Material Selection Logic Across Industries: Cost vs. Performance vs. Risk

1. The Complexity of Material Selection

Selecting materials for industrial applications is rarely straightforward. Beyond technical specifications, every decision involves balancing three core factors:

-

Cost – raw material, processing, and lifecycle expenses

-

Performance – electrical, thermal, mechanical, or chemical functionality

-

Risk – reliability, variability, compliance, and operational hazards

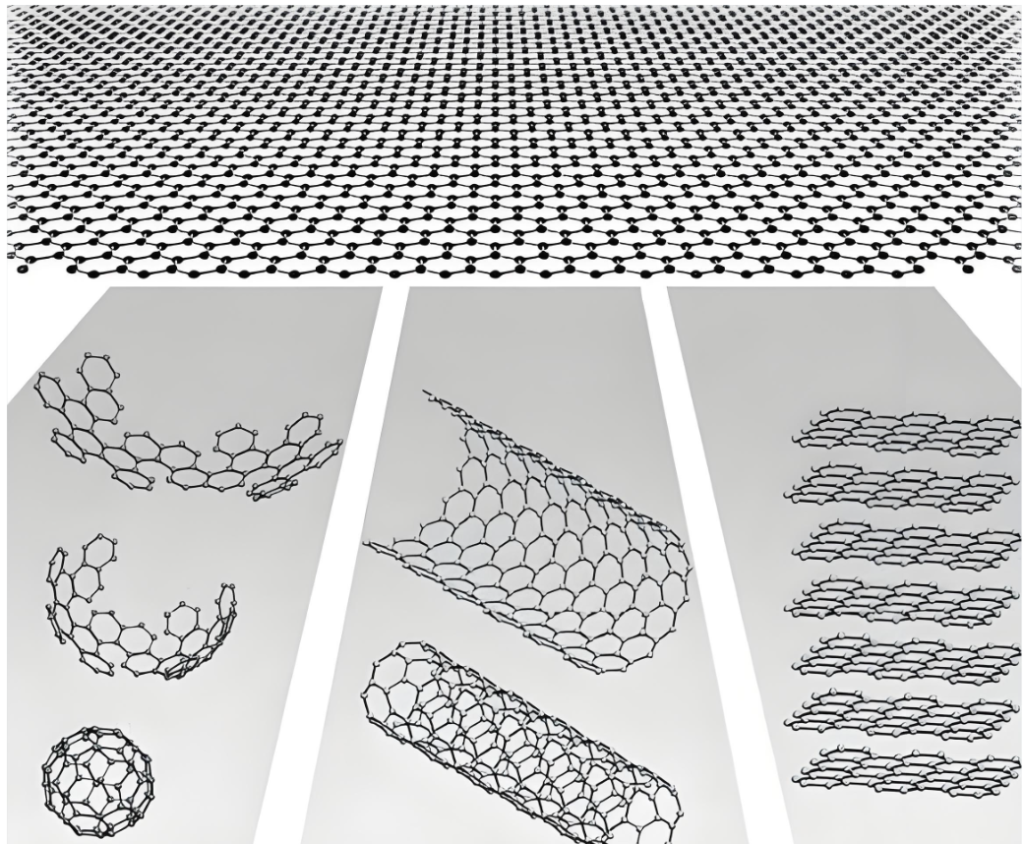

Advanced materials such as carbon nanotubes (CNTs), graphene, and hybrid systems highlight the importance of this logic. Choosing the wrong material can lead to over-engineered, costly, or unstable solutions, while the right choice can optimize total cost of ownership (TCO) and long-term ROI.

2. Understanding the Three Key Dimensions

2.1 Cost Considerations

Cost is often the first factor considered, but focusing solely on unit price can be misleading:

-

High-loading carbon black may appear cheaper per kilogram but can increase processing complexity and reduce mechanical performance.

-

CNTs, though more expensive upfront, often require lower loading, reduce scrap rates, and improve long-term reliability.

-

Graphene’s cost is justified when its planar conductivity or thermal performance delivers measurable functional advantages.

Key insight: True cost evaluation should include material, processing, yield, and maintenance.

