Graphene vs. Zinc-Rich Coatings

How to Choose the Right Corrosion Protection Strategy

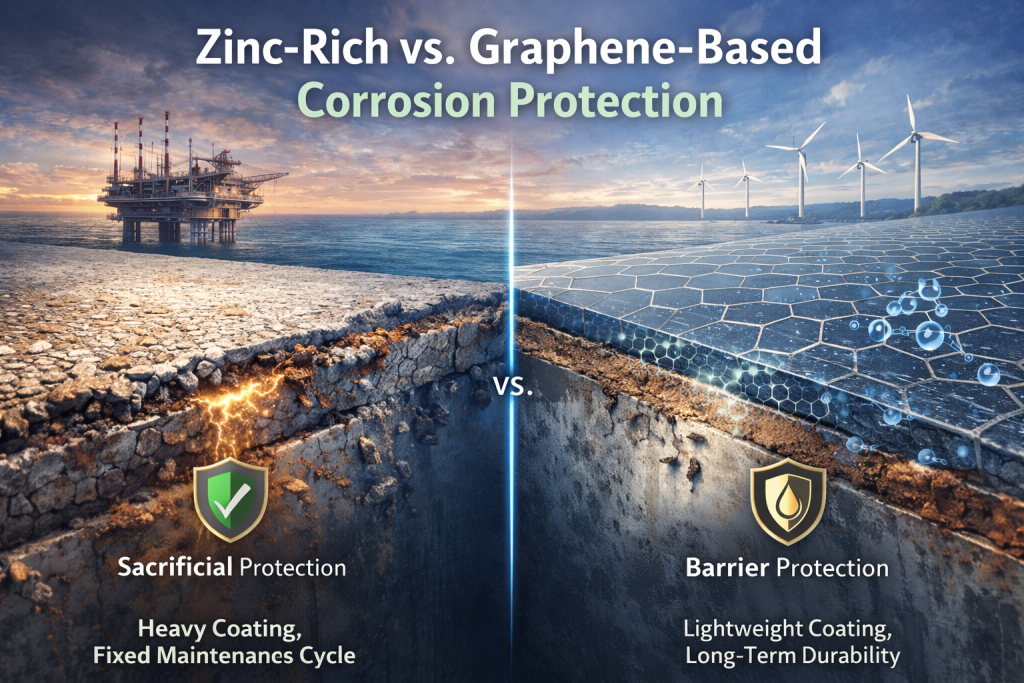

Not All Corrosion Protection Works the Same Way

Zinc-rich coatings have been the industry standard for steel corrosion protection for decades.

However, with increasing demands for longer service life, thinner coatings, and lower maintenance, alternative technologies such as graphene-enhanced coatings are gaining attention.

The key question is no longer “Which coating is stronger?”

but rather:

“Which corrosion protection mechanism fits my application best?”

How Zinc-Rich Coatings Protect Steel

Zinc-rich coatings rely on cathodic (sacrificial) protection.

Mechanism:

-

Zinc acts as a sacrificial anode

-

Zinc corrodes preferentially to steel

-

Steel remains protected as long as zinc is present

Typical characteristics:

-

Very high zinc loading (60–90 wt%)

-

Excellent short- to mid-term protection

-

Heavy coating weight

-

Limited flexibility

Zinc-rich coatings work extremely well—but only within their design assumptions.

How Graphene-Based Coatings Protect Steel

Graphene coatings rely on barrier-based corrosion protection.

Mechanism:

-

Graphene sheets form a tortuous diffusion path

-

Water, oxygen, and ions are blocked from reaching steel

-

Corrosion initiation is delayed rather than chemically consumed

This approach focuses on preventing corrosion from starting, rather than sacrificing material after it begins.

Key Differences in Protection Logic

| Aspect | Zinc-Rich Coatings | Graphene-Based Coatings |

|---|---|---|

| Protection Mechanism | Sacrificial (electrochemical) | Barrier (physical) |

| Typical Loading | Very high | Very low |

| Coating Thickness | Thick | Thin |

| Weight Impact | High | Minimal |

| Corrosion Strategy | Reactive | Preventive |

| Maintenance Cycle | Predictable consumption | Long-term stability |

Durability and Long-Term Performance

Zinc-rich systems:

-

Performance decreases as zinc is consumed

-

Protection eventually ends when zinc is depleted

-

Repair and recoating are expected

Graphene-based systems:

-

No sacrificial consumption

-

Protection depends on coating integrity

-

Performance remains stable if barrier remains intact

This makes graphene coatings attractive for long-life infrastructure where maintenance access is limited.

Mechanical and Application Considerations

Zinc-rich coatings often suffer from:

-

Brittleness

-

Poor flexibility

-

Cracking under vibration or thermal cycling

Graphene-enhanced coatings typically offer:

-

Improved adhesion

-

Crack resistance

-

Better performance under cyclic stress

This difference is critical in:

-

Wind towers

-

Offshore platforms

-

Renewable energy structures

-

Transport infrastructure

Environmental and Sustainability Factors

Zinc-rich coatings:

-

Require large amounts of metal

-

Increase material consumption

-

Produce corrosion by-products

Graphene coatings:

-

Use minimal additive loading

-

Enable thinner systems

-

Extend maintenance intervals

From a lifecycle perspective, graphene-based systems often deliver lower total environmental impact, even if initial material costs are higher.

Hybrid Systems: Zinc + Graphene

In practice, many advanced systems now combine both approaches.

Hybrid design logic:

-

Zinc provides sacrificial backup protection

-

Graphene improves barrier integrity

-

Total zinc loading can be reduced

-

Coating lifetime is extended

Hybrid zinc–graphene primers are increasingly used in marine and offshore environments.

Application-Based Selection Guide

Choose Zinc-Rich Coatings when:

-

Immediate cathodic protection is required

-

Standards explicitly require zinc systems

-

Maintenance access is available

-

Weight and thickness are less critical

Choose Graphene-Based Coatings when:

-

Long-term corrosion prevention is the priority

-

Thin and lightweight coatings are required

-

Structural durability matters

-

Maintenance intervals must be extended

Choose Hybrid Systems when:

-

Maximum protection is required

-

Both barrier and sacrificial mechanisms are desired

-

Total lifecycle cost optimization is important

Testing and Standards Considerations

Both systems are commonly evaluated using:

-

Salt spray testing

-

Cyclic corrosion tests

-

Adhesion and flexibility testing

Graphene-based systems increasingly demonstrate:

-

Comparable or superior salt spray performance

-

Better adhesion retention

-

Improved resistance to underfilm corrosion

Zinc-rich and graphene-based coatings are not direct replacements—they represent different corrosion protection philosophies.

-

Zinc-rich coatings protect by sacrificing material

-

Graphene coatings protect by blocking corrosion pathways

Understanding this difference allows engineers and asset owners to select the right system for the right environment, rather than relying on tradition alone.

As infrastructure lifetimes extend and maintenance costs rise, barrier-based graphene technologies are becoming a strategic complement—and sometimes an alternative—to zinc-rich systems.