Graphene Aerogels in Hydrogen Storage Systems

Lightweight, High-Surface-Area Materials Powering the Hydrogen Energy Revolution

Hydrogen energy has become one of the cornerstones of the global clean energy transition. It offers a zero-emission alternative to fossil fuels, with water as the only by-product when used in fuel cells or combustion engines.

However, one of the biggest technical barriers to a hydrogen economy remains: safe, efficient, and lightweight hydrogen storage.

Traditional storage methods — such as high-pressure gas cylinders or cryogenic liquid tanks — are energy-intensive, costly, and often unsuitable for mobile or small-scale systems.

To overcome these challenges, researchers have turned their attention to advanced porous materials — and graphene aerogels have emerged as one of the most promising candidates.

Thanks to their ultralow density, high surface area, tunable pore structure, and excellent chemical stability, graphene aerogels can store large quantities of hydrogen through physisorption and chemical bonding mechanisms.

In short, graphene aerogels could provide a lightweight, solid-state route to compact hydrogen storage — enabling cleaner transportation and renewable energy systems.

1. What Are Graphene Aerogels?

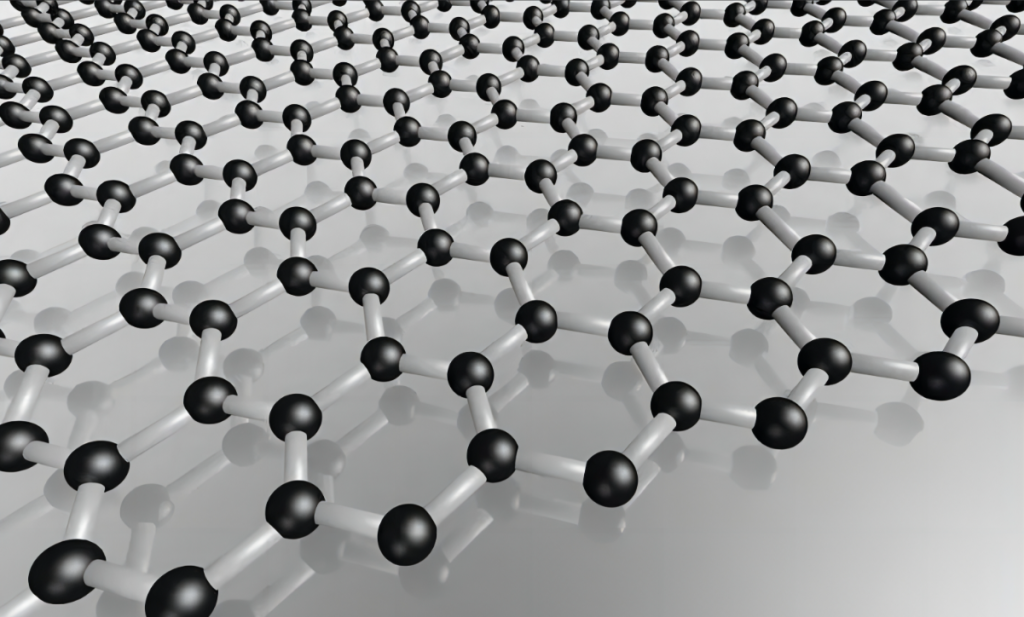

Graphene aerogels (GAs) are three-dimensional (3D) porous materials composed of interconnected graphene sheets.

They are typically produced by freeze-drying or supercritical drying of graphene oxide (GO) hydrogels, followed by thermal or chemical reduction to restore conductivity and mechanical strength.

Key Characteristics

| Property | Typical Value | Relevance |

|---|---|---|

| Density | 0.01–0.2 g/cm³ | Extremely lightweight |

| Surface Area | 500–1500 m²/g | High adsorption potential |

| Pore Size | 5–200 nm | Tunable for gas diffusion |

| Thermal Stability | Up to 500°C (inert) | Safe under operating conditions |

| Electrical Conductivity | 10²–10⁴ S/m | Useful for sensor or catalytic integration |

The hierarchical network of micro-, meso-, and macropores allows gases like hydrogen to diffuse easily and adsorb onto the internal surfaces — a critical feature for efficient hydrogen storage at ambient temperatures.

