Graphene in Food Packaging: Extending Shelf Life and Enabling Smart Monitoring

As global food supply chains become increasingly complex, the need for advanced food packaging that ensures freshness, safety, and transparency has never been greater. Traditional materials like plastic and aluminum fail to meet modern demands for real-time freshness monitoring, extended shelf life, and environmental sustainability.

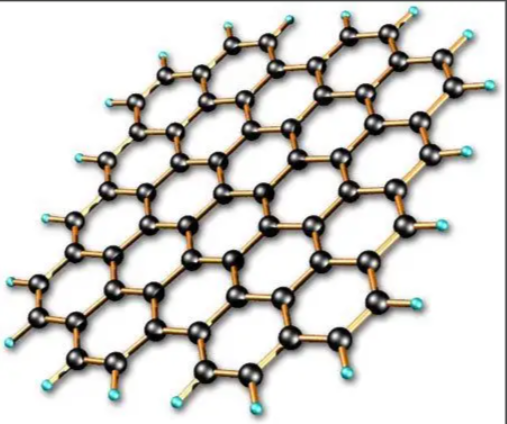

Graphene, with its unique properties, is transforming food packaging into a smart, active, and protective technology. From antimicrobial coatings to gas barrier layers and intelligent freshness indicators, graphene is enabling a new generation of high-performance food packaging materials.

🔹 1. Why Graphene is Suitable for Food Packaging

Graphene brings multiple advantages to packaging systems:

| Property | Impact on Packaging |

|---|---|

| High barrier property | Prevents oxygen, moisture infiltration |

| Antimicrobial effect | Inhibits bacteria, mold, and fungi |

| Mechanical strength | Enhances film durability and puncture resistance |

| Thermal stability | Withstands processing and storage temperatures |

| Sensing capability | Enables real-time monitoring |

These features are critical for perishable goods like meat, dairy, seafood, and fresh produce.

🔹 2. Graphene as a Barrier Film

Oxygen and moisture are primary culprits in food spoilage. Graphene, even as a monolayer, is impermeable to gases. When used as a coating or incorporated into plastic films:

-

Blocks oxygen, water vapor, and CO₂

-

Retains aromas and flavor profiles

-

Prevents oxidation of oils and vitamins

This results in extended shelf life without relying on heavy chemical preservatives.

🔹 3. Antimicrobial Packaging with Graphene Oxide

Graphene oxide (GO) has inherent antibacterial and antifungal properties due to:

-

Physical membrane disruption of microbes

-

Oxidative stress on bacterial cell walls

-

Ability to carry silver, copper, or essential oil agents

Studies show GO–polymer nanocomposites can reduce microbial load by over 90%, keeping food fresher for longer.

🔹 4. Graphene-Enabled Smart Packaging

With the rise of Internet of Things (IoT) in food logistics, packaging is becoming intelligent. Graphene enables:

-

Printed temperature/humidity sensors

-

Freshness indicators (pH, spoilage gases like NH₃)

-

RFID-based tracking

-

Colorimetric or electrochemical biosensors

For example, a graphene-based pH sensor embedded in meat packaging can change color or send a signal when spoilage begins.

🔹 5. Sustainable and Biodegradable Composites

Graphene can be combined with biopolymers like:

-

Polylactic acid (PLA)

-

Chitosan

-

Starch-based plastics

This creates eco-friendly films with enhanced barrier and mechanical properties, aligning with plastic reduction policies and green packaging initiatives.

🔹 6. Real-World Use Cases

| Product Type | Graphene Application |

|---|---|

| Packaged meats | Antimicrobial coating, freshness sensors |

| Dairy products | Barrier film to prevent light and oxygen damage |

| Fresh produce | Breathable nanocomposite wraps with GO |

| Frozen foods | Thermal stabilizing films |

🔹 7. Commercial Development and Challenges

-

Companies like NanoPack, Directa Plus, and Versarien are piloting graphene packaging systems

-

Regulatory approval is required for food-contact materials

-

Cost and scale-up of graphene composites remain challenges

-

Research is ongoing into edible graphene coatings for fruits and vegetables

Graphene’s multifunctional nature makes it a game-changer in food packaging. From increasing shelf life to enabling real-time freshness monitoring, graphene-infused films and coatings are moving from research labs to supermarket shelves. As cost and regulation hurdles are addressed, graphene-based food packaging will lead a smarter, safer, and more sustainable future for global food systems.