT-based superconductors enabling large-scale all-electric commercial aircraft.

With advancements in scalable CNT production, the aviation industry may see CNTs become a cornerstone material for sustainable electric flight.

The transition to electric aircraft propulsion systems requires breakthroughs in materials science, and carbon nanotubes provide a key enabler. Their combination of lightweight conductivity, mechanical strength, and multifunctionality makes them ideal for enhancing motors, wiring, batteries, and structural components.

From urban air taxis to regional commuter planes and future commercial aircraft, CNT-based materials promise to unlock the performance and efficiency needed to make sustainable electric aviation a reality.

As the aviation industry accelerates toward electrification, CNTs will play a central role in shaping the future of propulsion, delivering greener skies and innovative aircraft designs.