Research on Hydrogen Storage Performance of Graphene-Metal Organic Framework (MOF) Composites

The search for efficient hydrogen storage materials is central to advancing hydrogen as a clean and renewable energy source. Metal-organic frameworks (MOFs), known for their ultrahigh surface area and tunable porous structures, have emerged as promising candidates for hydrogen storage. However, their limited conductivity, relatively low stability, and suboptimal hydrogen adsorption capacity at room temperature pose challenges for practical applications.

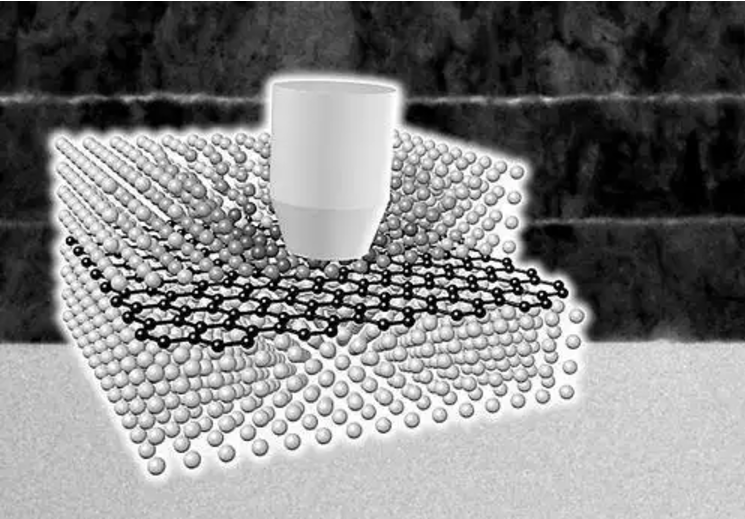

Graphene, with its exceptional electrical conductivity, high surface area, and chemical versatility, provides a synergistic solution when integrated with MOFs. This article explores the research progress on graphene-MOF composites for hydrogen storage, focusing on their synthesis, enhanced mechanisms, and performance.

Key Properties of MOFs for Hydrogen Storage

- Porous Structure:

- MOFs consist of metal ions coordinated with organic ligands, forming a highly porous framework ideal for gas storage.

- High Surface Area:

- MOFs like MIL-101 and HKUST-1 can achieve surface areas exceeding 6,000 m2^2/g, enabling significant hydrogen adsorption.

- Functionalizable Pores:

- The chemical environment of MOF pores can be tailored to improve hydrogen affinity.

- Low Weight:

- MOFs are lightweight, contributing to a favorable gravimetric hydrogen storage capacity.

Synergistic Advantages of Graphene-MOF Composites

Integrating graphene into MOFs addresses several limitations of pure MOFs, enhancing their hydrogen storage performance:

- Improved Electrical Conductivity:

- Graphene facilitates charge transfer, enhancing hydrogen adsorption through induced dipole interactions.

- Increased Thermal Stability:

- Graphene strengthens the structural stability of MOFs under high-pressure or temperature conditions.

- Enhanced Hydrogen Spillover Effect:

- Graphene acts as a conduit for hydrogen spillover, transferring dissociated hydrogen atoms from catalysts to MOF frameworks.

- Hybrid Porosity:

- The combination of MOF’s micropores and graphene’s mesopores creates a hierarchical structure, improving gas diffusion and adsorption.

- Reduced Structural Degradation:

- Graphene layers prevent the collapse or agglomeration of MOF particles, maintaining their porosity over multiple cycles.

Synthesis of Graphene-MOF Composites

Several approaches have been developed to synthesize graphene-MOF composites, ensuring strong interfacial interactions and optimized performance:

- In-Situ Growth:

- MOFs are synthesized directly on graphene sheets, ensuring uniform distribution and intimate contact.

- Example: In-situ synthesis of HKUST-1 on graphene oxide (GO) enhances hydrogen adsorption due to better framework stability.

- Physical Mixing:

- Graphene and pre-synthesized MOFs are combined via mechanical blending or sonication.

- While simpler, this method may result in weaker interactions between components.

- Chemical Bonding:

- Functionalized graphene (e.g., carboxylated or aminated graphene) interacts chemically with MOF ligands, forming robust composites.

- Example: Aminated graphene combined with ZIF-8 exhibits enhanced hydrogen spillover.

- Electrostatic Assembly:

- Positively charged MOFs are combined with negatively charged graphene oxide, forming layered composites through electrostatic attraction.

Mechanisms of Enhanced Hydrogen Storage

- Hydrogen Physisorption:

- MOFs provide adsorption sites through van der Waals forces, while graphene amplifies this effect by offering additional adsorption sites and dipole-induced interactions.

- Hydrogen Spillover:

- Graphene facilitates the dissociation of H2H_2 molecules on a catalyst (e.g., Pd or Pt) and enables the migration of atomic hydrogen to MOF structures.

- Example: A graphene-MOF composite with Pd nanoparticles showed a significant increase in hydrogen storage capacity.

- Pore Optimization:

- Graphene enhances the framework’s porosity, allowing faster gas diffusion and better accessibility of hydrogen molecules to storage sites.

- Thermal Management:

- The high thermal conductivity of graphene ensures uniform heat distribution during hydrogen adsorption/desorption cycles, improving kinetics.

Hydrogen Storage Performance of Graphene-MOF Composites

1. Graphene-MIL-101 Composites

- Performance: Enhanced gravimetric hydrogen storage capacity, reaching up to 6.1 wt% at 77 K and 50 bar.

- Mechanism: Graphene improves thermal stability and enhances adsorption kinetics through its high conductivity.

2. Graphene-HKUST-1 Composites

- Performance: Achieved 20% higher hydrogen uptake compared to pure HKUST-1 at room temperature.

- Mechanism: The composite structure provides hybrid micropores and mesopores for better gas diffusion.

3. Graphene-ZIF-8 Composites

- Performance: Increased hydrogen storage capacity and improved reversibility over multiple cycles.

- Mechanism: Nitrogen-rich ZIF-8 chemically interacts with graphene, enhancing hydrogen adsorption sites.

4. Graphene-Pd-MOF Hybrids

- Performance: Achieved 5.6 wt% hydrogen storage at 298 K and 20 bar.

- Mechanism: Palladium nanoparticles on graphene facilitate hydrogen dissociation and spillover into MOF frameworks.

Challenges and Future Directions

- Scalable Synthesis:

- Developing cost-effective and scalable methods for producing graphene-MOF composites is essential for commercialization.

- Optimization of Graphene Content:

- Excessive graphene can block MOF pores, reducing storage capacity, while insufficient graphene limits synergistic effects.

- Material Stability:

- Ensuring long-term stability of graphene-MOF composites under operational conditions is critical.

- Tailored Functionalization:

- Functionalizing graphene and MOFs to enhance hydrogen interactions and promote stronger bonding is a promising avenue.

- Hybrid Materials:

- Combining graphene-MOF composites with other materials, such as carbon nanotubes or polymers, could create multifunctional systems for advanced storage applications.

Conclusion

Graphene-MOF composites represent a powerful synergy in the field of hydrogen storage. The integration of graphene’s high conductivity and stability with MOFs’ exceptional porosity and adsorption properties leads to significant improvements in hydrogen storage capacity, kinetics, and durability.

While challenges remain in optimizing synthesis methods and material stability, ongoing research is paving the way for graphene-MOF composites to become a cornerstone technology in the hydrogen economy, supporting applications in transportation, energy storage, and beyond.