Graphene Aerogels in Oil Spill Clean-Up and Environmental Remediation

Oil spills are among the most devastating forms of environmental pollution. When crude oil or petroleum products leak into the ocean, they create long-lasting damage to marine ecosystems, coastal life, and local economies. Traditional cleanup techniques — such as chemical dispersants, skimmers, or synthetic absorbents — often fall short due to limited efficiency, poor selectivity, and secondary pollution.

Enter the era of Graphene Aerogels (GAs) — ultralight, porous, and super-absorbent materials that are redefining how we approach environmental cleanup. With extremely high surface area, strong hydrophobicity, and excellent recyclability, graphene aerogels offer a sustainable and highly effective solution for oil spill remediation and environmental protection.

What Are Graphene Aerogels?

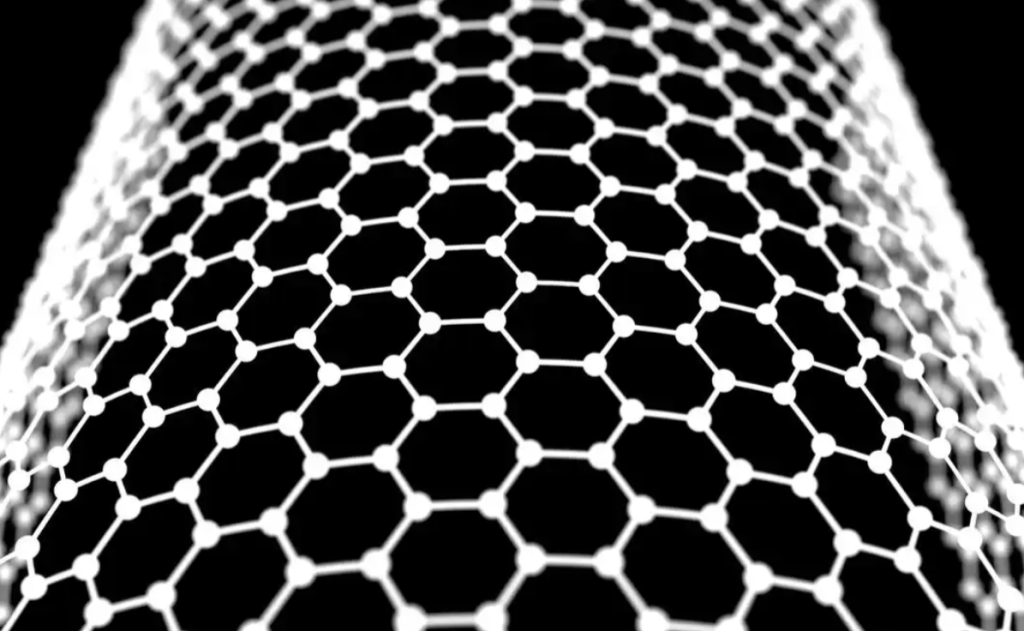

Graphene aerogels are three-dimensional porous networks made from interconnected graphene sheets. They combine the extraordinary properties of graphene — mechanical strength, high conductivity, chemical stability — with the structural advantages of an aerogel.

Typical characteristics include:

-

Density: as low as 0.01 g/cm³ (lighter than air in structure)

-

Surface area: > 500 m²/g

-

Porosity: > 99% open pore structure

-

Oil absorption capacity: up to 200–900 times their own weight

These features make graphene aerogels one of the most promising absorbents for removing oil and organic pollutants from water.

How Graphene Aerogels Remove Oil and Pollutants

The cleanup mechanism of graphene aerogels is primarily adsorption-driven, relying on their unique nanostructure and surface chemistry:

1. Superhydrophobic and Oleophilic Behavior

Graphene sheets naturally repel water (hydrophobic) while attracting hydrocarbons (oleophilic). When an oil spill occurs, the aerogel selectively absorbs oil while rejecting water, achieving high separation efficiency.

2. High Surface Area and Porous Structure

The enormous internal surface area and interconnected pores enable rapid oil diffusion and storage, allowing ultrafast absorption rates.

3. π–π Interactions and Van der Waals Forces

Oil molecules are trapped within the aerogel network through molecular interactions with graphene surfaces, ensuring stable adsorption.

4. Reusability and Regeneration

After saturation, the absorbed oil can be squeezed, heated, or burned off, restoring the aerogel for reuse — typically for dozens of cycles without significant loss of capacity.

Advantages of Graphene Aerogels in Oil Spill Clean-Up

1. Exceptional Absorption Capacity

Graphene aerogels can absorb hundreds of times their own weight in oil — outperforming traditional materials such as polypropylene pads or activated carbon.

