Graphene-Based Lubricants for Industrial Machinery: A New Era of Efficiency and Durability

Industrial machinery is the backbone of modern manufacturing, energy production, and transportation. From heavy-duty mining equipment to high-precision aerospace components, these machines operate under extreme conditions—high loads, elevated temperatures, and continuous friction. Lubrication has always played a critical role in reducing wear, extending service life, and improving energy efficiency.

g

g

In recent years, graphene-based lubricants have emerged as a revolutionary solution. With its unique two-dimensional structure, exceptional mechanical strength, and remarkable tribological properties, graphene is rapidly transforming how industries approach lubrication. Unlike conventional oils and greases, graphene additives provide superior protection, reduce downtime, and deliver long-term cost savings.

This article explores how graphene-based lubricants are shaping the future of industrial machinery, their working principles, applications, and commercial potential.

Why Traditional Lubricants Fall Short

Conventional lubricants—whether mineral-based or synthetic—perform adequately under moderate conditions. However, industrial machinery often encounters situations where standard lubricants fail:

-

High Temperature Instability: Traditional oils degrade at extreme temperatures, losing viscosity and protection.

-

Wear and Tear: Continuous metal-to-metal contact in high-load environments accelerates wear, reducing machine lifespan.

-

Contamination Issues: Dust, water, or chemicals easily compromise lubricant performance.

-

Energy Loss: Friction not only damages components but also wastes energy, leading to higher operational costs.

These challenges demand advanced lubrication technologies that go beyond conventional formulations.

The Science Behind Graphene Lubricants

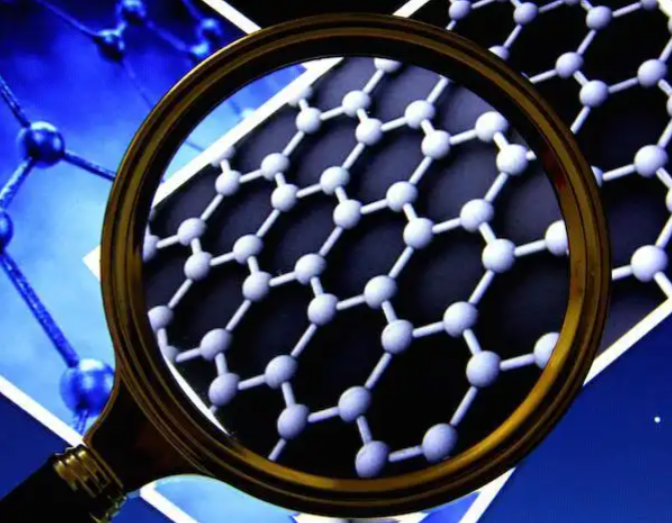

Graphene is a single layer of carbon atoms arranged in a hexagonal lattice. This nanomaterial is often called the “wonder material” due to its extraordinary properties:

-

High Mechanical Strength: ~200 times stronger than steel.

-

Ultra-Thin Layer: Only one atom thick, allowing it to form a protective coating at the microscopic level.

-

Low Friction Coefficient: Graphene reduces friction between moving parts dramatically.

-

Thermal Conductivity: Quickly dissipates heat, preventing thermal degradation.

When used in lubricants, graphene acts as both a protective film and a friction-reducing agent. It can be dispersed in oils, greases, or even dry powder formulations.

Working Mechanism:

-

Graphene nanosheets adhere to the surface of machine components.

-

They create a thin, robust barrier that prevents direct metal-to-metal contact.

-

The ultra-smooth carbon surface minimizes friction, reducing heat generation.

-

Graphene’s thermal conductivity helps distribute heat evenly, preventing hotspots.

Key Benefits of Graphene-Based Lubricants

1. Superior Wear Resistance

Graphene’s ultra-strong carbon lattice provides a self-healing protective layer. This significantly reduces surface wear, extending the lifespan of industrial machinery.

2. Reduced Friction and Energy Savings

By lowering the coefficient of friction, graphene lubricants improve operational efficiency. Studies show energy savings of up to 15% in certain applications.

3. High-Temperature Stability

Unlike traditional oils that degrade above 200°C, graphene-based lubricants remain stable at much higher temperatures, making them ideal for heavy-duty industries.

4. Extended Maintenance Intervals

Longer-lasting lubrication means fewer maintenance shutdowns. For industries like mining or steel production, this translates into millions of dollars saved annually.

5. Environmental Advantages

Graphene is non-toxic and biodegradable when properly formulated. Using graphene lubricants reduces reliance on harmful additives such as sulfur, phosphorus, and heavy metals.

Industrial Applications

Heavy Machinery & Mining

Excavators, loaders, and drilling equipment operate under extreme pressures and dusty environments. Graphene lubricants reduce wear in gearboxes, bearings, and hydraulic systems, extending operational uptime.

Automotive & Transportation

Engines, transmissions, and electric vehicle drivetrains benefit from graphene-enhanced oils. Reduced friction leads to lower fuel consumption and extended component life.

Aerospace Industry

Aircraft turbines and landing gear require lubricants that withstand high temperature and pressure. Graphene’s thermal stability and anti-wear properties make it a natural fit.

Steel & Manufacturing Plants

Rolling mills, conveyor systems, and robotic arms rely on continuous lubrication. Graphene-based greases ensure smooth operation under high loads and repetitive motion.

Renewable Energy

Wind turbines and solar tracking systems face long operational hours in remote locations. Graphene lubricants improve reliability, reducing costly field maintenance.

Market Potential and Adoption

The global lubricant market is worth over $150 billion annually, with industrial applications taking a major share. Analysts predict that nanomaterial-based lubricants—especially graphene-enhanced ones—will capture a growing portion of this market in the next decade.

Key drivers include:

-

Increasing demand for energy efficiency.

-

Rising focus on sustainability and green lubricants.

-

Expanding use of heavy-duty machinery in developing economies.

-

Strong R&D investment from both startups and established lubricant manufacturers.

Companies like SKF, Shell, and specialty nanotech firms are already testing or commercializing graphene-based lubricants.

Challenges and Considerations

While graphene lubricants are promising, several challenges remain:

-

Cost of Production: High-quality graphene is still relatively expensive, although costs are decreasing.

-

Dispersion Issues: Achieving stable graphene suspension in oils or greases requires advanced formulation techniques.

-

Standardization: Industry-wide testing protocols and certification are still evolving.

-

Scalability: Mass adoption requires large-scale production and supply chain readiness.

Despite these hurdles, the long-term benefits outweigh the limitations, and progress is accelerating.

Future Outlook

The future of lubrication is undoubtedly moving toward smart, nanotechnology-based solutions. In the coming years, we can expect:

-

Hybrid Lubricants: Combining graphene with other nanoparticles (e.g., molybdenum disulfide) for synergistic effects.

-

Self-Monitoring Systems: Graphene additives that also act as sensors, providing real-time feedback on lubricant performance.

-

Broader Adoption in Electric Vehicles: As EVs require specialized lubricants, graphene formulations will play a central role.

-

Cost Reductions: As graphene production scales, prices will drop, making it viable for widespread industrial use.

Graphene-based lubricants represent a game-changing advancement in the world of industrial machinery. Their ability to reduce friction, extend equipment life, and improve energy efficiency positions them as a critical tool for industries seeking performance and sustainability.

As manufacturing, transportation, and energy sectors push for greater efficiency and lower costs, graphene-enhanced lubricants will move from research labs into mainstream adoption. For businesses that rely on heavy machinery, investing in this technology today could mean significant competitive advantages tomorrow.