2. The Need for Advanced Hydrogen Storage Materials

Hydrogen’s low volumetric density means that 1 kg of hydrogen gas occupies about 11 m³ at standard conditions, making compact storage extremely challenging.

To meet the demands of fuel cell vehicles (FCVs) and portable energy systems, the U.S. Department of Energy (DOE) set targets for onboard hydrogen storage materials:

-

Gravimetric capacity: >5.5 wt% H₂

-

Volumetric capacity: >40 g/L

-

Operating temperature: <100°C

-

Cycling stability: >1500 cycles

Most conventional materials — like metal hydrides or carbon black — either fail to reach these targets or require extreme temperatures and pressures.

Graphene aerogels, with their extreme porosity and tunable surface chemistry, provide a pathway to store hydrogen efficiently under mild conditions, reducing both system weight and energy demand.

3. Hydrogen Storage Mechanisms in Graphene Aerogels

Graphene aerogels can store hydrogen through two primary mechanisms:

A. Physisorption

Hydrogen molecules physically adsorb onto the graphene surface via van der Waals forces.

This process is reversible and occurs rapidly, making it ideal for applications requiring frequent charge/discharge cycles.

Key factors influencing physisorption:

-

Surface area and pore size distribution

-

Surface functionalization (heteroatoms, defects)

-

Operating pressure and temperature

At cryogenic conditions (~77 K), graphene aerogels have shown hydrogen uptake up to 5–7 wt%, approaching DOE targets.

B. Chemisorption

In chemisorption, hydrogen atoms form covalent bonds with carbon atoms on the graphene framework (C–H bonds).

This results in higher binding energy but requires moderate heating (~200–300°C) for desorption.

By combining both mechanisms, graphene aerogels can achieve fast adsorption kinetics and stable hydrogen retention — crucial for mobile energy systems.

4. Surface Functionalization for Enhanced Hydrogen Uptake

Pristine graphene, while highly conductive and mechanically strong, has limited active sites for hydrogen adsorption.

To enhance performance, scientists modify graphene aerogels using chemical functionalization or metal doping.

A. Metal Nanoparticle Doping

Decorating graphene aerogels with metal nanoparticles (e.g., Pd, Pt, Ni, Mg) dramatically improves hydrogen storage by:

-

Catalyzing H₂ dissociation into atomic hydrogen;

-

Enhancing spillover effects, where hydrogen atoms migrate from metal sites to graphene surfaces;

-

Increasing binding energy between hydrogen and carbon.

For instance:

-

Ni–graphene aerogels have shown ~4.5 wt% H₂ storage at 77 K;

-

Pd–graphene aerogels reached ~5.8 wt% due to strong catalytic interactions.

B. Heteroatom Doping

Introducing nitrogen, boron, or sulfur atoms into the graphene lattice can:

-

Create defects and polar sites that attract hydrogen;

-

Tune the electronic structure for improved adsorption;

-

Maintain structural integrity over multiple cycles.

A study from the Chinese Academy of Sciences reported N-doped graphene aerogels with 6.1 wt% hydrogen uptake at 77 K and 1 MPa, outperforming undoped counterparts by 40%.

5. Advantages of Graphene Aerogels for Hydrogen Storage

Graphene aerogels combine several unique advantages over traditional materials:

| Feature | Benefit |

|---|---|

| High surface area | Enables dense hydrogen adsorption per gram |

| 3D porous network | Enhances diffusion and reversibility |

| Lightweight and robust | Ideal for mobile or aerospace systems |

| Tunable chemistry | Allows catalytic enhancement and defect control |

| Scalable synthesis | Compatible with printing or freeze-drying processes |

| Reversible adsorption | Fast charge/discharge with minimal degradation |

Because of these properties, graphene aerogels can bridge the gap between solid-state hydrogen storage and practical deployment in clean energy vehicles.