2. Selective Absorption

Their hydrophobic–oleophilic nature ensures that only oil and organic compounds are captured, while water remains unaffected — critical for marine spill recovery.

3. High Recovery and Reusability

Graphene aerogels can be regenerated by simple thermal treatment or mechanical compression, maintaining over 90% efficiency after multiple uses.

4. Eco-Friendly and Non-Toxic

Made from carbon-based materials, graphene aerogels are environmentally safe, avoiding the secondary pollution associated with synthetic absorbents.

5. Scalability and Customization

By adjusting pore size, density, or surface functionalization, researchers can design aerogels tailored for specific contaminants — from crude oil to organic solvents.

Applications in Environmental Remediation

1. Marine Oil Spill Recovery

Graphene aerogel sponges can be deployed on ocean surfaces to rapidly absorb floating oil slicks. Their light weight allows them to float while maintaining high absorption efficiency, even in turbulent conditions.

2. Industrial Wastewater Treatment

In refineries and petrochemical plants, graphene aerogels can remove oil residues, dyes, and organic contaminants from wastewater streams, improving water reuse and reducing pollution.

3. Soil Remediation

When mixed with contaminated soils, GAs can immobilize and remove organic pollutants, aiding the recovery of oil-contaminated industrial sites.

4. Air Filtration and VOC Capture

Due to their high porosity and adsorption capacity, graphene aerogels can capture volatile organic compounds (VOCs) and airborne hydrocarbons, helping reduce industrial emissions.

5. Hybrid Environmental Systems

When combined with photocatalysts (e.g., TiO₂ or ZnO), graphene aerogels can both absorb and degrade pollutants, providing multifunctional environmental protection solutions.

Case Studies and Research Advances

-

Chinese Academy of Sciences (CAS): Developed a graphene aerogel sponge capable of absorbing up to 900 times its own weight in oil, with high recovery rates after multiple cycles.

-

MIT (Massachusetts Institute of Technology): Engineered a 3D reduced graphene oxide aerogel that efficiently separates oil-water mixtures and can be reused more than 10 times without loss of capacity.

-

National University of Singapore (NUS): Created magnetic graphene aerogels, enabling remote control and recovery of oil-laden sponges via magnetic fields — reducing manual cleanup risks.

Comparison with Conventional Oil Spill Materials

| Property | Graphene Aerogel | Polypropylene Pad | Activated Carbon |

|---|---|---|---|

| Absorption Capacity | Up to 900× weight | 10–20× weight | 30–50× weight |

| Selectivity (Oil vs Water) | Excellent | Moderate | Poor |

| Reusability | High (10–50 cycles) | Low (single-use) | Low |

| Biodegradability | Yes | No | Yes |

| Cost | Higher (currently) | Low | Moderate |

While graphene aerogels are still more expensive to produce, their high efficiency, reusability, and low environmental impact make them more economical in long-term, large-scale applications.

Challenges and Future Directions

Despite remarkable progress, graphene aerogels face several challenges before full industrial adoption:

-

Production Cost and Scalability — Mass-producing high-quality, uniform aerogels remains costly; scalable freeze-drying or 3D printing methods are under development.

-

Mechanical Fragility — While lightweight, graphene aerogels can be brittle; hybrid reinforcement with polymers or CNTs can enhance robustness.

-

Recovery Logistics — Large-scale deployment in open oceans requires systems for collection, regeneration, and safe handling.

-

Standardization — Environmental agencies must establish testing standards and safety regulations before commercial deployment.

Future innovations are focusing on:

-

3D-printable graphene aerogel composites for customized cleanup tools.

-

Magnetic or photocatalytic functionalization for dual-action cleanup.

-

Integration into autonomous cleanup drones or floating robots for real-time environmental protection.

Sustainability Impact

Graphene aerogels perfectly align with global sustainability goals by enabling:

-

Reduced chemical dispersant use in marine cleanup.

-

Closed-loop recovery systems that minimize waste.

-

Recyclable, carbon-based materials with minimal environmental footprint.

-

Cross-sector integration in oil, chemical, and environmental industries.

By transforming how we address oil pollution, GAs embody a circular economy approach — capturing, reusing, and repurposing resources that would otherwise harm ecosystems.

Graphene aerogels represent one of the most exciting advances in environmental nanotechnology. Their ultra-lightweight, porous, and superhydrophobic structure allows them to absorb vast quantities of oil while being reusable and eco-friendly.

From oceanic oil spills to industrial wastewater treatment, graphene aerogels provide a powerful, sustainable, and scalable solution for tackling some of the world’s toughest environmental challenges.

As production technologies mature and costs fall, we can expect graphene aerogels to become a cornerstone material in environmental remediation, helping safeguard our oceans, coastlines, and ecosystems for generations to come.