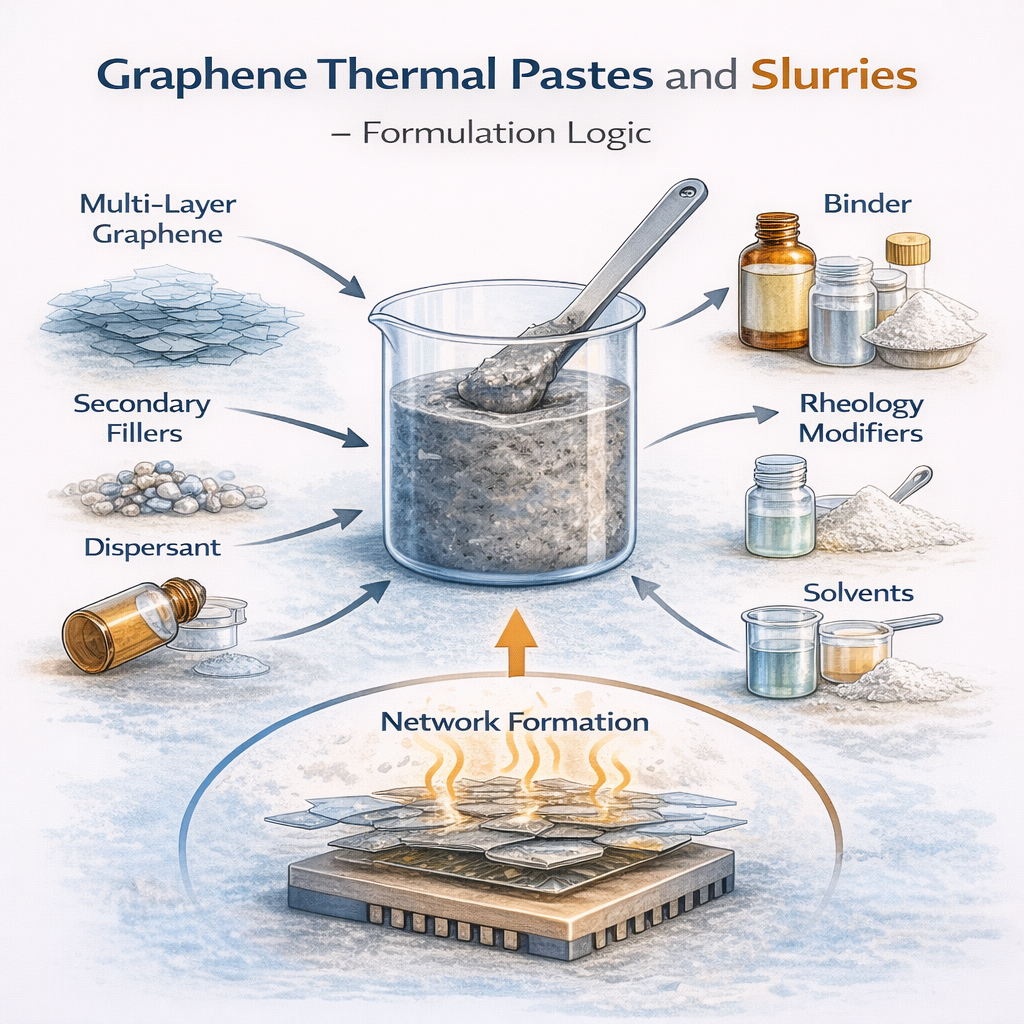

Graphene Thermal Pastes and Slurries – Formulation Logic

1. Why Graphene Thermal Formulations Matter

Graphene has extremely high intrinsic in-plane thermal conductivity, but in real applications—thermal pastes, coatings, and slurries—performance depends far more on formulation design than on raw material specifications.

A well-designed graphene thermal paste must balance:

-

Thermal conductivity

-

Processability

-

Stability

-

Interface contact

-

Cost

The challenge is not simply adding graphene—it is building an effective heat-transfer network within a workable formulation.

2. Thermal Pastes vs Slurries: Understanding the Difference

Although often grouped together, thermal pastes and thermal slurries serve different roles.

Thermal Pastes

-

High viscosity

-

Used as TIMs

-

Filled interfaces

-

Pressure-assisted contact

-

Controlled thickness

Thermal Slurries

-

Lower viscosity

-

Used for coatings or impregnation

-

Spray / brush / slot-die processes

-

Film-forming after drying or curing

Both rely on graphene networks, but their formulation priorities differ.