6. Integration with Hydrogen Energy Systems

A. Fuel Cell Vehicles (FCVs)

Hydrogen-powered vehicles demand compact, lightweight storage tanks. Graphene aerogels, when combined with metal hydrides or MOF structures, can increase total storage capacity while reducing system mass.

B. Portable Power Units

For drones, submarines, or off-grid electronics, aerogel-based hydrogen cartridges can store fuel at moderate pressures (~20–30 bar), improving both safety and energy density.

C. Renewable Hydrogen Infrastructure

Graphene aerogels can be integrated into hydrogen purification and compression systems, acting as both adsorbents and filters to maintain gas purity for fuel cells.

7. Experimental Results and Benchmarks

| Material Type | H₂ Storage (wt%) | Conditions | Reference |

|---|---|---|---|

| Pristine Graphene Aerogel | 1.8 | 298 K, 10 MPa | ACS Appl. Mater. Interfaces (2018) |

| Ni-Doped Graphene Aerogel | 4.5 | 77 K, 1 MPa | Int. J. Hydrogen Energy (2020) |

| Pd–Graphene Hybrid Aerogel | 5.8 | 77 K, 1 MPa | Carbon (2021) |

| N-Doped Graphene Aerogel | 6.1 | 77 K, 1 MPa | Energy Storage Mater. (2022) |

| rGO–CNT Aerogel Composite | 5.2 | 77 K, 1 MPa | J. Power Sources (2023) |

These data confirm that graphene-based aerogels are approaching the DOE 2025 hydrogen storage targets, particularly when combined with catalytic or heteroatomic modifications.

8. Challenges and Future Research

Despite their remarkable potential, several challenges must be overcome before graphene aerogels can be deployed commercially:

| Challenge | Description | Possible Solutions |

|---|---|---|

| Low hydrogen binding energy at ambient temperature | Requires cryogenic cooling for high uptake | Introduce catalytic metal sites or chemical doping |

| Structural collapse under cycling | Repeated adsorption/desorption may damage the pore network | Use crosslinked or polymer-reinforced aerogels |

| Scalability and cost | Complex synthesis limits mass production | Develop continuous freeze-drying or roll-to-roll fabrication |

| Safety and integration | Must meet industrial hydrogen safety standards | Combine with smart sensing and control layers |

Future directions include hybrid graphene–MOF composites, electrochemically controlled storage, and 3D-printed aerogel structures optimized for hydrogen mobility.

9. Sustainability and Environmental Impact

Graphene aerogels not only offer technical performance but also align with sustainability goals.

They can be synthesized from biomass-derived graphene oxide and processed using water-based green chemistry.

Furthermore, their ability to enable zero-emission hydrogen energy systems directly supports the global net-zero carbon targets for 2050.

From renewable hydrogen production to clean energy storage, graphene aerogels play a pivotal role in creating an environmentally responsible hydrogen economy.

10. Outlook: Toward a Hydrogen-Powered Future

The combination of graphene’s atomic thinness and aerogel’s 3D architecture represents a new paradigm for hydrogen storage materials.

With ongoing progress in doping, hybridization, and scalable synthesis, graphene aerogels are steadily moving from laboratory curiosity to industrial reality.

In the coming decade, these materials may form the core of:

-

Lightweight hydrogen tanks for electric aircraft and fuel cell vehicles;

-

Modular hydrogen cartridges for off-grid energy systems;

-

Hybrid storage–catalysis systems that generate, store, and release hydrogen on demand.

As the world accelerates toward hydrogen as a universal clean fuel, graphene aerogels could become the invisible infrastructure enabling a sustainable, low-carbon future.

Graphene aerogels are redefining hydrogen storage with their exceptional surface area, tunable porosity, and chemical versatility.

By integrating metal catalysts or dopants, they can achieve hydrogen capacities nearing theoretical limits under moderate conditions.

These lightweight, scalable materials have the potential to power next-generation fuel cells, electric vehicles, and clean energy grids, making them a cornerstone of the emerging hydrogen economy.

Graphene aerogel hydrogen storage represents not just a scientific achievement — but a tangible step toward realizing the dream of a truly sustainable, carbon-free energy world.