Reduced Graphene Oxide in Flexible Electronics: A New Era of Conductive Films

The era of flexible electronics is here. From bendable smartphones to wearable health monitors and curved displays, the demand for materials that combine conductivity, transparency, and mechanical flexibility has never been greater.

For decades, Indium Tin Oxide (ITO) has been the industry standard for transparent conductive films. However, ITO suffers from brittleness, scarcity, and high production costs, making it unsuitable for the next generation of flexible and stretchable devices.

This has driven researchers and manufacturers to explore alternatives, and one of the most promising candidates is Reduced Graphene Oxide (rGO). With its tunable conductivity, mechanical flexibility, and scalable production, rGO offers a sustainable and versatile solution for flexible electronic applications.

What is Reduced Graphene Oxide (rGO)?

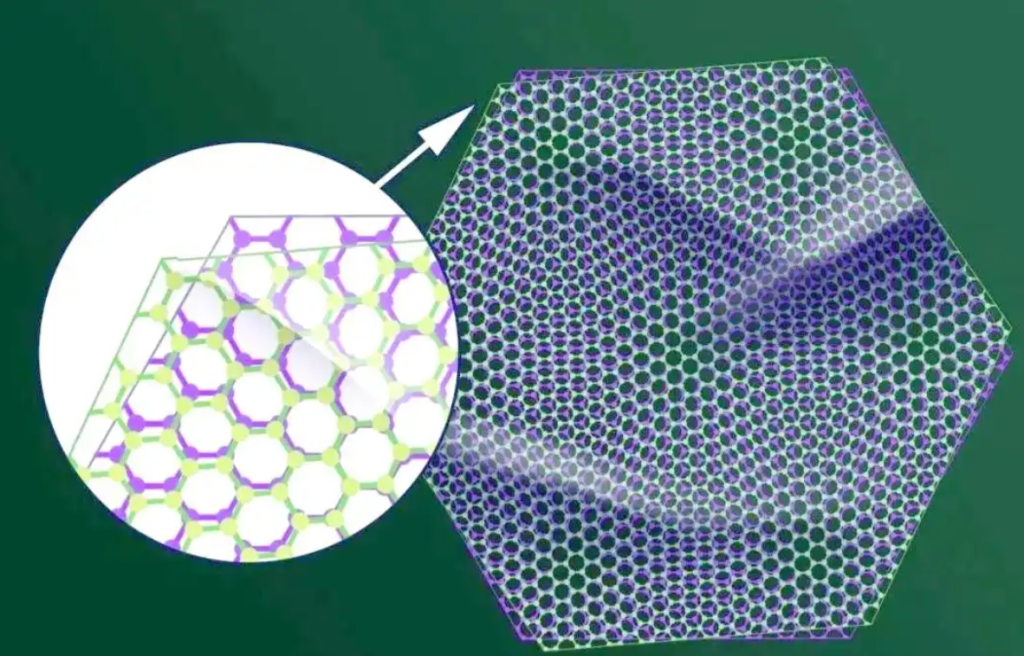

Graphene Oxide (GO) is derived from graphene through chemical oxidation, introducing oxygen-containing groups that make it dispersible in water. However, GO is electrically insulating due to the disruption of its conjugated carbon network.

By reducing GO, many of these oxygen groups are removed, partially restoring graphene’s conductivity. The result is Reduced Graphene Oxide (rGO)—a material that combines:

-

High electrical conductivity (though not as high as pristine graphene)

-

Mechanical flexibility

-

Large surface area

-

Scalable, low-cost production

This balance of properties makes rGO an excellent candidate for flexible conductive films.

Why rGO for Flexible Electronics?

-

Conductivity

-

Reduction of GO restores sp² carbon bonds, enabling efficient electron transport.

-

While not as conductive as pristine graphene, rGO offers sufficient conductivity for many electronic applications.

-

-

Mechanical Flexibility

-

rGO films can bend, twist, and stretch without losing performance, unlike brittle ITO layers.

-

-

Transparency

-

Thin rGO films can remain optically transparent, suitable for displays and touchscreens.

