High-Efficiency EMI Shielding Materials for In-Vehicle Electronics Using Carbon Nanotubes (CNTs)

As vehicles become increasingly digital, with advanced driver-assistance systems (ADAS), infotainment, and EV battery management systems, electromagnetic interference (EMI) poses a growing threat to performance and safety. Carbon nanotubes (CNTs) offer a next-generation solution for creating lightweight, flexible, and highly effective EMI shielding materials in automotive interiors.

1. The Challenge of EMI in Modern Vehicles

✔ Sources of EMI in Cars:

-

High-frequency switching in inverters and battery systems

-

Wireless connectivity (Bluetooth, Wi-Fi, GPS)

-

Infotainment displays and touchscreens

-

Onboard radar and sensor systems

✔ EMI Risks Include:

-

Malfunctioning electronics (GPS, sensors, infotainment)

-

Safety hazards in autonomous or ADAS systems

-

Signal corruption in data-heavy electric vehicles

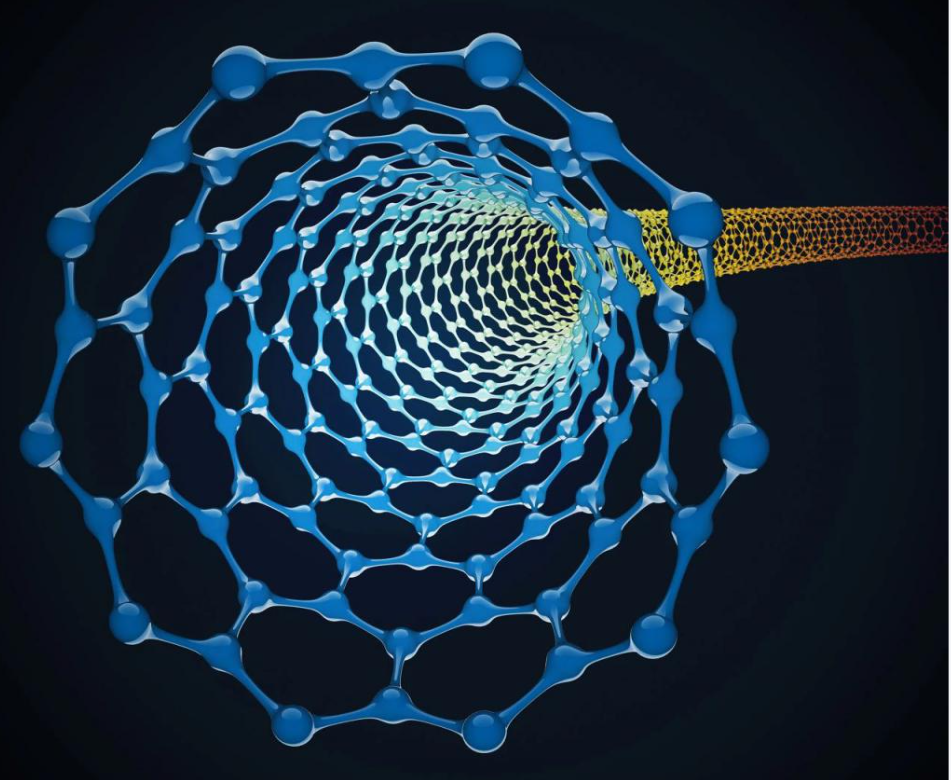

2. Why Carbon Nanotubes for EMI Shielding?

CNTs offer a unique combination of properties ideal for EMI protection:

| Property | Benefit |

|---|---|

| High electrical conductivity | Blocks and absorbs electromagnetic waves |

| High aspect ratio | Forms a continuous shielding network at low filler content |

| Lightweight | Reduces overall vehicle weight |

| Flexibility | Compatible with curved or complex interior surfaces |

| Thermal stability | Performs well in automotive temperature cycles |

3. Applications in In-Vehicle EMI Shielding

🔹 Instrument Panels & Infotainment Systems:

-

CNT-enhanced polymer composites used as shielding layers behind screens and controls

-

Maintains clear display functionality under EMI exposure

🔹 EV Battery Management Units (BMUs):

-

CNT films or coatings protect signal integrity and voltage monitoring

-

Enhances battery reliability and safety

🔹 Cable Shielding & Connectors:

-

CNT-coated braided sleeves or injection-molded parts for wiring harness EMI protection

-

Flexible and corrosion-resistant compared to traditional metal meshes

🔹 Sensor Housings & Radar Modules:

-

Embedded CNT shielding maintains sensitivity and accuracy of lidar/radar units

4. CNT EMI Shielding Mechanisms

✔ Reflection:

-

CNTs reflect incoming electromagnetic waves due to their conductive surface.

✔ Absorption:

-

The CNT network absorbs electromagnetic energy, converting it to heat.

✔ Multiple Internal Reflections:

-

The entangled CNT structure creates repeated scattering, weakening EMI intensity.

✔ Shielding Effectiveness (SE):

-

CNT-polymer composites can achieve >40–60 dB SE in the 1–10 GHz range, sufficient for automotive EMI standards.

5. Advantages Over Traditional Shielding Materials

| Material | Weight | Flexibility | Shielding Efficiency | Corrosion Resistance |

|---|---|---|---|---|

| Metal Foils (Cu, Al) | Heavy | Low | High | Moderate |

| Carbon Black | Light | Good | Low | High |

| Carbon Nanotubes | Ultra-light | Excellent | High | Excellent |

CNTs combine high performance with design freedom, allowing for 3D-printed parts, spray coatings, or extruded films.

6. Sustainable and Scalable Solutions

-

Lower filler loading (1–5%) means less material, reducing cost and environmental impact.

-

Hybrid composites using CNTs with graphene or silver flakes can further enhance performance.

-

Compatible with automated production (e.g., injection molding, roll-to-roll coating).

7. Outlook: Smart and Connected Vehicles

CNT-based EMI shielding enables:

✔ Reliable data transmission in autonomous systems

✔ Safe operation of EV battery and power modules

✔ Seamless infotainment and communications

✔ Weight reduction goals in sustainable automotive design

🔧 Conclusion

Carbon nanotube-enhanced EMI shielding materials are reshaping the way we protect in-vehicle electronics. Their lightweight, high-performance, and flexible nature makes them ideal for future smart, electric, and autonomous vehicles.

CNTs are not just shielding materials—they are enablers of safe, connected mobility. 🚗📶