2.2 Performance Requirements

Performance is multi-dimensional:

-

Electrical conductivity (bulk vs. surface vs. directional)

-

Thermal management and heat dissipation

-

Mechanical robustness under strain or fatigue

-

Environmental resistance (humidity, chemicals, UV)

Different industries prioritize different metrics:

| Industry | Primary Performance Focus |

|---|---|

| E-Mobility | Thermal management & conductivity under cycling |

| Smart Devices | Flexibility, thinness, and stable conductivity |

| Industrial Control | Long-term stability and environmental resistance |

2.3 Risk Evaluation

Risk encompasses both operational and business aspects:

-

Material variability: batch-to-batch differences can impact final product performance

-

Process compatibility: some fillers affect viscosity, curing, or molding

-

Environmental and regulatory risks: safety, toxicity, and sustainability compliance

-

Failure cost: industrial applications may tolerate little to no performance deviation

Effective selection reduces risk by aligning material characteristics with application constraints.

3. Decision Logic Framework

A simple framework can guide selection:

-

Define Application Requirements

-

Electrical, thermal, mechanical, environmental

-

-

Prioritize Factors

-

Rank Cost vs. Performance vs. Risk based on market and industry needs

-

-

Evaluate Material Options

-

CNT, graphene, carbon black, hybrid systems

-

-

Simulate or Prototype

-

Test minimal loading for required performance

-

Validate environmental and mechanical stability

-

-

Assess Total Cost of Ownership (TCO)

-

Material cost + processing + yield + maintenance + risk mitigation

-

4. Industry-Specific Insights

4.1 E-Mobility

-

Cost vs. Performance: Reliability dominates; higher material cost is justified

-

Preferred Materials: CNTs for conductive networks; hybrids for thermal enhancement

-

Risk Mitigation: Focus on lifetime performance under cycling and temperature extremes

4.2 Smart Devices

-

Cost vs. Performance: Low loading, high conductivity, flexibility

-

Preferred Materials: CNTs for conductivity; graphene for planar and thermal optimization

-

Risk Mitigation: Maintain uniformity in thin-film and printed electronics

4.3 Industrial Control

-

Cost vs. Performance: Balanced; long-term stability critical

-

Preferred Materials: CNT-based coatings and plastics; hybrids when additional thermal or planar conductivity needed

-

Risk Mitigation: Ensure process reproducibility, environmental resistance, and batch consistency

5. Material Trade-Off Examples

| Material | Cost | Performance | Risk | Optimal Use |

|---|---|---|---|---|

| CNT | Medium–High | High (network stability) | Low | ESD plastics, flexible electronics, battery additives |

| Graphene | Medium | High (planar/thermal) | Medium | Thermal coatings, barrier films, composites |

| Hybrid CNT–Graphene | Medium–High | Very High | Low | EMI coatings, multifunctional plastics, thermal-electrical composites |

| Carbon Black | Low | Moderate | Medium–High | Commodity plastics, low-reliability applications |

Key takeaway: Material choice depends less on absolute price and more on system-level impact on performance, reliability, and total cost.

6. Risk-Aware Design Principles

-

Prioritize functional requirements over raw material cost

-

Validate minimal effective loading to balance cost and performance

-

Assess processing and manufacturing impact early

-

Integrate lifecycle and environmental considerations

-

Consider hybrid or combination systems for multifunctional applications

This logic ensures decisions are defensible and aligned with both technical and business objectives.

7. Future Trends in Material Selection

-

Increasing use of hybrid systems for multi-dimensional performance

-

Growth in application-specific CNT and graphene grades

-

Greater emphasis on predictable performance and lifecycle ROI rather than raw conductivity

-

Adoption of decision frameworks and digital simulation in material selection

Cross-industry material selection is a complex balance of cost, performance, and risk. CNTs, graphene, and hybrid systems each offer unique advantages, but the right choice depends on:

-

Application requirements

-

Processing and manufacturing constraints

-

Lifecycle and total cost considerations

By applying a structured decision framework, manufacturers can optimize materials for performance, reliability, and ROI, reducing risk while enabling innovation across E-mobility, smart devices, industrial control, and beyond.