Graphene Heating Films – Technology Overview and Market Opportunities

Graphene heating films are ultra-thin, flexible heating elements that deliver rapid, uniform heating with low energy consumption. Because graphene conducts electrons and heat extremely efficiently, it enables thermal systems that are lighter, safer, and more intelligent than traditional resistive heaters.

This guide explains:

✅ Technology and materials

✅ Key performance advantages

✅ Form factors & customization

✅ Industry applications

✅ 2025–2030 market trends & business potential

What Are Graphene Heating Films?

A graphene heating film consists of:

| Layer | Function |

|---|---|

| Graphene conductive layer | Generates heat evenly |

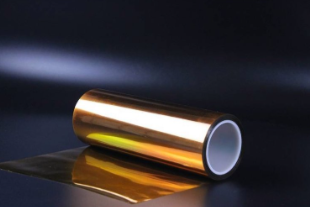

| Substrate (PET/PI, Cu foil, metal sheet) | Mechanical support |

| Electrodes & busbars | Uniform current distribution |

| Protective coating / insulation | Waterproofing, abrasion & corrosion protection |

Voltage can range from 3.7V → 380V AC, making graphene heaters suitable for both consumer electronics and industrial applications.

Graphene Heating Technology

Heat generation follows Joule heating:

P = I²R → fast heat with low resistance

Graphene’s sheet structure allows:

✅ Instant heat response (<1–3 seconds)

✅ Full-surface uniformity (no hotspots)

✅ High surface temperature (up to 150–300°C)

✅ Flexibility to fit curved surfaces

✅ Thin profiles: 20–80 μm

Graphene also supports integrated temperature control:

• NTC/PTC sensors

• Smart IoT heating modules

• Zonal heating patterns

Types of Graphene Heating Films

| Category | Substrate | Key Feature | Target Market |

|---|---|---|---|

| Copper-based Graphene Heaters | Cu foil | High power density | EV & battery systems |

| Iron/Aluminum-based Heaters | Metal foil | Anti-frosting, pipe protection | Industrial heating |

| PET / PI Flexible Films | Plastic polymer | Wearable & interior heating | Medical, automotive interior |

| Transparent Graphene Heaters | Glass or PET | Optical clarity | Displays, optical de-fogging |

We also supply etched graphene circuits for precision control.

Performance Comparison vs. Traditional Heating

| Metric | Nichrome Wire | Carbon Ink | Graphene Film | Best |

|---|---|---|---|---|

| Heating speed | Medium | Slow | ⚡ Fast | ✅ |

| Uniformity | Low | Medium | High | ✅ |

| Energy consumption | High | Medium | Low | ✅ |

| Flexibility | Poor | Good | Excellent | ✅ |

| Durability | Medium | Low | Excellent | ✅ |

Graphene films solve hotspot and fragility issues that plague wire heaters.

Applications

📌 Major industry demand drivers:

| Industry | Example Applications |

|---|---|

| EV & battery systems | Warming to boost winter performance |

| Consumer electronics | Phone backplate heaters, AR/VR |

| Smart wearables | Textile integration, medical therapy |

| Home appliances | Dryer, refrigerator de-frost |

| Buildings & infrastructure | Floor heating, glass de-fog |

| Industrial | Anti-condensation & logistics |

Any industry requiring thin, fast, energy-efficient heating is a target market.

Customization Capabilities

| Parameter | Typical Range |

|---|---|

| Power density | 0.3–2.5 W/cm² |

| Temperature | 20–300°C |

| Film thickness | 20–80 μm |

| Max width | up to 600 mm |

| Voltage options | 3.7V → 380V |

OEM/ODM available for full heating modules.

Certifications & Quality

-

RoHS / REACH / UL pending

-

10,000+ bending cycles

-

Waterproofing optional (IP65+)

Market Opportunities (2025–2030)

| Segment | Growth Driver | Estimated CAGR |

|---|---|---|

| Consumer electronics | Cheaper fast-charging devices | 18–22% |

| EV & battery | Cold-weather efficiency & safety | 25–30% |

| Building heating | Energy efficiency regulations | 20%+ |

| Wearable medical | Comfort & healthcare integration | 27% |

Graphene heaters represent the fastest-growing thermal market in the carbon industry.

Why now?

✅ COP28 regulations → efficiency focus

✅ New EV battery standards → thermal control required

✅ Smart surface heating becoming mainstream

→ Early adopters gain technology leadership and pricing power.

Graphene heating films provide a revolutionary alternative to bulky heating wires and inefficient carbon inks. With custom engineering support and scalable production, they are ready for widespread commercialization.

📩 Contact us for:

• Catalog & pricing

• Engineering design support

• Prototyping & mass production

→ Accelerate Your Thermal Innovation with Graphene Heating Filmshttps://graphenerich.com/about-us/contact-us/