Hybrid Graphene–CNT Networks – Balanced Strength and Conductivity

1. Why Hybrid Networks Matter

In advanced conductive and functional materials, a recurring challenge exists:

materials with high electrical conductivity often lack mechanical robustness, while mechanically strong materials may not deliver stable conductivity.

Graphene and carbon nanotubes (CNTs) individually address parts of this problem—but hybrid graphene–CNT networks offer a system-level solution that balances:

-

Electrical conductivity

-

Mechanical reinforcement

-

Processing stability

-

Cost-performance efficiency

This article explores why hybrid networks work, how they are designed, and where they outperform single-filler systems.

2. Limitations of Single-Filler Systems

Graphene-Only Systems

Strengths:

-

Excellent in-plane electrical and thermal conductivity

-

High barrier and reinforcement effect

Limitations:

-

Tendency to restack or aggregate

-

Conductivity highly orientation-dependent

-

Less effective in forming 3D conductive networks at low loading

CNT-Only Systems

Strengths:

-

Excellent 1D conductive pathways

-

Low percolation threshold

-

Strong bridging between particles

Limitations:

-

Limited planar coverage

-

Higher cost at high loadings

-

Less effective barrier performance

Hybrid systems address these complementary weaknesses.

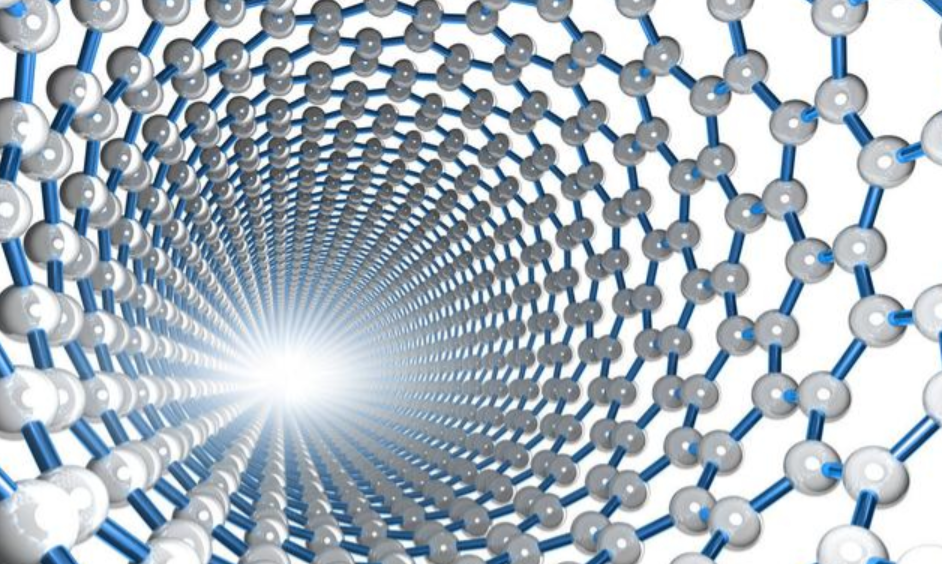

3. Architecture of Hybrid Graphene–CNT Networks

Hybrid networks combine 2D graphene sheets with 1D CNTs, creating a three-dimensional conductive and reinforcing structure.

Key structural roles:

-

Graphene sheets

-

Provide large-area conductive planes

-

Improve barrier and mechanical reinforcement

-

-

CNTs

-

Act as conductive bridges between graphene sheets

-

Prevent restacking and improve network continuity

-

This results in:

-

Lower percolation threshold

-

More isotropic conductivity

-

Improved mechanical integrity

4. Electrical Conductivity: Network Synergy

In hybrid systems:

-

Graphene provides high local conductivity

-

CNTs ensure long-range electron transport

Benefits:

-

Stable conductivity under strain

-

Reduced sensitivity to filler orientation

-

Improved conductivity at lower total filler loading

This makes hybrid networks ideal for:

-

Conductive coatings

-

EMI shielding materials

-

Flexible electronics

-

Antistatic and ESD plastics

5. Mechanical Reinforcement and Durability

Hybrid networks enhance mechanical performance through:

-

Crack deflection by graphene sheets

-

Stress transfer through CNT bridges

-

Improved filler–matrix interaction

Compared with single-filler systems:

-

Higher tensile and flexural strength

-

Better fatigue resistance

-

Improved resistance to micro-crack propagation

This is critical for cyclic loading, vibration, and thermal cycling environments.

6. Processing and Manufacturing Advantages

From an engineering perspective, hybrid systems offer better process tolerance:

-

Lower sensitivity to dispersion defects

-

Reduced viscosity increase at equivalent conductivity

-

Improved compatibility with polymers, coatings, and inks

This enables:

-

Easier scale-up

-

More stable batch-to-batch performance

-

Reduced scrap and rework rates

7. Cost–Performance Optimization

While hybrid systems may appear more complex, they often deliver better ROI:

-

Lower total filler loading

-

Reduced reliance on high-cost CNT grades

-

Improved durability reduces lifecycle costs

Key insight:

Hybrid design optimizes system cost, not just raw material price.

8. Application Areas Where Hybrid Networks Excel

| Application | Why Hybrid Works |

|---|---|

| Conductive Coatings | Balanced conductivity + mechanical stability |

| EMI Shielding | Isotropic conductive network |

| Flexible Electronics | Conductivity retention under strain |

| Anticorrosive Coatings | Barrier + conductive synergy |

| Energy Storage Components | Improved electron transport and structural stability |

9. Design Considerations for Hybrid Systems

To maximize performance:

-

Optimize graphene:CNT ratio

-

Ensure uniform dispersion of both fillers

-

Match surface chemistry to matrix system

-

Validate performance under real operating conditions

Hybrid networks are engineered systems, not simple material blends.

10. Future Outlook

Hybrid graphene–CNT networks represent a shift from single-material optimization to architecture-driven material design.

Trends include:

-

Application-specific hybrid formulations

-

Functionalized hybrids for enhanced compatibility

-

Integration into multi-functional coatings and composites

Hybrid graphene–CNT networks offer a balanced solution where conductivity, mechanical strength, and processing stability must coexist.

Rather than asking “Which material is better?”, the right question becomes:

“How should materials be architected to work together?”

For many advanced applications, hybrid networks provide the most practical and scalable answer.