Graphene vs. CNT in Polymer Composites

How to Choose the Right Nanocarbon for Your Application

One Material Is Not Always Better

As nanocarbon materials become widely available, polymer engineers are increasingly faced with a practical question:

Should I use graphene or carbon nanotubes (CNTs)?

Both materials offer outstanding electrical, thermal, and mechanical properties—but they behave very differently inside polymer matrices. Choosing the right one depends less on “which is better” and more on what performance trade-offs matter most.

This article provides a practical selection framework for graphene vs. CNTs in polymer composites.

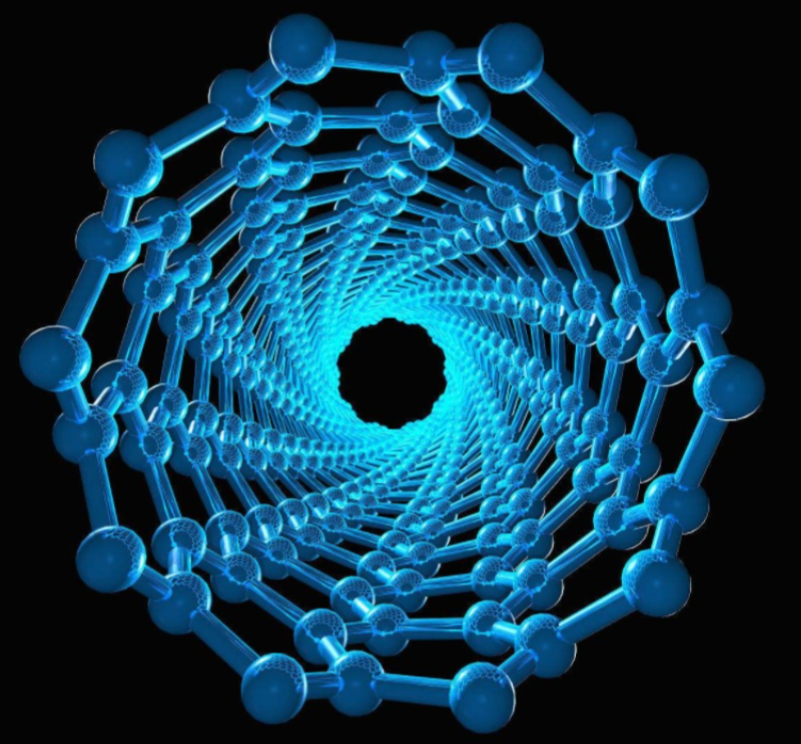

Structural Differences and Why They Matter

| Property | Graphene | CNT |

|---|---|---|

| Geometry | 2D sheets | 1D tubes |

| Aspect Ratio | High (lateral) | Extremely high |

| Network Formation | Overlapping layers | Entangled pathways |

| Primary Strength | Barrier & reinforcement | Conductive connectivity |

These structural differences directly affect percolation, dispersion, processing, and final performance.

Electrical Conductivity: Percolation Efficiency

CNTs excel in electrical conductivity.

-

CNTs form conductive networks at very low loading

-

Typical percolation: 0.1–1 wt%

-

Conductivity is stable under strain and vibration

Graphene typically requires higher loading to reach the same conductivity, especially in melt-processed polymers.

Selection rule:

➡ Choose CNTs when electrical conductivity is critical (ESD, EMI shielding, sensors).

Mechanical Reinforcement and Toughness

Graphene shines in mechanical enhancement.

-

Improves tensile strength and modulus

-

Enhances crack deflection and wear resistance

-

Acts as a two-dimensional reinforcement plate

CNTs can improve toughness, but mechanical gains are often secondary to conductivity.

Selection rule:

➡ Choose graphene for structural reinforcement and durability-focused composites.

Thermal Management and Barrier Properties

Graphene advantages:

-

Superior gas and moisture barrier performance

-

Effective heat spreading in-plane

-

Reduced permeability and aging effects

CNT advantages:

-

Better through-thickness thermal pathways at low loading

-

Useful in thermal–electrical hybrid functions

Selection rule:

➡ Graphene for barrier and heat-spreading

➡ CNTs for conductive thermal pathways

Processability and Dispersion

CNTs:

-

Sensitive to dispersion quality

-

Over-dispersion can damage tube structure

-

Masterbatch approach strongly recommended

Graphene:

-

Easier to disperse in many systems

-

GO compatible with waterborne and polar polymers

-

Less sensitive to shear damage

Selection rule:

➡ Graphene for coating, waterborne, and low-shear systems

➡ CNTs for controlled compounding and masterbatch routes

Cost and Formulation Efficiency

While graphene often costs less per kilogram, CNTs frequently cost less per functional unit due to low percolation thresholds.

| Metric | Graphene | CNT |

|---|---|---|

| Cost per kg | Lower | Higher |

| Typical Loading | 2–10 wt% | 0.1–1 wt% |

| Cost per Part | Medium | Often lower |

| Performance Density | Medium | High |

Selection rule:

➡ Evaluate cost per performance, not cost per kg.

Hybrid Graphene–CNT Systems: Best of Both Worlds

In many advanced composites, graphene and CNTs are used together.

Benefits of hybrid systems:

-

CNTs build conductive networks

-

Graphene reinforces structure and barrier properties

-

Lower total filler loading

-

Improved process stability

Hybrid systems are increasingly used in:

-

EMI shielding housings

-

Battery enclosures

-

Industrial coatings

-

High-performance thermoplastics

Application-Based Selection Guide

Choose Graphene when:

-

Mechanical reinforcement dominates

-

Barrier properties are critical

-

Coating or waterborne systems are used

-

Wear and corrosion resistance matter

Choose CNTs when:

-

Electrical conductivity is primary

-

Low percolation is required

-

Lightweight and thin-wall designs are needed

-

EMI or ESD performance is critical

Choose Hybrid Systems when:

-

Multiple performance targets must be balanced

-

Cost-performance optimization is needed

-

Long-term reliability matters

Testing and Validation Strategy

Regardless of material choice:

-

Always validate dispersion quality

-

Measure percolation behavior in real formulations

-

Test aging, thermal cycling, and mechanical fatigue

Material selection should be data-driven and application-specific.

Conclusion

Graphene and CNTs are not competitors—they are complementary tools in polymer composite design.

The right choice depends on:

-

Performance priorities

-

Processing route

-

Cost structure

-

Long-term reliability needs

By understanding how each material forms networks inside polymers, engineers can design smarter, lighter, and more reliable composites.