Graphene-Enhanced 3D Printing: Advancing Functional Additive Manufacturing

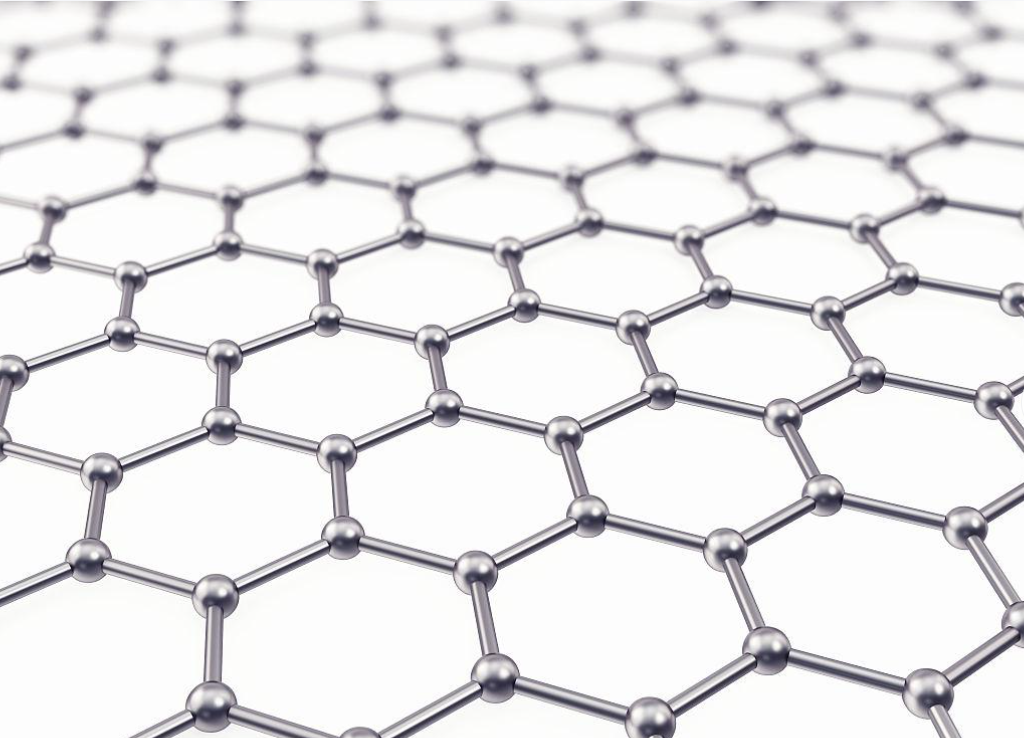

Additive manufacturing (AM), commonly known as 3D printing, has revolutionized prototyping and production in multiple sectors. However, traditional filaments and resins often lack the electrical, thermal, and mechanical performance required for advanced use cases. Enter graphene, whose extraordinary properties are transforming 3D printing materials from passive structures into functional, intelligent components.

🔹 1. Why Graphene for 3D Printing?

-

High thermal and electrical conductivity

-

Mechanical reinforcement

-

Biocompatibility for medical applications

-

Customizable dispersion in thermoplastics and resins

🔹 2. Key Applications

a. Conductive Components

-

Graphene-filled filaments (PLA, ABS, PETG) used to print circuits, antennas, sensors

-

Ideal for low-cost electronics and prototyping

b. Functional Prototypes

-

Automotive, aerospace prototypes with enhanced strength and EMI shielding

-

Graphene-polymer blends enable durable, functional models

c. Biomedical Devices

-

Biocompatible scaffolds for tissue engineering

-

Smart drug delivery capsules and implantable biosensors

d. Energy Storage

-

3D-printed batteries, supercapacitor housing, or electrodes

-

On-demand fabrication of customized power components

🔹 3. Commercial Developments

-

Graphene 3D Lab: Launched conductive graphene PLA filament

-

Nano Dimension: Printing circuits with graphene-based inks

-

Direct Ink Writing (DIW) with graphene composites under R&D for ultra-thin and stretchable devices

🔹 4. Technical Challenges

-

Ensuring homogeneous dispersion in polymer matrix

-

Balancing conductivity with mechanical flexibility

-

Printability issues with high filler content

Graphene is pushing 3D printing into the next dimension, enabling the creation of parts that are not only structural but also smart and functional. As printable formulations improve, we’ll see broader use of graphene-enhanced printing in electronics, healthcare, aerospace, and defense industries.