Graphene Nanoplatelets in Concrete Reinforcement: Transforming the Future of Construction

Concrete is the most widely used construction material on Earth — forming the backbone of buildings, bridges, tunnels, and infrastructure. Yet despite its ubiquity, concrete suffers from well-known weaknesses: it is brittle, prone to cracking, and susceptible to environmental degradation.

For decades, engineers have searched for additives to make concrete stronger, more durable, and more sustainable. Now, a breakthrough nanomaterial — Graphene Nanoplatelets (GNPs) — is revolutionizing concrete technology.

By incorporating GNPs into cementitious composites, researchers and builders are achieving significant improvements in compressive strength, crack resistance, and longevity, paving the way for long-lasting and more resilient infrastructure.

What Are Graphene Nanoplatelets (GNPs)?

Graphene Nanoplatelets are stacks of a few layers of graphene sheets, typically 1–10 nanometers thick and less than 10 micrometers wide.

Unlike single-layer graphene, GNPs are easier and more cost-effective to produce in bulk, while still retaining many of graphene’s exceptional properties:

-

High tensile strength (up to 130 GPa)

-

Excellent thermal and electrical conductivity

-

Large surface area

-

Chemical stability and impermeability

These features make GNPs ideal for reinforcing composite materials, especially in cement and concrete systems.

How GNPs Reinforce Concrete

The improvement of concrete performance through GNPs arises from both physical and chemical mechanisms.

1. Microstructure Enhancement

GNPs act as nucleation sites during cement hydration, promoting the formation of a denser microstructure. This leads to:

-

Reduced pore size and porosity

-

Improved interfacial bonding between cement particles

-

Enhanced load distribution throughout the matrix

2. Crack Bridging and Toughening

GNPs can bridge microcracks and resist crack propagation. Their high aspect ratio allows them to absorb stress and prevent small cracks from growing into larger ones — improving tensile and flexural strength.

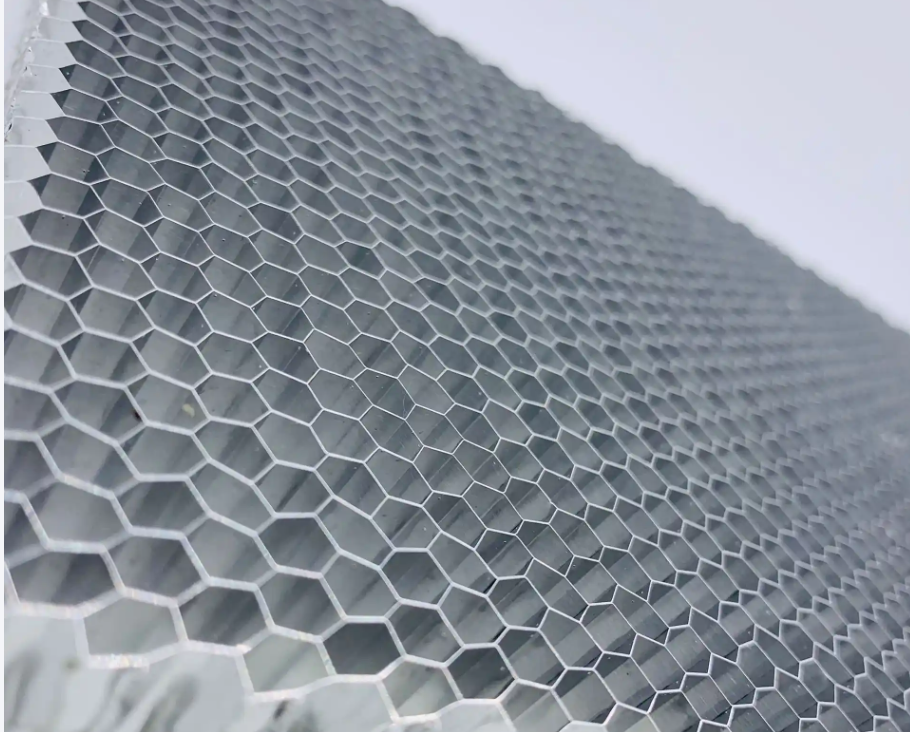

3. Barrier Protection

Due to their impermeability, GNPs reduce the penetration of water, chlorides, and other corrosive agents. This enhances durability and corrosion resistance in reinforced concrete structures.

