CNTs in Paints and Coatings – Conductive and Antistatic Finishes

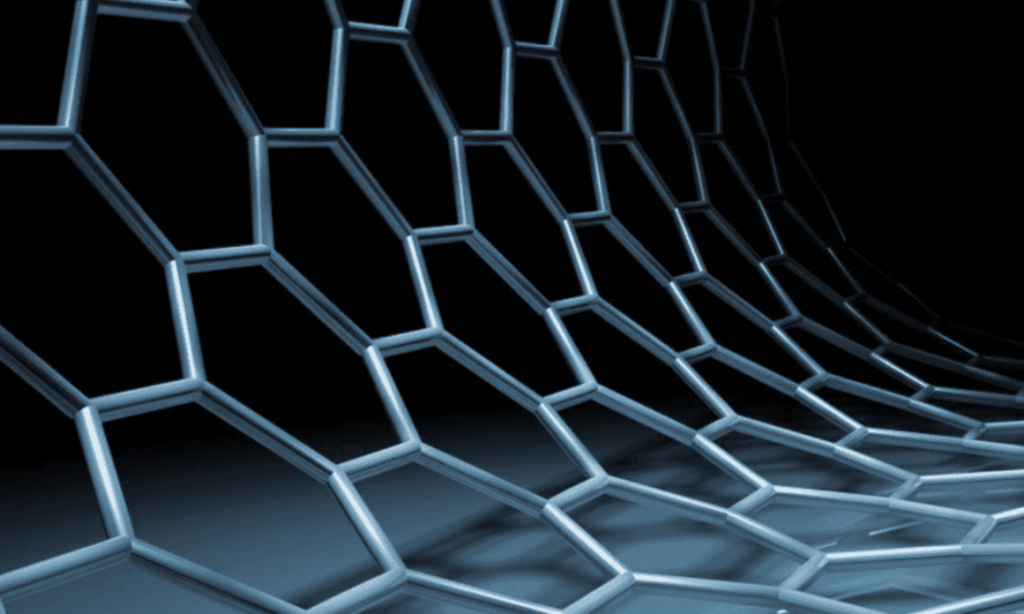

Carbon nanotubes (CNTs) have become one of the most effective additives for producing conductive, antistatic, and EMI-shielding coatings across industrial, electronics, automotive, and construction markets. Because CNTs form a lightweight, durable, and highly conductive network at very low loading levels, they provide outstanding performance without affecting coating appearance, viscosity, or mechanical properties.

This article explains how CNTs enhance coating functionality, the different CNT types used, formulation considerations, and how small and medium manufacturers can integrate CNT-based solutions into existing paint systems.

1. Why CNTs Are Used in Conductive and Antistatic Coatings

Traditional conductive fillers—such as carbon black, graphite, metal powders, or metal flakes—require high loading levels (10–30 wt%), which negatively impact:

-

Color and gloss

-

Viscosity and workability

-

Adhesion

-

Flexibility

-

Mechanical durability

CNTs solve this problem because of their high aspect ratio (>1000) and intrinsic conductivity.

Key Performance Advantages

✔ Conductive at extremely low loading (0.05%–1.0%)

✔ Stable, continuous conductive networks

✔ No visible particles – suitable for black, gray, or even transparent coatings

✔ High mechanical strength & abrasion resistance

✔ Chemical stability

✔ Lightweight and compatible with thin-film applications

CNT-enhanced coatings deliver conductivity without sacrificing appearance or physical properties.

2. What CNTs Do Inside a Coating

CNTs create percolation pathways—interconnected networks that allow electrons to move through the coating. This offers three major functional benefits:

2.1 Conductivity for ESD (Electrostatic Discharge) Control

CNT coatings can be engineered to achieve surface resistivity from:

-

10⁶–10⁹ Ω/sq → Antistatic

-

10³–10⁶ Ω/sq → Static-dissipative

-

10¹–10³ Ω/sq → Conductive

Used in electronics factories, cleanrooms, packaging, flooring, and equipment housings.

2.2 Antistatic Protection

Static charge causes:

-

Dust attraction

-

Safety hazards in chemical and solvent environments

-

Damage to electronic components

CNT-based antistatic coatings continuously bleed off charge, keeping surfaces stable and safe.

2.3 EMI Shielding Performance

CNTs reflect and absorb electromagnetic waves:

-

Improve shielding at 10 MHz–1 GHz

-

Enable thin, lightweight coatings compared to metal fillers

-

Support IoT devices, EV electronics, aerospace communication systems

CNTs are ideal for thin EMI-shielding coatings on plastics, films, or metal substrates.

3. Types of CNTs Used in Paints and Coatings

Different CNT forms offer different behavior in dispersions and final films.

3.1 Multi-Walled CNTs (MWCNTs)

Most widely used due to:

-

Robust structure

-

Lower cost

-

High conductivity

-

Compatibility with many resins

Ideal for industrial conductive paints and antistatic coatings.

3.2 Single-Walled CNTs (SWCNTs)

Advantages:

-

Higher conductivity

-

Lower percolation threshold

-

Better performance for transparent or thin coatings

Used for high-end electronics and premium EMI coatings.

3.3 Functionalized CNTs (–COOH / –OH / –NH₂)

Benefits:

-

Improved dispersion in waterborne or polar systems

-

Stronger bonding with polymer matrix

-

Better long-term stability

Common in water-based conductive coatings.