3. Core Components of Graphene Thermal Systems

A graphene thermal formulation typically includes:

-

Graphene or graphene-derived filler

-

Binder or matrix

-

Secondary fillers

-

Dispersants

-

Rheology modifiers

-

Solvent or carrier system

Each component influences thermal performance and stability.

4. Choosing the Right Graphene Type

Different graphene materials behave differently in formulations.

| Material | Typical Role |

|---|---|

| Multi-layer graphene | Main thermal network |

| Few-layer graphene | High conductivity boost |

| Graphene oxide (GO) | Dispersion aid |

| Reduced GO (rGO) | Thermal conductivity balance |

| Graphene nanoplatelets | Cost-effective spreading |

Multi-layer graphene is most commonly used in industrial thermal pastes due to:

-

Processability

-

Stability

-

Cost-performance balance

5. Network Formation: The True Performance Driver

Thermal conductivity increases when graphene forms:

-

Overlapping sheets

-

Continuous pathways

-

Low-resistance junctions

Key formulation goal:

Maximize network continuity at the lowest possible loading

Too little graphene → isolated flakes

Too much graphene → viscosity spike and agglomeration

Most systems reach optimal efficiency in the 5–20 wt% graphene range, depending on application.

6. Hybrid Filler Strategy

Pure graphene rarely delivers optimal performance alone.

Hybrid systems often include:

-

CNTs for bridging

-

Ceramic fillers for through-plane conduction

-

Metal particles for contact improvement

Benefits:

-

Lower graphene loading required

-

Better packing density

-

Reduced thermal contact resistance

Hybridization is often the most cost-effective route.

7. Dispersion Strategy

Dispersion determines:

-

Percolation threshold

-

Stability

-

Long-term performance

Key dispersion factors:

-

Mixing energy

-

Solvent compatibility

-

Surface functionalization

-

Addition sequence

Over-shearing can damage graphene sheets and reduce aspect ratio.

Under-shearing leaves agglomerates.

The goal is controlled exfoliation without structural damage.

8. Viscosity vs Thermal Conductivity Trade-Off

Increasing graphene loading improves conductivity but also increases viscosity.

Excess viscosity causes:

-

Poor coating

-

Trapped air

-

High contact resistance

-

Assembly difficulty

Engineering sweet spot:

-

Adequate network formation

-

Acceptable flow behavior

-

Stable film formation

This balance defines commercial success.

9. Interface Contact Is Often the Limiting Factor

In real assemblies, thermal resistance is dominated by:

-

Surface roughness

-

Micro-gaps

-

Air pockets

Graphene pastes must:

-

Conform to surfaces

-

Fill microvoids

-

Maintain stable contact over time

Soft matrices with well-dispersed graphene often outperform rigid high-loading systems.

10. Stability and Storage Considerations

Graphene slurries must remain stable during storage.

Common issues:

-

Sedimentation

-

Agglomeration

-

Viscosity drift

Stability strategies:

-

Density matching

-

Controlled particle size

-

Proper dispersants

-

Rheology tuning

Shelf stability is as important as thermal performance.

11. Processing Method Influences Formulation

Different application methods require different rheology:

| Method | Key Requirement |

|---|---|

| Screen printing | Thixotropic |

| Spray coating | Low viscosity |

| Dispensing | Shear thinning |

| Slot-die coating | Stable flow |

Formulation must match the process.

12. Cost–Performance Optimization

Graphene is a premium filler.

Adding more does not always improve performance proportionally.

Cost-effective strategies:

-

Hybrid fillers

-

Network optimization

-

Dispersion improvement

-

Interface engineering

The best formulation is not the one with the highest graphene content, but the one with the highest thermal efficiency per unit cost.

13. Engineering Takeaways

-

Graphene performance depends on network design

-

Dispersion quality shifts percolation behavior

-

Hybrid fillers often outperform pure graphene

-

Interface resistance dominates real systems

-

Viscosity must be engineered alongside conductivity

Graphene thermal pastes and slurries are not defined by graphene alone—they are defined by formulation logic.

Effective thermal systems require:

-

Controlled dispersion

-

Optimized filler loading

-

Strong interface contact

-

Stable processing behavior

When these elements align, graphene-based formulations can deliver reliable, scalable thermal performance across electronics, energy systems, and industrial applications.