4. Electrical and Thermal Functionality

The conductive nature of GNPs can turn traditional concrete into a smart material — capable of self-sensing, de-icing, or even energy storage.

Key Benefits of GNP-Enhanced Concrete

1. Higher Strength and Durability

Studies show that adding just 0.05–0.5 wt% of GNPs can increase compressive strength by 20–40% and flexural strength by 30–50%.

2. Improved Crack Resistance

GNPs effectively delay crack initiation and propagation, making concrete more resilient to dynamic loads and shrinkage.

3. Enhanced Durability Against Environmental Damage

GNP-reinforced concrete exhibits lower permeability, making it resistant to water ingress, freeze-thaw cycles, and chemical corrosion.

4. Self-Sensing and Smart Monitoring

The conductive network formed by GNPs enables concrete to detect strain or structural stress, opening pathways for smart infrastructure capable of self-diagnosis.

5. Sustainability

Stronger, longer-lasting concrete means less frequent repairs, lower maintenance costs, and reduced carbon footprint — aligning perfectly with global sustainability goals.

Applications of GNP-Reinforced Concrete

1. Buildings and Skyscrapers

GNP-enhanced concrete provides higher load-bearing capacity and crack resistance, improving the longevity and safety of high-rise structures.

2. Bridges and Overpasses

Bridges endure cyclic loading, temperature changes, and moisture exposure. GNPs improve fatigue life and corrosion resistance, extending service life.

3. Tunnels and Underground Structures

In tunnels exposed to humidity and pressure, GNPs enhance impermeability and prevent chemical degradation.

4. Marine and Coastal Infrastructure

Saltwater corrosion is a major challenge for marine concrete. GNPs act as a barrier layer, protecting rebar and reducing chloride ion penetration.

5. Smart Infrastructure

GNPs’ conductivity can transform concrete into self-monitoring structures that detect cracks, stress, or strain — ideal for future smart cities.

Case Studies and Research Insights

-

University of Exeter (UK): Researchers developed graphene-reinforced concrete that is twice as strong and four times more water-resistant than conventional concrete.

-

GrapheneCA and Italcementi: Developed commercial GNP-modified concrete mixes showing significant strength and durability improvements.

-

Chinese Academy of Sciences: Reported that GNPs improve ion diffusion resistance, enhancing long-term corrosion protection for steel-reinforced concrete.

Challenges and Optimization

Despite its promise, the widespread adoption of GNP-enhanced concrete faces several technical and economic challenges:

-

Dispersion — GNPs tend to agglomerate; uniform distribution is critical to achieve full reinforcement benefits.

-

Cost — Although cheaper than single-layer graphene, GNPs still increase material cost; optimization at low concentrations is essential.

-

Workability — GNPs can reduce fluidity of concrete mixes; admixtures are needed to maintain proper rheology.

-

Standardization — Lack of industry standards for graphene concrete testing and certification slows commercialization.

Future Prospects

The future of graphene nanoplatelet concrete looks promising as production becomes more affordable and consistent. Key directions include:

-

Hybrid Reinforcement Systems: Combining GNPs with carbon fibers, silica fume, or nano-silica for synergistic performance.

-

3D-Printed Concrete: Integrating GNPs into printable cement inks to create strong, lightweight, and durable printed structures.

-

Self-Healing Concrete: Using GNPs to enhance the performance of microcapsule- or bacteria-based healing systems.

-

Digital and Smart Infrastructure: Deploying GNP-enhanced concrete for structural health monitoring and adaptive control in future smart cities.

As these technologies mature, GNPs will play a central role in sustainable construction, reducing resource use and maintenance costs across global infrastructure.

Graphene Nanoplatelets (GNPs) are redefining how we think about concrete — transforming it from a traditional, brittle material into a high-performance, multifunctional composite.

By improving mechanical strength, crack resistance, impermeability, and durability, GNPs enable structures that last longer, perform better, and require less maintenance. From bridges and tunnels to skyscrapers and marine platforms, GNP-enhanced concrete represents the next step in advanced construction materials.

As scalability improves and costs decrease, graphene construction technology is poised to become mainstream — leading the world toward smarter, stronger, and more sustainable infrastructure.