Graphene vs Carbon Nanotubes: Which Is Better for Your Application?

Introduction: Two Carbon Giants

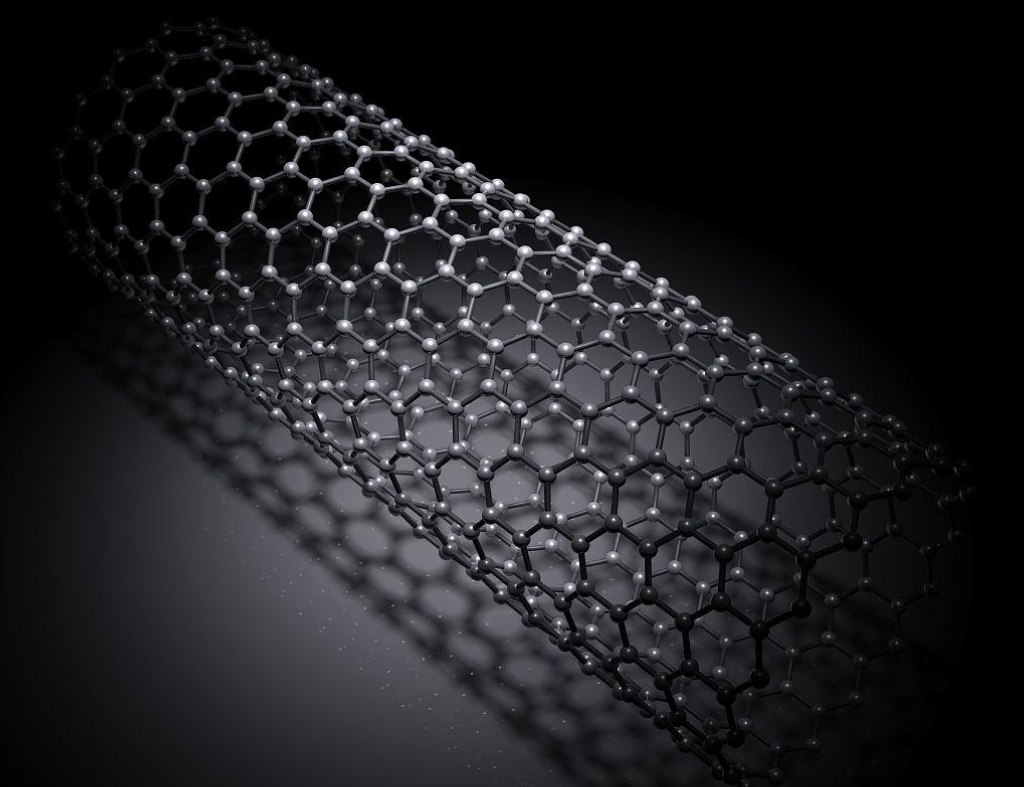

Graphene and carbon nanotubes are both made of carbon atoms, but their forms and functions differ. Understanding their strengths and trade-offs is key to choosing the right material for your project—whether it’s electronics, coatings, or composites.

Core Differences at a Glance

| Property | Graphene | Carbon Nanotubes |

|---|---|---|

| Structure | Flat 2D sheet | Cylindrical tube (1D/2D hybrid) |

| Surface Area | Extremely high | Moderate |

| Flexibility | Moderate | Excellent (especially SWCNTs) |

| Electrical Conductivity | Very high | High to ultra-high |

| Production Cost | Lower (now scalable) | Still high (for SWCNTs) |

| Ease of Integration | Easier to print and coat | Harder to disperse uniformly |

Application-Specific Comparison

-

Electronics & Conductive Films

-

Choose Graphene for transparent touch screens, EMI shielding

-

Choose CNTs for ultra-fast transistors, nanoscale wiring

-

-

Composite Materials

-

CNTs provide better tensile strength and flexibility

-

Graphene offers more surface adhesion and barrier properties

-

-

Thermal Management

-

Both excel; graphene for surface sheets, CNTs for vertical structures

-

-

Biosensing & Medical

-

CNTs are more sensitive for single-molecule detection

-

Graphene is better for imaging and broader sensor arrays

-

When to Combine Both

In advanced nanocomposites and flexible circuits, graphene and CNTs are often used together to create hybrid materials with synergistic benefits: strength, conductivity, flexibility, and durability all at once.

Conclusion

There’s no absolute winner between graphene and CNTs—it depends on your application. For large-area coatings and films, graphene shines. For mechanical reinforcement and precision nano-electronics, CNTs are ideal. In many cutting-edge projects, they work best together.