-

-

Scalability

-

rGO can be produced via chemical, thermal, or electrochemical reduction methods, making it cost-effective for mass production.

-

-

Compatibility

-

Can be printed, coated, or sprayed onto flexible substrates, enabling integration into roll-to-roll manufacturing.

-

Applications of rGO in Flexible Electronics

1. Wearable Devices

-

rGO-based films can act as flexible conductive electrodes in smart textiles, fitness trackers, and medical sensors.

-

Their flexibility ensures comfort and durability even during stretching or movement.

2. Flexible Displays and Touchscreens

-

rGO can replace ITO in bendable OLED and LCD panels.

-

Provides stable conductivity under repeated bending cycles.

3. Flexible Circuits

-

rGO-based inks can be used for printed circuit boards (PCBs) in wearable and foldable devices.

-

Enables low-cost, large-area electronic printing.

4. Energy Storage in Flexible Electronics

-

rGO is widely studied in flexible supercapacitors and batteries as a conductive network.

-

Offers lightweight, bendable energy solutions for portable devices.

5. Sensors and Biosensors

-

rGO films exhibit high sensitivity to environmental changes (temperature, strain, chemical exposure).

-

Useful in flexible environmental sensors and healthcare monitoring systems.

rGO vs. ITO: Why Replacement is Needed

| Property | ITO (Traditional) | rGO (Emerging) |

|---|---|---|

| Conductivity | High | Moderate–High (tunable) |

| Transparency | Excellent | Good (thickness-dependent) |

| Flexibility | Poor (brittle) | Excellent |

| Cost & Availability | Expensive (Indium scarcity) | Low-cost, scalable |

| Processability | Limited methods | Compatible with printing, coating |

The comparison highlights why ITO is not sustainable for the future of flexible devices, while rGO provides a more adaptable and eco-friendly alternative.

Key Research and Case Studies

-

Printed rGO Circuits: Researchers have successfully developed rGO-based conductive inks for flexible electronics using inkjet printing.

-

rGO Transparent Electrodes: Studies show rGO films achieving ~85% optical transparency with sufficient conductivity for touchscreens.

-

Hybrid rGO Systems: rGO combined with silver nanowires or conductive polymers can achieve conductivity levels rivaling ITO while maintaining flexibility.

Challenges in Using rGO

-

Lower Conductivity Compared to Pristine Graphene

-

Reduction does not fully restore graphene’s perfect structure, leaving defects.

-

Hybrid approaches are often required for applications demanding ultra-high conductivity.

-

-

Uniformity and Scalability

-

Achieving consistent film quality across large areas remains a challenge.

-

-

Long-Term Stability

-

Environmental exposure (moisture, oxygen) may affect rGO performance.

-

-

Optimization of Transparency vs. Conductivity

-

Thicker films improve conductivity but reduce transparency, requiring trade-offs.

-

Future Outlook

Reduced Graphene Oxide is poised to play a key role in the commercialization of flexible electronics. Ongoing research focuses on:

-

Hybrid rGO Composites: Blending rGO with other nanomaterials to achieve conductivity on par with metals.

-

Roll-to-Roll Manufacturing: Scaling up low-cost, large-area rGO film production.

-

Flexible, Transparent Energy Systems: Integrating rGO electrodes in solar cells and flexible batteries.

-

Smart Textiles: Embedding rGO conductive threads into fabrics for next-generation wearable electronics.

As manufacturing techniques improve, rGO could emerge as the mainstream replacement for ITO, powering everything from foldable smartphones to bio-integrated medical electronics.

Reduced Graphene Oxide (rGO) bridges the gap between high-performance materials like pristine graphene and scalable, cost-effective alternatives to traditional ITO. With its conductivity, flexibility, transparency, and processability, rGO is uniquely suited for flexible electronics such as wearables, foldable displays, and flexible circuits.

Although challenges remain—particularly in achieving higher conductivity and scalable uniform films—progress in hybrid material design and large-area processing is accelerating.

As the world shifts toward flexible, lightweight, and sustainable electronics, rGO-based conductive films are set to become a cornerstone technology in shaping the future of smart devices.