3.4 CNT Masterbatches / Dispersions

To help manufacturers avoid dispersion challenges, CNT suppliers often provide:

-

Water-based CNT dispersions

-

Solvent-based dispersions

-

Resin-compatible masterbatches (epoxy, polyurethane, acrylic)

These are easier to integrate and allow consistent QC during scale-up.

4. Resin Systems Compatible with CNTs

CNTs work well with most common coating systems:

✔ Epoxy

Used for flooring, anti-static equipment, tank linings.

✔ Polyurethane

Flexible coatings, industrial surfaces, automotive plastics.

✔ Acrylic

Conductive automotive clear coats, consumer electronics housings.

✔ Waterborne Latex

Environmentally friendly ESD paints for cleanrooms and factories.

✔ UV-Curable Resin

Electronics, 3D-printed parts, optical components.

CNTs do not significantly change curing behavior when properly dispersed.

5. Formulation Considerations

CNT coatings require careful engineering to ensure stable dispersion and predictable electrical performance.

5.1 Dispersion Quality Is Critical

Agglomerated CNTs reduce conductivity and cause film defects.

Optimizations:

-

Ultrasonic dispersion

-

High-shear mixing

-

Use of surfactants or dispersants

-

Pre-dispersed CNT inks (recommended)

5.2 Targeting the Percolation Threshold

Typically:

-

0.05%–0.2% for SWCNTs

-

0.1%–1.0% for MWCNTs

Below threshold → non-conductive

Above threshold → stable conductive network

5.3 Avoiding Viscosity Problems

CNTs can increase viscosity if added incorrectly.

Solutions:

-

Add CNTs slowly into resin

-

Use CNT-dispersions instead of raw powder

-

Choose functionalized CNTs for waterborne systems

5.4 Surface Smoothness and Color

CNTs do not affect gloss significantly at low loadings.

They are ideal for black, gray, silver, and metallic coatings.

For light-colored coatings, CNT loadings must remain very low or combined with other nano-fillers.

6. Applications of CNT-Based Conductive and Antistatic Coatings

CNT coatings are now widely used across multiple industries.

6.1 Electronics & Semiconductor Manufacturing

-

ESD-protective flooring

-

Worktables, assembly lines, tool housings

-

Racks, trays, and packaging

-

Equipment enclosures

Helps prevent damage to sensitive ICs and microchips.

6.2 Industrial & Chemical Plants

-

Solvent storage areas

-

Paint shops

-

Powder handling facilities

-

Fuel or gas environments

CNT coatings improve safety by preventing static buildup.

6.3 Automotive

-

Conductive plastic parts (interior panels, switches, sensors)

-

EMI shielding inside EV battery packs

-

Antistatic exterior coatings

CNTs support the high electronic density in modern EVs.

6.4 Aerospace

-

Lightweight EMI-shielding coatings

-

Antistatic coatings for composite panels

-

Conductive films for cockpit displays

CNTs outperform metal flakes by delivering higher shielding at lower weight.

6.5 Consumer Electronics

-

Smartphone housings

-

Laptop interiors

-

Wearable device casings

CNTs allow thin, lightweight coatings with good electrical performance.

6.6 Construction and Smart Buildings

-

Antistatic walls and floors

-

Conductive primers for grounded industrial areas

-

Heating coatings (CNT + graphene hybrids)

CNT-enhanced paints support smart building and automation systems.

7. Advantages for Small & Medium Manufacturers

CNT coatings allow companies to upgrade existing products without major equipment investments.

✔ Low dosage → stable cost structure

✔ Easy to integrate into current coating lines

✔ High durability → less maintenance for customers

✔ Eco-friendly options with water-based CNT dispersions

✔ Strong product differentiation (anti-static + conductive added)

Suppliers like Graphene Echo can provide:

-

CNT powder

-

CNT dispersions

-

Functionalized CNTs

-

Customized masterbatches

Helping customers reduce development effort.

8. Future Trends in CNT-Based Conductive Coatings

8.1 Transparent Conductive Coatings (CNT + Graphene)

Used for:

-

Display heaters

-

Smart windows

-

Antifogging lenses

Hybrid nano-films outperform ITO in flexibility.

8.2 CNT + Graphene for Heating Paints

By tuning resistance, coatings can provide:

-

Uniform heating

-

Defrosting

-

Floor heating

-

Battery preheating

8.3 Ultra-Thin EMI Shielding for EVs and 5G Electronics

CNT coatings will replace metal layers as electronics become lighter and thinner.

8.4 Water-Based, Eco-Friendly ESD Coatings

Growing global demand for safe, low-VOC solutions.

Carbon nanotubes provide one of the most effective strategies to create conductive, antistatic, and EMI-shielding coatings with minimal loading and maximum performance. Their combination of high aspect ratio, electrical conductivity, chemical stability, and compatibility with many resin systems makes them ideal for the next generation of industrial and electronic coatings.

For manufacturers, CNT-enhanced coatings offer:

-

Strong functional performance

-

Low material usage

-

Compatibility with existing paint-making processes

-

Clear differentiation in competitive markets

As industries continue moving toward lightweight electronics, electrification, and smart buildings, CNT-based coatings will play a central role in delivering conductive and antistatic performance efficiently and sustainably.