Graphene in Water Desalination and Filtration: Addressing Global Water Scarcity

Freshwater scarcity is one of the most pressing global challenges of the 21st century. According to the United Nations, more than two billion people live in countries experiencing high water stress, and by 2050, this number could increase dramatically due to climate change, population growth, and industrialization. Desalination and water purification technologies are vital for addressing this crisis, but conventional systems such as reverse osmosis (RO) membranes face limitations in energy efficiency, fouling resistance, and cost.

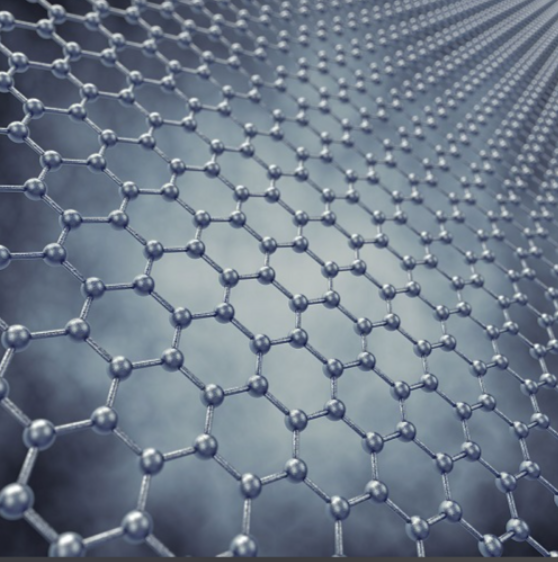

Graphene and its derivatives, particularly graphene oxide (GO), are emerging as game-changers in the field of water desalination and filtration. Their unique structural and physicochemical properties make them highly effective in separating salts, organic contaminants, and pathogens from water, paving the way for a sustainable water future.

Why Graphene for Water Filtration?

Graphene brings several advantages over traditional filtration materials:

-

Atomic Thinness and High Permeability – Graphene membranes allow water molecules to pass through rapidly while blocking salts and other solutes.

-

Precise Selectivity – Tunable nanochannels in graphene oxide membranes provide molecular-level separation.

-

Anti-Fouling Properties – Smooth and hydrophilic graphene surfaces resist biofouling and scaling, reducing maintenance needs.

-

Chemical and Mechanical Stability – Excellent resistance to harsh environments and long operational lifetimes.

-

Energy Efficiency – Reduced pressure requirements compared to conventional RO systems, lowering desalination costs.

Key Applications

1. Seawater Desalination

-

Graphene oxide membranes can effectively reject sodium and chloride ions while maintaining high water flux.

-

Compared with traditional RO membranes, graphene membranes offer higher efficiency at lower energy consumption.

-

Pilot projects have demonstrated that graphene-based desalination systems could produce potable water at lower operational costs.

2. Industrial Wastewater Treatment

-

Industries such as textiles, mining, and pharmaceuticals generate wastewater rich in dyes, heavy metals, and organic solvents.

-

Graphene membranes selectively remove heavy metals (e.g., lead, arsenic, chromium) and toxic organics, enabling safe water reuse.

-

Their robustness against chemical degradation makes them suitable for harsh industrial conditions.

3. Drinking Water Purification

-

Graphene composites can be integrated into portable water filters for household or emergency use.

-

Effective removal of bacteria, viruses, and organic pollutants ensures safe drinking water.

-

Potential applications in disaster relief, rural water supply, and military camps.

4. Membrane Distillation and Hybrid Systems

-

Graphene membranes can complement existing filtration methods such as RO or nanofiltration.

-

Hybrid graphene-polymer membranes improve selectivity and reduce fouling.

-

Potential to be integrated into solar-driven desalination systems for sustainable off-grid water production.

Advantages Over Conventional Membranes

| Feature | Traditional RO Membranes | Graphene-Based Membranes |

|---|---|---|

| Thickness | Tens of nanometers | Single-atom thick |

| Water Permeability | Moderate | Extremely high |

| Energy Requirement | High | Low |

| Salt Rejection Efficiency | High | High |

| Fouling Resistance | Limited | Strong |

| Longevity | Moderate | High |

Challenges and Limitations

Despite the promise, several hurdles remain before large-scale commercialization:

-

Scalable Production – Manufacturing defect-free graphene membranes at industrial scale is still under development.

-

Cost – Although graphene production costs are decreasing, they remain higher than conventional polymer membranes.

-

Durability – Long-term operational testing is needed to confirm performance in real-world environments.

-

Integration – Retrofitting existing desalination plants with graphene membranes requires further engineering work.

Future Outlook

The field of graphene-based water purification is progressing rapidly. Some promising future directions include:

-

Smart Membranes – Embedding sensors for real-time monitoring of water quality.

-

Hybrid Graphene Membranes – Combining graphene with carbon nanotubes or polymers for enhanced mechanical strength.

-

Energy-Efficient Systems – Pairing graphene membranes with renewable energy, such as solar desalination.

-

Commercial Expansion – Startups and research institutions are working on scaling up graphene membrane production for municipal and industrial deployment.

With ongoing advancements in nanomanufacturing, graphene could transform the water industry, making clean, affordable water accessible worldwide.

Graphene-based desalination and filtration technologies represent a major step forward in tackling global water scarcity. Their unique properties — high permeability, molecular selectivity, and durability — make them superior to conventional membranes in many respects. While challenges remain, continued progress in production and integration will bring us closer to a future where graphene membranes play a vital role in ensuring water security for millions of people.