CNTs in Lithium-Ion Battery Electrodes – Conductive Additives and Networks

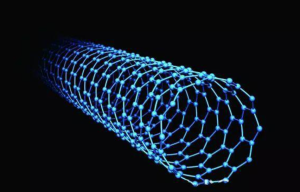

Lithium-ion batteries (LIBs) are the cornerstone of modern portable electronics, electric vehicles (EVs), and renewable energy storage. As the demand for higher energy density, faster charging, and longer lifespan grows, so does the need for advanced materials that can enhance the performance of LIBs. Carbon Nanotubes (CNTs), with their remarkable electrical conductivity, mechanical strength, and thermal properties, have emerged as a promising material for improving the electrode performance of lithium-ion batteries.

In this article, we explore how CNTs are used in lithium-ion battery electrodes, particularly as conductive additives and networks, and how they contribute to improving battery performance and efficiency.

1. The Role of Electrodes in Lithium-Ion Batteries

In a lithium-ion battery, the electrodes—comprising the anode and cathode—are crucial for the charge/discharge process. These electrodes are responsible for storing and releasing lithium ions during battery operation. The anode typically consists of graphite or silicon-based materials, while the cathode is commonly made from lithium metal oxide compounds.

The efficiency of these electrodes depends on several factors, including:

-

Conductivity: The electrode materials must efficiently conduct electrons and ions to enable fast charge/discharge cycles.

-

Mechanical Strength: The electrode materials should remain stable during cycling to avoid structural degradation.

-

Porosity: The electrodes must have the right level of porosity to allow for the movement of lithium ions.

This is where Carbon Nanotubes (CNTs) play a critical role. Their unique properties make them ideal candidates for improving electrode performance in lithium-ion batteries.

2. Why CNTs Are Ideal for Lithium-Ion Battery Electrodes

2.1 Exceptional Electrical Conductivity

Carbon Nanotubes (CNTs) exhibit extraordinary electrical conductivity, surpassing traditional conductive additives like carbon black or graphite. This makes CNTs an ideal material for enhancing the conductivity of battery electrodes, especially in high-performance batteries where fast charge/discharge rates are required.

By incorporating CNTs into the electrode structure, the battery can achieve more efficient electron transport, reducing internal resistance and improving overall performance.

2.2 High Surface Area

CNTs have an incredibly high surface area, which provides more active sites for lithium-ion storage and electron transfer. This can significantly increase the capacity of the electrodes, allowing batteries to store more energy while maintaining good power delivery.

2.3 Mechanical Strength and Flexibility

In addition to electrical conductivity, CNTs are known for their mechanical strength and flexibility. When integrated into battery electrodes, they can improve the structural integrity of the electrode material, reducing the risk of material cracking or degradation during the charging and discharging cycles. This enhances the cycle life of the battery, making it more durable and reliable over time.

2.4 Enhanced Thermal Conductivity

The high thermal conductivity of CNTs helps in dissipating heat generated during charging and discharging. This is important because excessive heat buildup can cause damage to the battery components, leading to capacity loss or even thermal runaway. By improving heat dissipation, CNTs contribute to the safety and longevity of lithium-ion batteries.

3. CNTs as Conductive Additives in Electrodes

One of the most common applications of CNTs in lithium-ion batteries is as a conductive additive in the electrode material. Traditionally, battery electrodes rely on conductive carbon additives to enhance the overall electron conductivity. However, these additives are typically not sufficient to maintain optimal performance, especially in high-performance applications.

3.1 Role of CNTs as Conductive Additives

By incorporating CNTs into the electrode material, manufacturers can:

-

Increase conductivity: CNTs improve the overall electron flow, reducing resistance and ensuring faster charge/discharge rates.

-

Prevent agglomeration: Unlike traditional carbon materials, CNTs form a network-like structure that prevents the particles from clumping together, ensuring a more uniform conductive pathway throughout the electrode.

-

Enhance cycle stability: CNTs provide mechanical reinforcement to the electrode structure, ensuring that it can withstand repeated expansion and contraction during cycling without degrading.

This use of CNTs as a conductive additive results in more efficient and reliable battery performance, especially for applications that require high power and long cycle life, such as electric vehicles (EVs) and power tools.

4. CNTs as Conductive Networks in Electrodes

In addition to being used as conductive additives, CNTs can be employed to form conductive networks within the electrode material. These networks act as electron highways, facilitating rapid electron transport across the electrode and significantly enhancing battery performance.

4.1 Creation of 3D Conductive Networks

By forming a three-dimensional network of CNTs, manufacturers can create a highly efficient electron transport system within the electrode. These networks help to:

-

Enhance power density: The network of CNTs facilitates faster electron movement, which allows the battery to deliver higher power during discharge.

-

Improve energy efficiency: A more efficient conductive network reduces energy losses, leading to higher energy efficiency during operation.

4.2 Flexibility and Durability

The flexible nature of CNTs also allows for the creation of flexible electrodes that can bend without losing conductivity. This is particularly useful for wearable devices, bendable electronics, and foldable displays. The durability of CNT networks also ensures that the electrode can handle multiple charge/discharge cycles without significant degradation, which improves the cycle life of the battery.

5. Applications of CNTs in Lithium-Ion Batteries

5.1 Electric Vehicles (EVs)

As the demand for electric vehicles grows, so does the need for more efficient and long-lasting lithium-ion batteries. CNTs enhance the performance of EV batteries by improving charging speed, power output, and cycle life. CNT-based electrodes are becoming increasingly important for achieving the high energy density and long lifespan required for EV applications.

5.2 Consumer Electronics

For smartphones, laptops, and other consumer electronics, batteries need to provide high power and long battery life without adding excessive weight or size. CNT-enhanced electrodes help achieve these goals by improving power density, charging time, and battery lifespan.

5.3 Energy Storage Systems

In renewable energy storage systems and grid storage, CNTs can improve the energy density and charging/discharging efficiency of large-scale lithium-ion batteries. These improvements help to make energy storage solutions more economical and sustainable.

6. Challenges and Future Outlook

While CNTs offer significant advantages for improving the performance of lithium-ion batteries, there are still some challenges to overcome:

6.1 Cost and Scalability

The cost of producing high-quality CNTs remains relatively high, which can make them expensive to incorporate into large-scale battery production. Cost-effective production methods need to be developed to make CNTs more affordable and scalable for commercial applications.

6.2 Dispersion and Integration

Achieving uniform dispersion of CNTs within the electrode material can be challenging. Poor dispersion can lead to inconsistent conductivity and poor battery performance. Researchers are working on methods to ensure uniform distribution and better integration of CNTs in battery electrodes.

6.3 Long-Term Stability

The long-term stability of CNT-enhanced electrodes must be thoroughly studied to ensure that the CNTs do not degrade over many charge/discharge cycles. This will be critical for ensuring the durability and reliability of CNT-based lithium-ion batteries.

Carbon Nanotubes (CNTs) are proving to be a transformative material for enhancing the performance of lithium-ion batteries, especially in terms of conductivity, mechanical strength, and thermal properties. By incorporating CNTs into the electrode material as conductive additives and networks, manufacturers can significantly improve the performance of batteries, resulting in faster charging, higher energy density, and longer lifespan.

As research continues and production techniques improve, CNTs are poised to play an increasingly important role in the development of next-generation batteries for electric vehicles, consumer electronics, and energy storage systems. The future of lithium-ion batteries lies in advanced materials like CNTs, which promise to deliver the power, efficiency, and durability needed for the evolving energy demands of tomorrow.